Cloth dyeing and finishing process and production device thereof

A production equipment and fabric technology, applied in the field of fabric dyeing and finishing technology and its production equipment, can solve the problems affecting the wearing performance of fabrics, the smoothness of dyeing and finishing, and the poor dyeing effect of fabrics, so as to achieve improved dyeing effects, high vividness, and improved The effect of the bleach effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

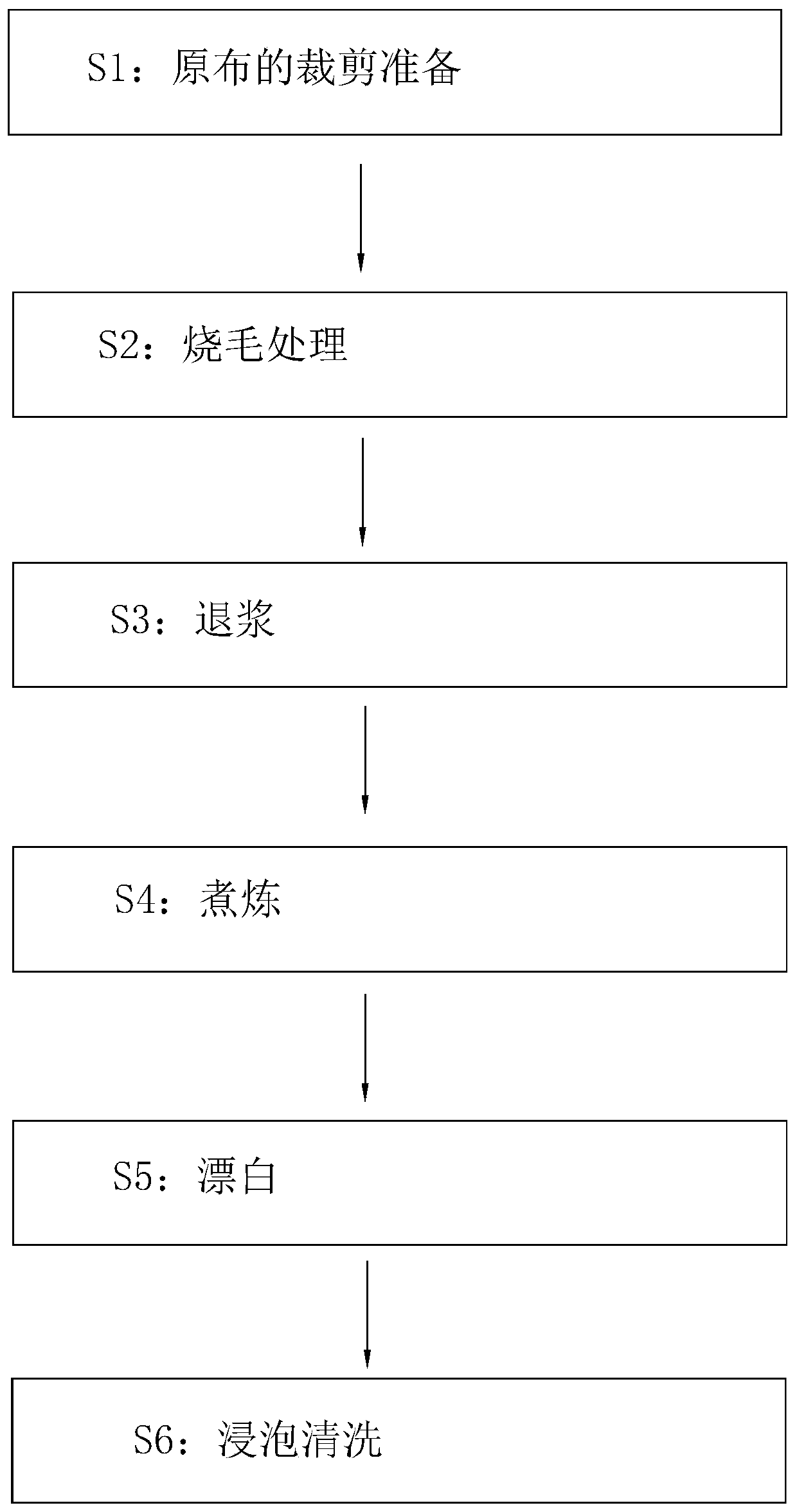

[0047] A kind of cloth dyeing and finishing process, with reference to figure 1 , S1: Cutting preparation of the original fabric: check the length, weight and density of the original fabric, arrange different fabrics in batches, and sew the fabrics of the same dyed batch;

[0048] S2: Singeing treatment: Singeing the raw cloth with a singeing machine, quickly rubbing the flat width of the raw cloth over the hot metal surface on the singeing machine, so as to remove the fluff on the surface of the raw cloth;

[0049] S3: Desizing: Select the corresponding desizing according to the different types of fabrics. Desizing includes: alkali desizing, acid desizing, enzyme desizing, oxidant desizing, and then soak the fabric in desizing to remove the original fabric. the slurry;

[0050] S4: Scouring: put the desized raw fabric into a cloth boiling pot containing high-temperature concentrated lye for scouring, and the scouring time is 35 minutes;

[0051] S5: Bleaching: Pour the hydr...

