House with aluminum alloy structure

An aluminum alloy and aluminum alloy surface technology, applied in the field of hoists, can solve the problems of easily damaged wall panels and roofs, large beams and columns, and high material costs, achieve high bending resistance, avoid structural difficulties, and have good rainwater resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

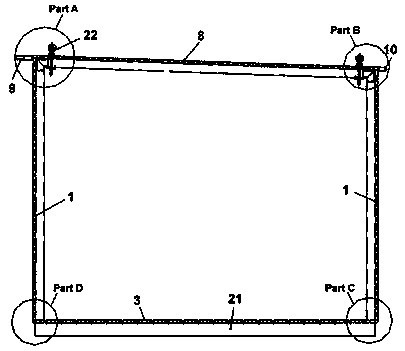

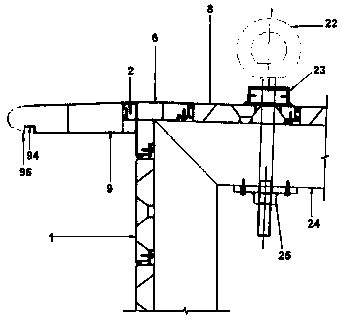

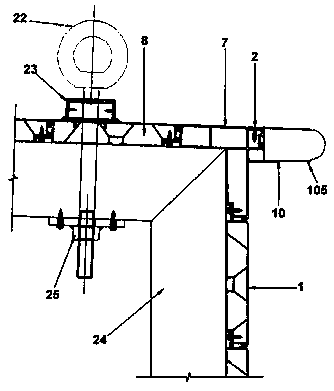

[0057] refer to Figure 1 to Figure 4 . refer to Figure 1-5 , the present invention provides a house with an aluminum alloy structure. A house with an aluminum alloy structure is mainly composed of a plurality of individual aluminum alloy wall panels 1, a plurality of individual aluminum alloy floors 3, a plurality of individual aluminum alloy roof panels 8, a first corner connecting material 4, and a second corner. Connecting material 5, third corner connecting material 6, fourth corner connecting material 7, first aluminum alloy surface eaves 9, second aluminum alloy surface eaves 10 and fixing screws 2.

[0058] refer to Figure 6 and combine Figure 5 and Figure 6 . 1-3, a pressing portion 85 is disposed on the upper side portion 81 of the joint base at one end portion 8 of the individual aluminum alloy roof panel, and a retaining groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com