Natural gas overhead pipeline street crossing support device

A technology for overhead pipelines and support devices, which is applied to pipeline supports, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve the problems of low safety and high cost of erecting natural gas overhead pipelines, and achieve easy promotion, construction and material costs The effect of reducing, making and constructing is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

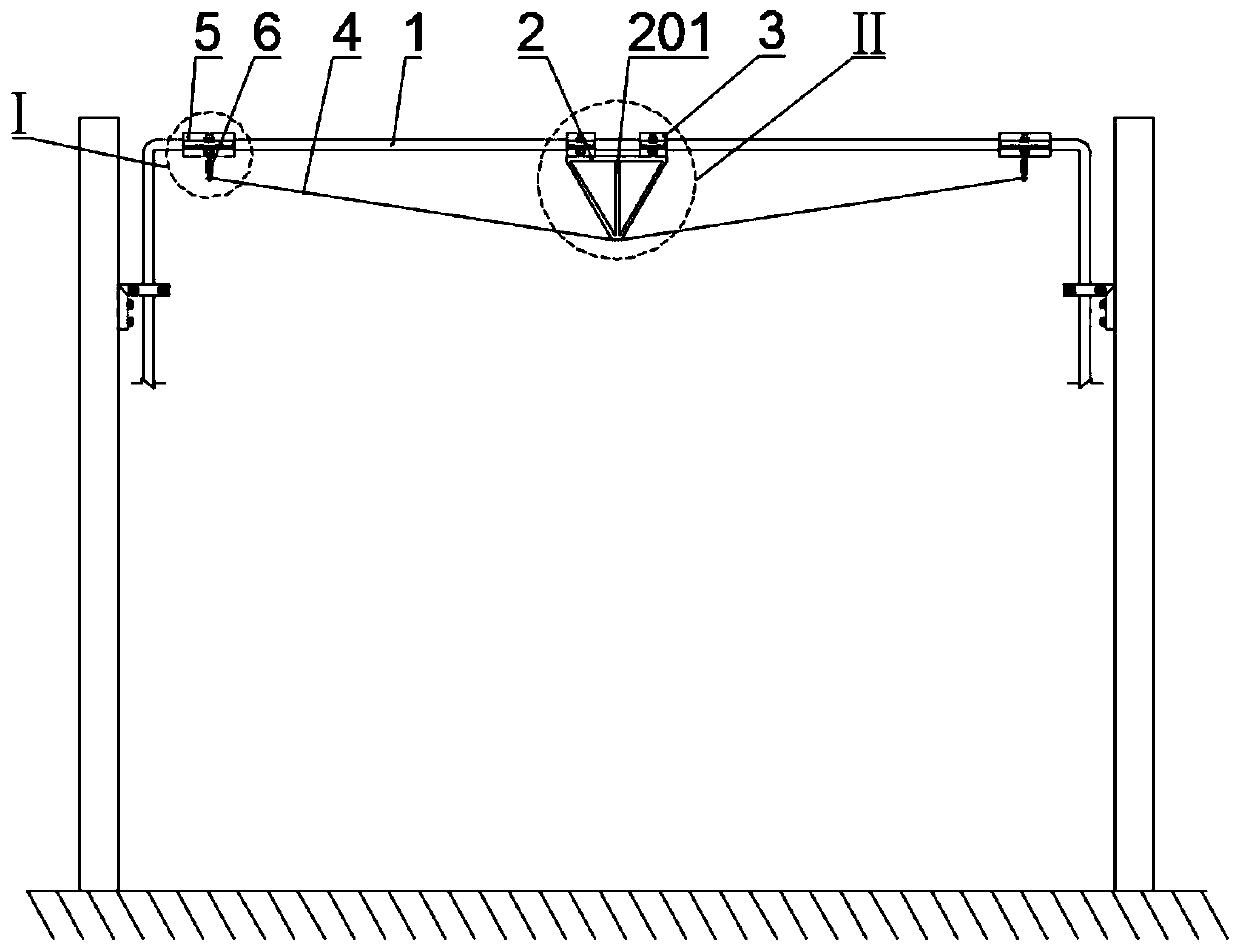

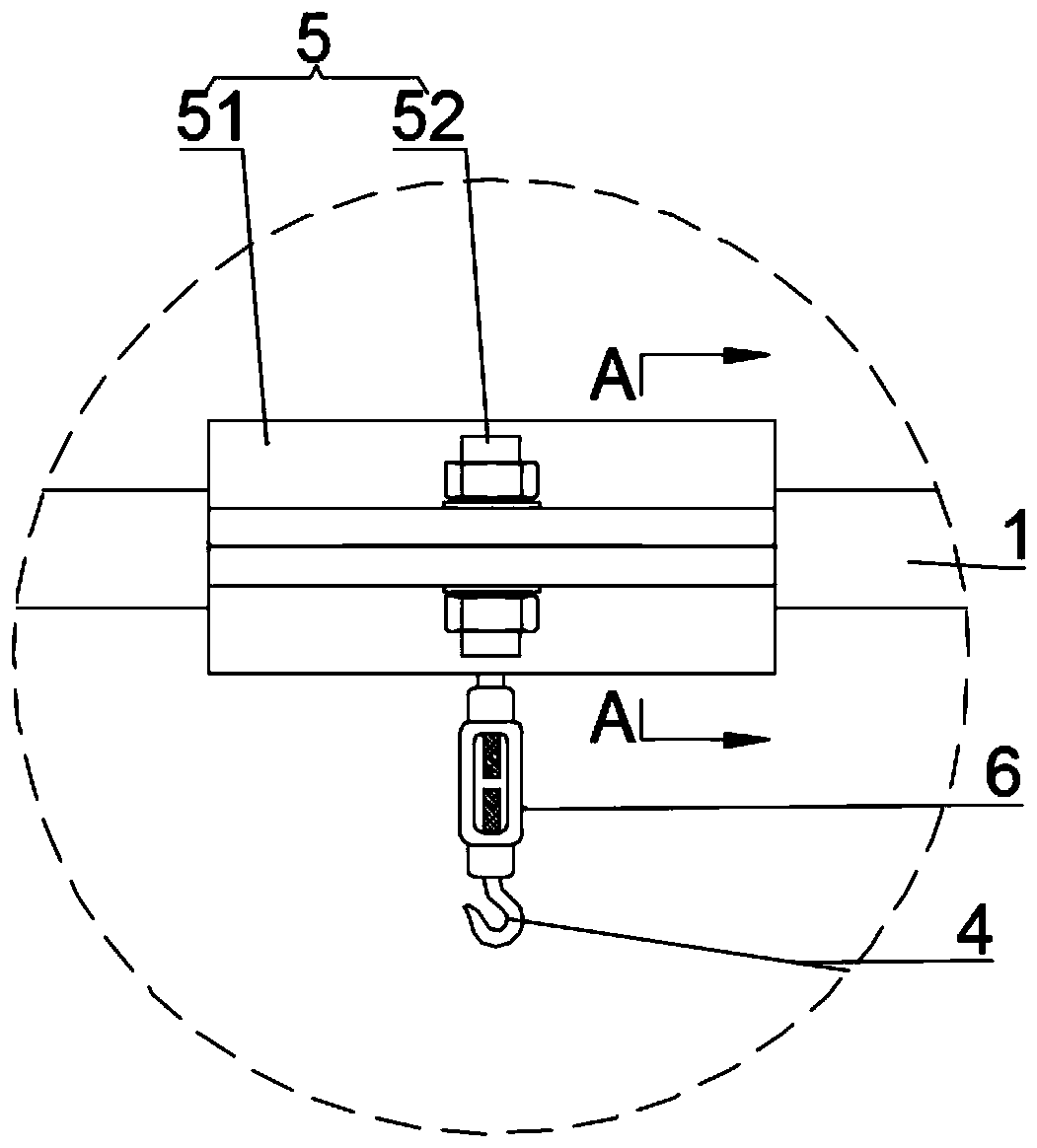

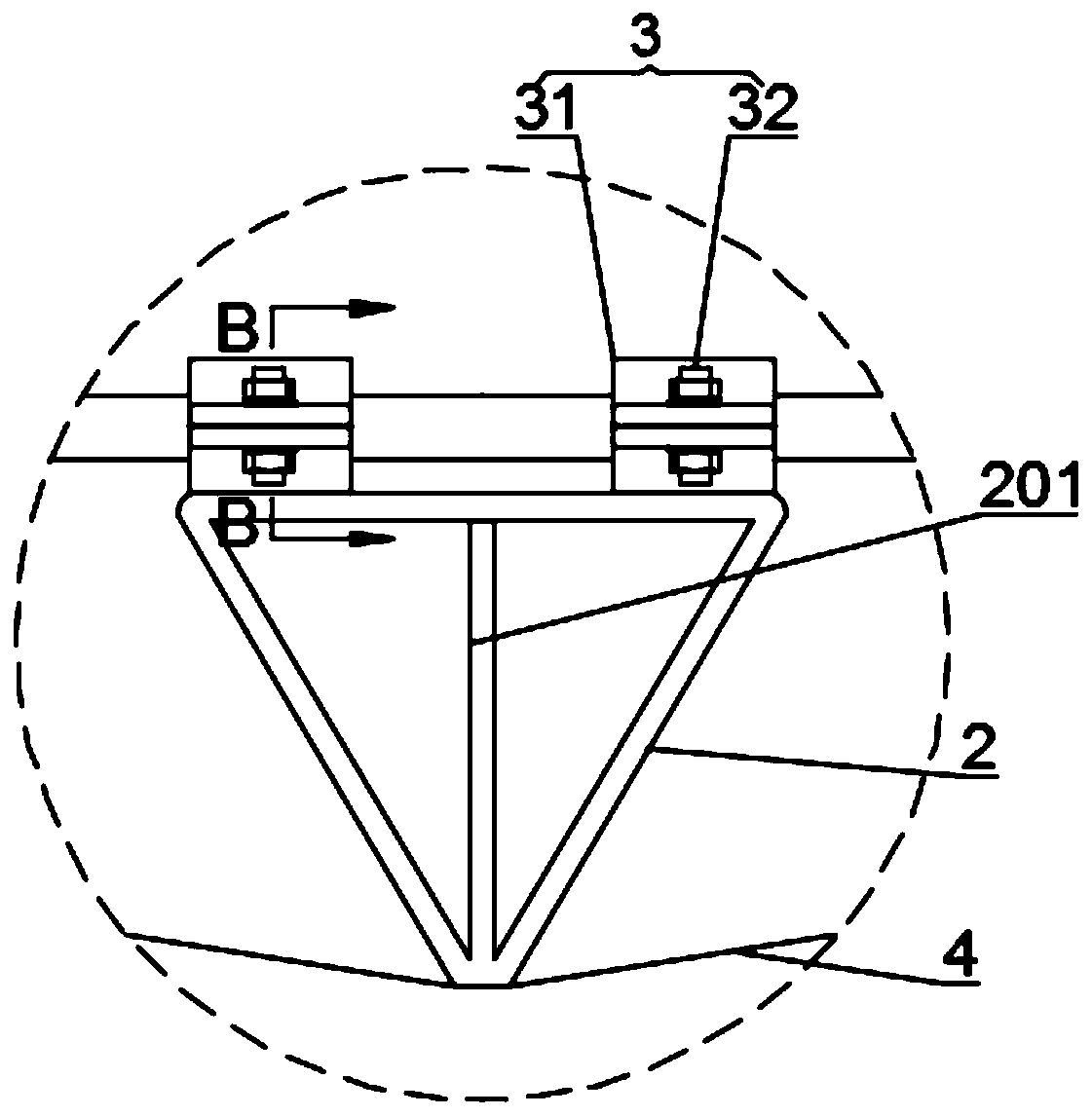

[0049] Such as Figure 1-5 Shown, a kind of natural gas overhead pipeline street straddling supporting device, comprises the natural gas overhead pipeline 1 spanning between two buildings; At least one steel wire rope 4 at the end and symmetrically arranged along the support member 2; wherein, the other end of the steel wire rope 4 is fixedly connected to the support member 2 so that the steel wire rope 4 has tension.

