Plug-in residual current load current sensor of miniature circuit breaker

A miniature circuit breaker and residual current technology, applied in the direction of measuring current/voltage, only measuring current, instruments, etc., can solve problems such as increasing product volume, no sensor installation, and impact on circuit breaker performance, so as to ensure installed capacity and simple structure Reasonable, easy-to-test effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

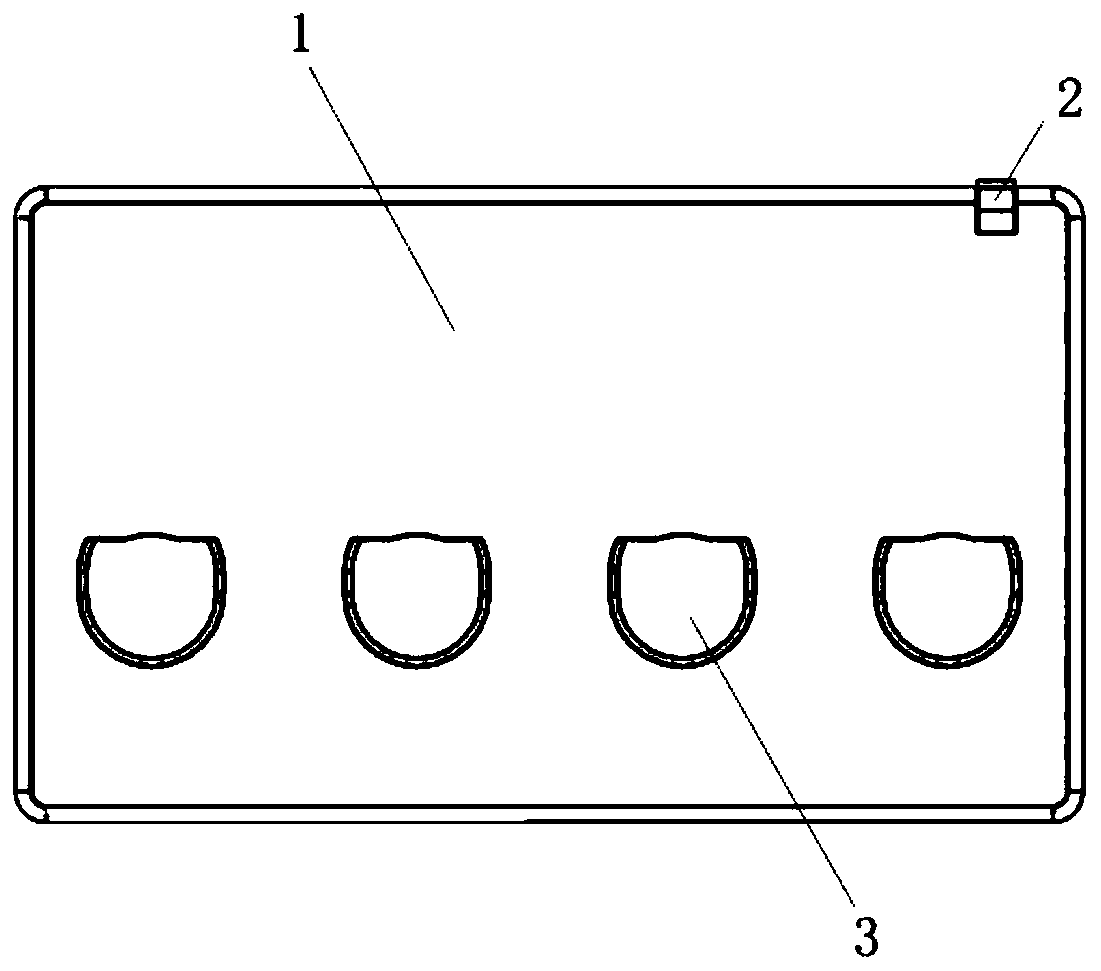

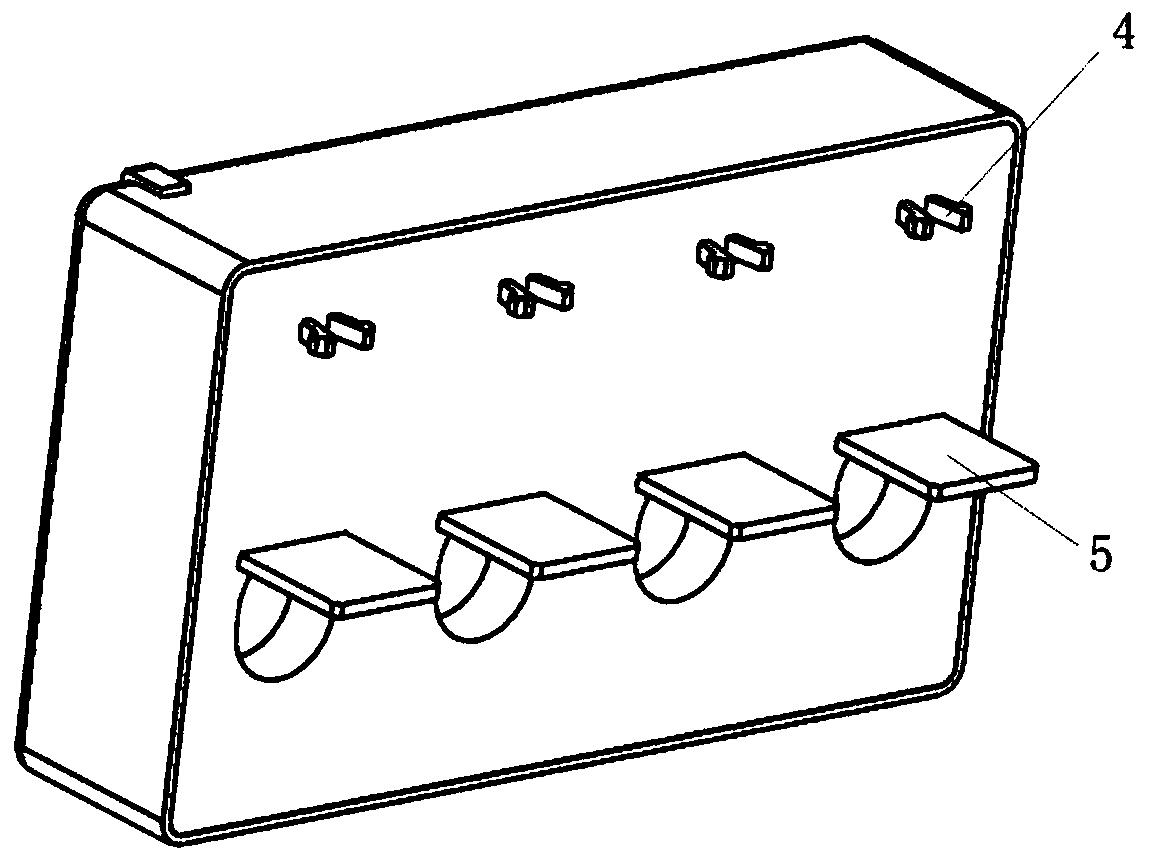

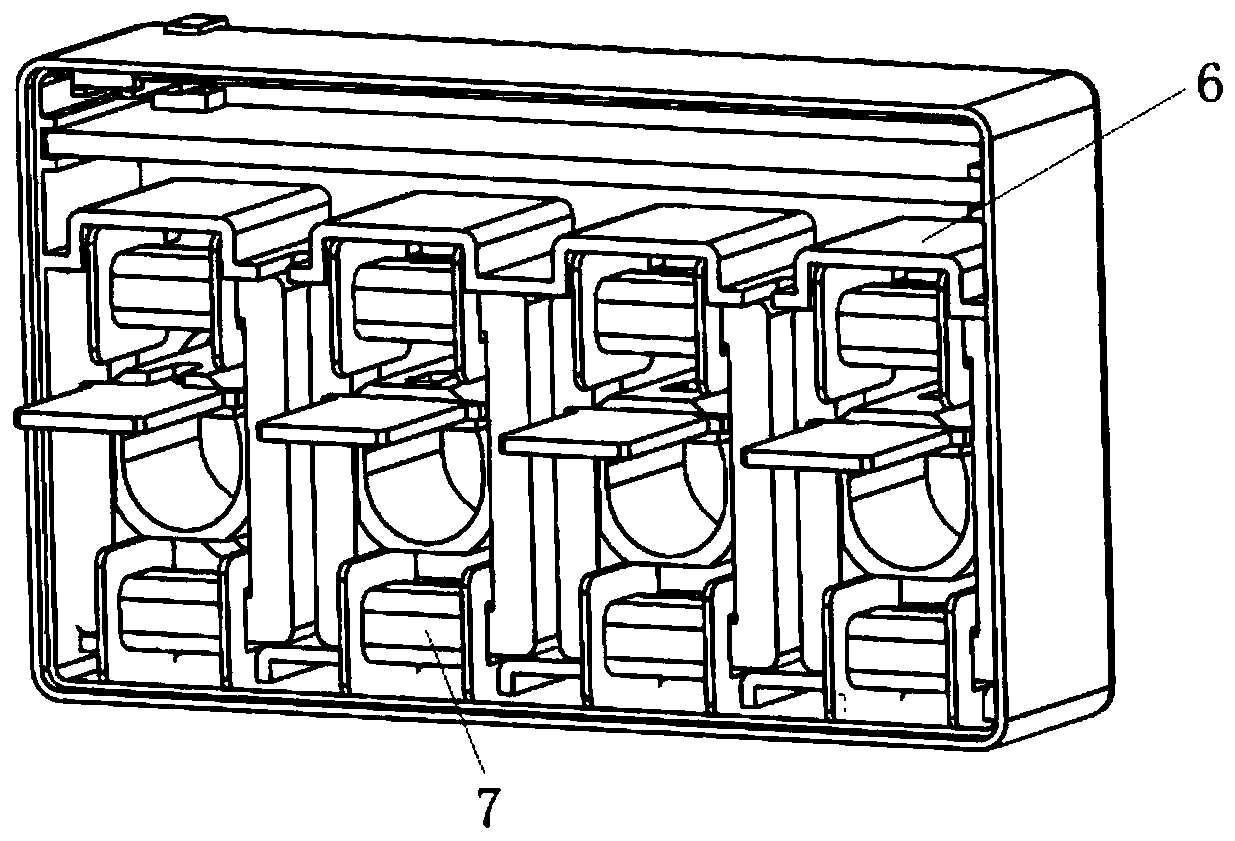

[0020] As shown in the accompanying drawings, a miniature circuit breaker plug-in residual current load current sensor includes a sensor body 1, a jack 3 is opened in the middle of the sensor body 1, and a light guide test jumper is installed on the upper side of the body The button 2, the back of the sensor body 1 is equipped with a plurality of buckles 4, four copper sheets 5 are installed under the buckles 4, and the copper sheets 5 are located at the upper end of the jack 3, and the inside of the sensor body 1 A fixing part 7 is installed, and the upper end of the fixing part 7 is equipped with a contact part 6;

[0021] Wherein, the sensor main body 1 realizes plug-in installation through the copper sheet 5, which reduces the shielding of the signal due to the structure of the circuit breaker body, electrical isolation, arc interference and metal parts;

[0022] The sensor main body 1 is installed at the front and rear ends of the circuit breaker, and the thickness is onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com