Composite metal material and preparation method thereof

A composite metal material and metal material technology, applied in the field of composite metal materials and their preparation, can solve the problems of high cost and serious pollution, and achieve the effect of optimizing thickness and improving comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a method for preparing a composite metal material, comprising the steps of:

[0043] Step 1: heating the second metal to 1150-1250°C in a vacuum environment until the second metal is completely molten;

[0044] Step 2: Place the second metal liquid in the atomization device, control the atomization temperature to 1100-1200°C, and centrifugally atomize the second metal liquid into droplets;

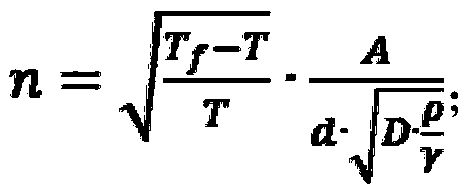

[0045] Control the centrifugal speed as:

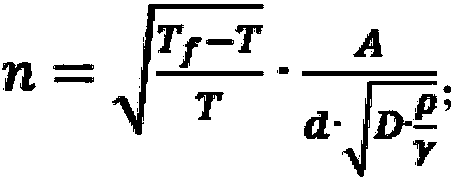

[0046]

[0047] In the formula, n is the rotational speed of the centrifugal disc used for centrifugal atomization, T f is the atomization temperature, T is the spraying temperature, A is a constant, d is the diameter of the atomized droplet, D is the diameter of the centrifugal disc, ρ is the density of the second metal, and γ is the surface tension of the second metal;

[0048] Step 3: Pre-treat the first metal:

[0049] Submerge the first metal material substrate in NaOH solution (solution concen...

Embodiment 1

[0063] The preparation method of the composite metal material provided in this embodiment comprises the following steps:

[0064] The first metal is an aluminum plate with a thickness of 1 mm, and the second metal layer is a copper layer with a thickness of 0.6 mm.

[0065] Step 1: Heat the copper metal to 1150°C in a vacuum environment until the copper metal is completely molten;

[0066] Step 2: Put the copper metal liquid in the atomization device, control the atomization temperature to 1100°C, and centrifugally atomize the copper metal liquid into droplets with a droplet diameter of 15 μm;

[0067]Control the centrifugal speed as:

[0068]

[0069] In the formula, n is the rotational speed of the centrifugal disc used for centrifugal atomization, T f is the atomization temperature, T is the spraying temperature, A is a constant of 0.451, d is the diameter of the atomized droplet, D is the diameter of the centrifugal disc is 200mm, ρ is the density of the second metal,...

Embodiment 2

[0084] The preparation method of the composite metal material provided in this embodiment comprises the following steps:

[0085] The first metal is an aluminum plate with a thickness of 2 mm, and the second metal layer is a copper layer with a thickness of 1.4 mm.

[0086] Step 1: Heating the copper metal to 1250°C in a vacuum environment until the copper metal is completely molten;

[0087] Step 2: Put the copper metal liquid in the atomization device, control the atomization temperature to 1200°C, and centrifugally atomize the copper metal liquid into droplets with a diameter of 20 μm;

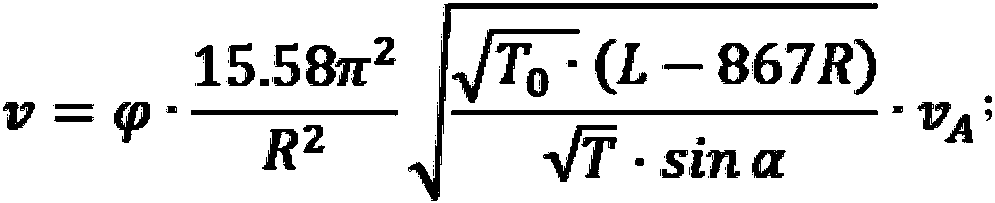

[0088] Control the centrifugal speed as:

[0089]

[0090] In the formula, n is the rotational speed of the centrifugal disc used for centrifugal atomization, T f is the atomization temperature, T is the spraying temperature, A is a constant of 0.451, d is the diameter of the atomized droplet, D is the diameter of the centrifugal disc is 200mm, ρ is the density of the second metal, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com