[0050]In the present invention, by setting the support piece 2 in the lower part of the natural gas overhead pipeline 1, and connecting the support piece 2 and the two ends of the natural gas overhead pipeline 1 through the steel wire rope 4, the support piece 2 is simultaneously connected with the natural gas overhead pipeline as a rigid bending member. The middle part of the pipeline 1 and the two end parts of the natural gas overhead pipeline 1 as tension members enable the support 2 to play a supporting role for the middle part of the natural gas overhead p...

Embodiment 2

[0092] The only difference from Example 1 is that, as Figure 7-11 The end connection device 5 includes a U-shaped frame 54, a turn-over limiting plate 55 arranged on the upper side of the U-shaped frame 54, a limiter connected to the upper part of the turn-over limit plate 55 and fixedly connected to the inner wall of the U-shaped frame 54. The block 58, the extruding plate 59 arranged on the lower side inside the U-shaped frame 54 and used to extrude the natural gas overhead pipeline 1 in the U-shaped frame 54, and the one-way limit mechanism 7 that can limit the downward movement of the extruding plate 59 , the flipping limiting plate 55 is rotatably connected to the wall of the U-shaped frame 54 through a rotating shaft 56 , and the rotating shaft 56 is also connected to the wall of the U-shaped frame 54 through a scroll spring 57 .

[0093] Such as Figure 8 and 10 As shown, because the long natural gas overhead pipeline 1 in the prior art adopts the scheme of adding su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com