Device and method for simulation experiment of overall bending resistance of deep-water surface conduit delivery tool

A technology for simulating an experimental device and a feeding tool, which is applied in the field of an overall bending resistance simulation experimental device for a deep-water surface conduit feeding tool, which can solve problems such as failure to work properly, lack, and bending of the deep-water surface conduit feeding tool, so as to reduce the number of accidents. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 provides an overall bending resistance simulation experiment device for a deep-water surface conduit running tool, and its structure will be described in detail below.

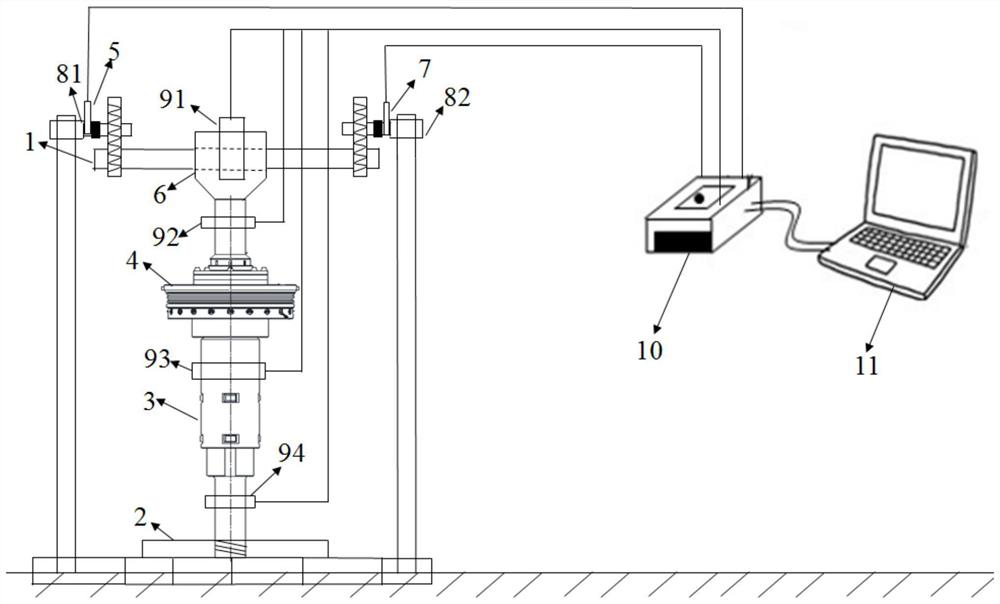

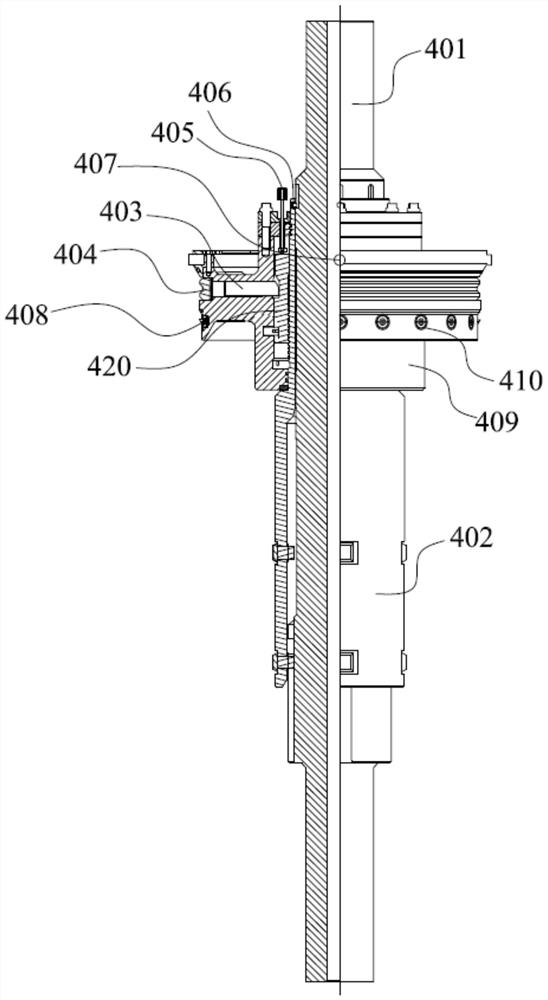

[0028] refer to figure 1 , the overall bending resistance simulation experiment device of the deep-water surface conduit entry tool includes an experiment frame 1, a base 2, a deep-water surface conduit entry tool 4, a tension sensor 5, an adapter 6, a pressure sensor 7, a first motor 81, and a second motor 82. Multiple stress sensors, data collectors 10 and controllers 11,

[0029] The base 2 is a reinforced concrete structure base. The test frame 1 includes a horizontal beam and two supports supporting the two ends of the beam. The two supports are fixed on the base 2, and the bottom of the deep-water surface conduit feeding tool 4 is fixed on the base 2. , the adapter 6 is arranged on the top of the deep-water surface conduit sending tool 4, and the beam of the test frame 1 is horizonta...

specific Embodiment

[0034] A specific embodiment, start the first motor 81 to provide upward pulling force to the left end of the horizontal crossbeam of the test frame 1, start the second motor 82 to provide downward pressure to the right end of the horizontal crossbeam of the test frame 1, and impel the crossbeam of the test frame 1 to provide the deep water surface Catheter Running Tool 4 Bending Moment. The tension sensor 5, pressure sensor 7, adapter stress sensor 91, mandrel stress sensor 92, bushing stress sensor 93, and bottom bushing stress sensor 94 transmit the stress values and bending deformation values collected respectively to the data collector 10 and The controller 11 analyzes the weak points of the overall bending failure resistance of the deep-water surface conduit running tool 4 according to the stress value and the bending deformation value.

[0035] In the above embodiments, the data collector 10 is a data collection product with a USB interface, which can be connected w...

Embodiment 2

[0049] Embodiment 2 provides a kind of overall bending resistance simulation experiment method of deep water surface layer conduit feeding tool, adopts the overall bending resistance simulation experiment device of deep water surface layer conduit feeding tool provided in embodiment 1, and this overall bending resistance simulation experiment method comprises the following steps:

[0050] Step S1: start the first motor 81, and the first motor 81 provides an upward pulling force to one end of the crossbeam of the test frame 1;

[0051] Step S2: start the second motor 82, and the second motor 82 provides downward pressure on the other end of the crossbeam of the test frame 1;

[0052] Step S3: Under the joint action of the tension and pressure on the two ends of the crossbeam of the test frame 1, the crossbeam of the test frame 1 is formed to provide a bending moment for the deep-water surface conduit feeding tool 4, and the deep-water surface conduit feeding tool 4 is bent outwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com