Embodiment 2

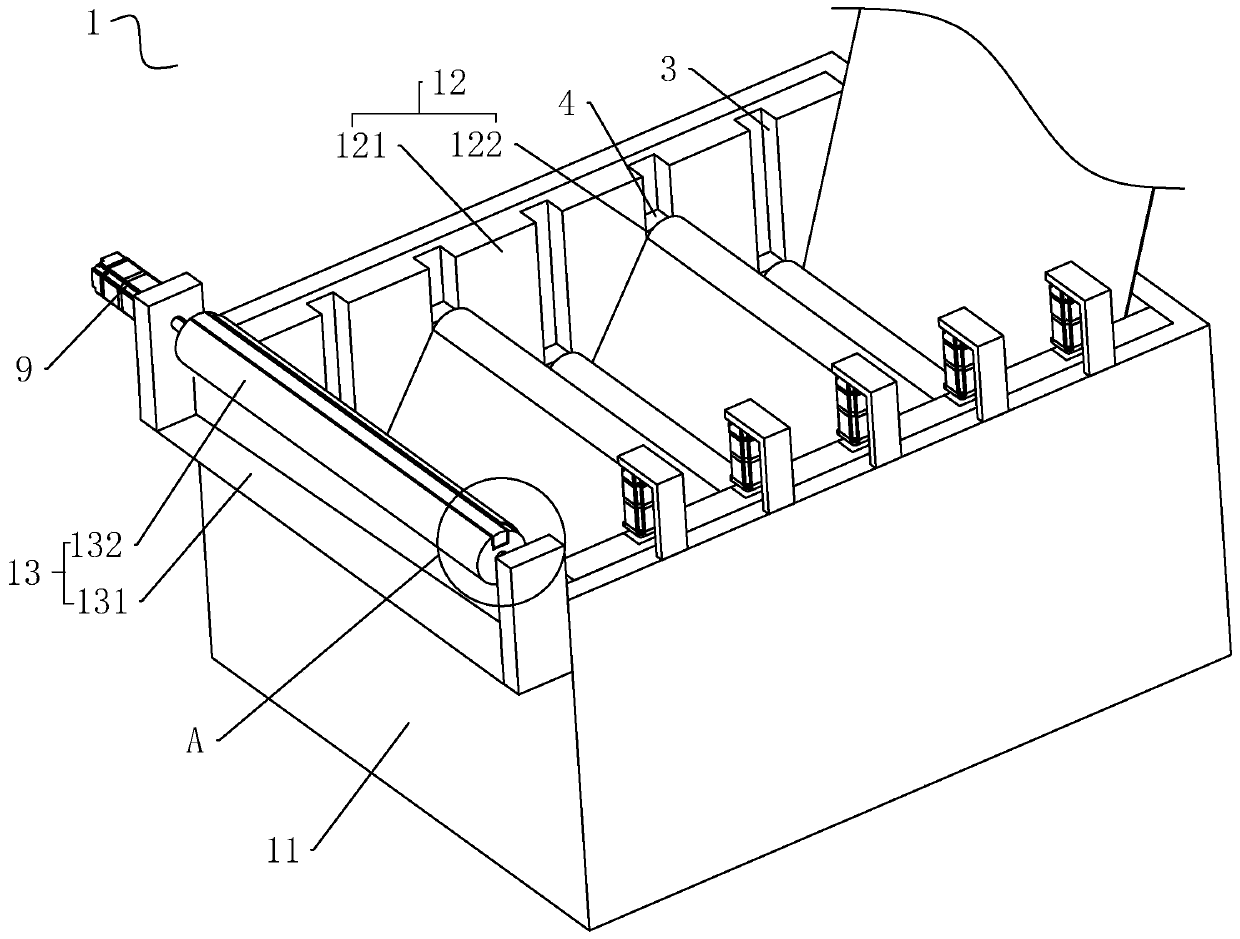

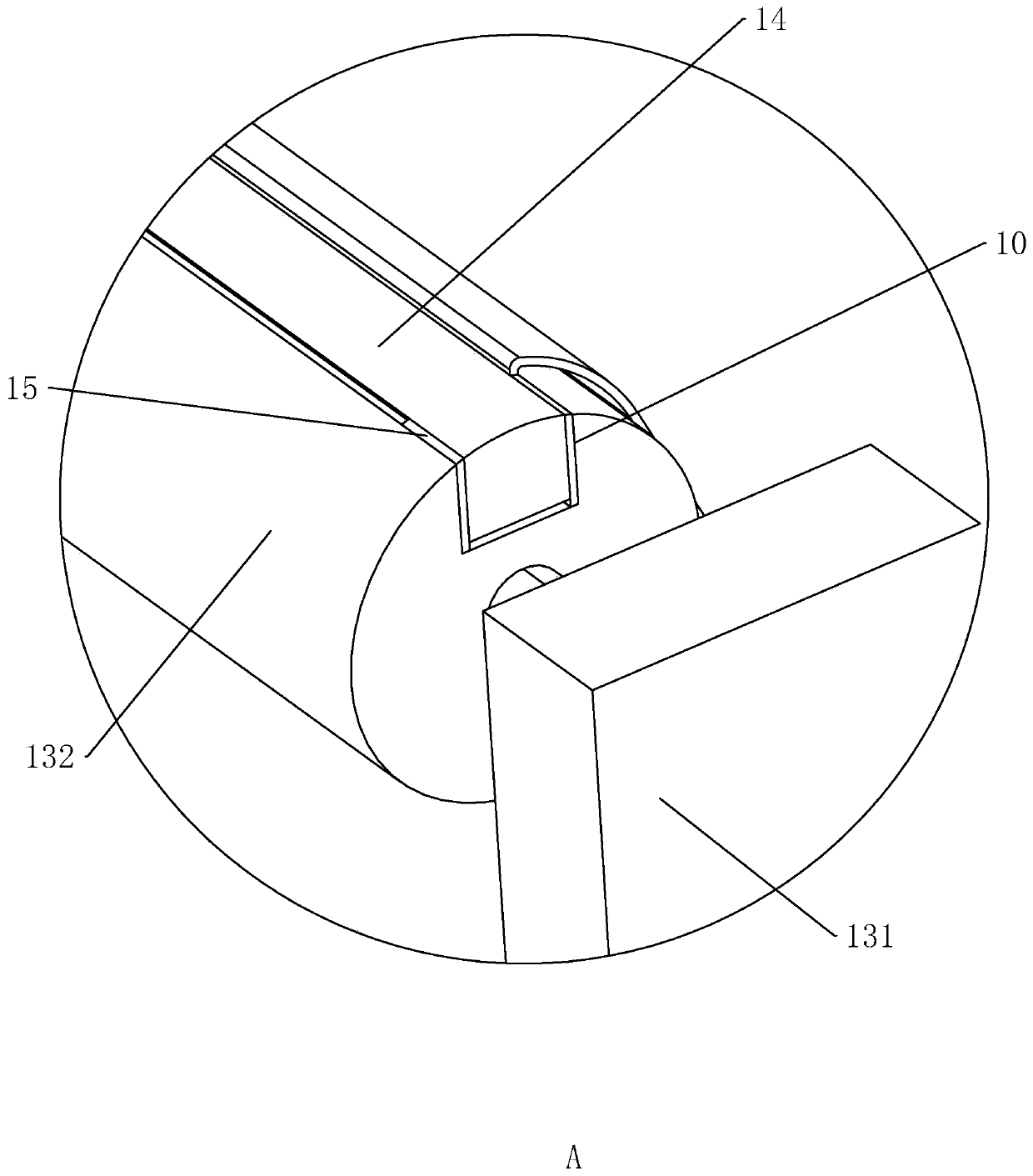

[0054] A kind of production device that is applied to cloth dyeing and finishing process in embodiment 1, with reference to figure 2 and image 3 , including a bleaching device 1, the bleaching device 1 includes a bleaching tank 11, a supporting device 12 arranged in the bleaching tank 11, and a winding device 13 arranged on the bleaching tank 11.

[0055] Wherein, the inner cavity of the bleaching tank 11 is arranged as a cuboid. The supporting device 12 includes a mounting plate 121 fixedly connected to the inner wall of the bleaching tank 11 , and a plurality of supporting rods 122 slidingly connected to the side wall of the mounting plate 121 facing away from the bleaching tank 11 .

[0056] refer to figure 2 and image 3 , the mounting plate 121 ring is located on the inner wall of the bleaching cylinder, and the left and right side walls of the mounting plate 121 are respectively provided with 5 chutes 2 along the vertical direction. The vertical tangential plane i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com