Box type structure heavy deformation prediction method based on macroscopic stress and residual stress extension

A technology of residual stress and box-shaped structure, applied in the direction of force/torque/work measuring instrument, measuring force, measuring device, etc., can solve the problems of low calculation accuracy and low detection efficiency, so as to avoid limitations and improve accuracy The effect of sex and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

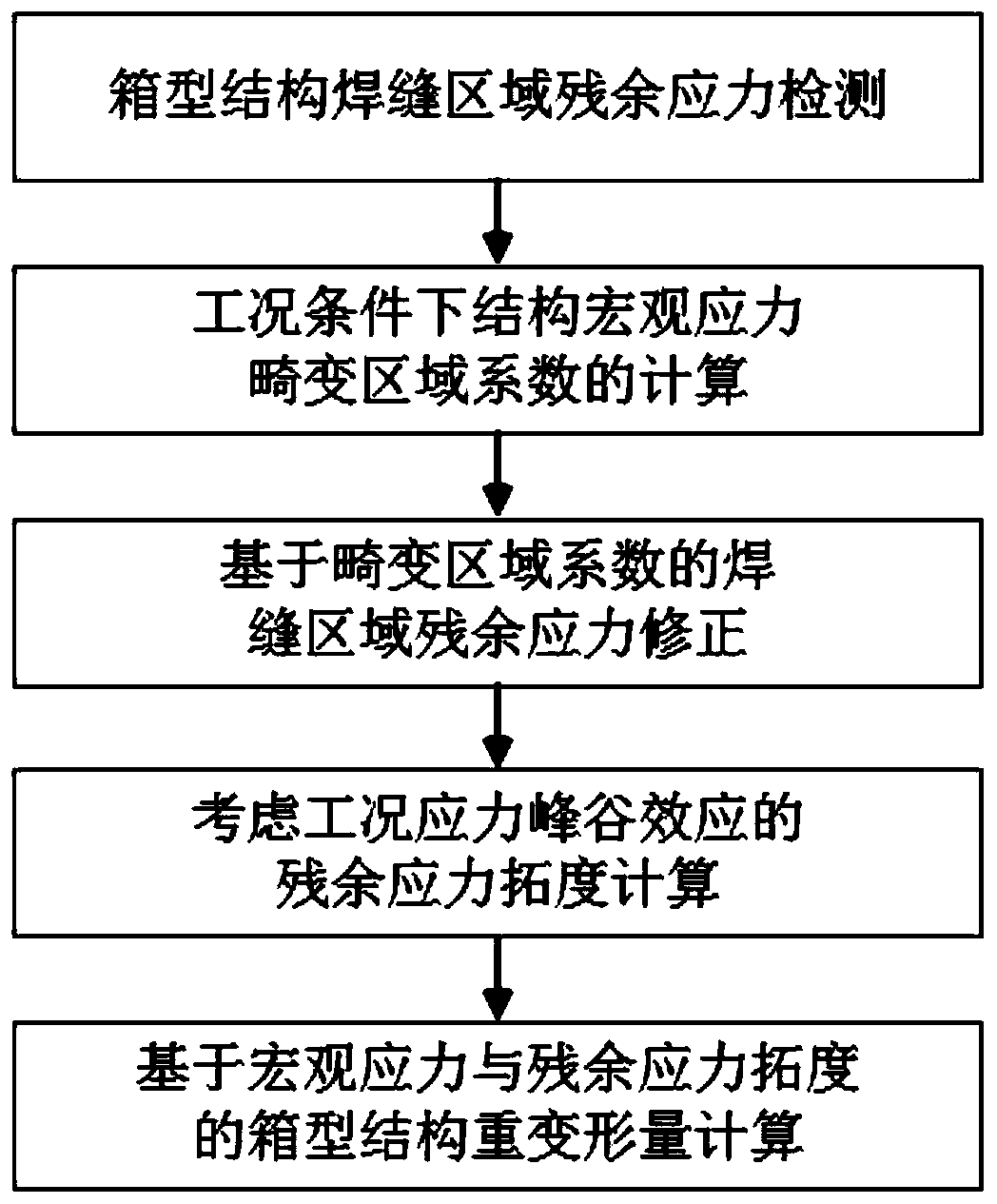

[0044] Such asfigure 1 As shown, this embodiment is based on the macroscopic stress and the residual stress extension of the box structure weight deformation prediction method, the method includes the following steps:

[0045] S1. Residual stress detection in weld area of box structure:

[0046] Use the X-ray residual stress testing device to take a point i (i=1,2,3...N, i is the label of the point) at the welding seam of the box structure every 5mm to test the residual stress, and obtain a certain point i Corresponding to the residual stress σ in the X direction x , corresponding to the residual stress σ in the Y direction y , corresponding to the residual stress σ in the Z direction z .

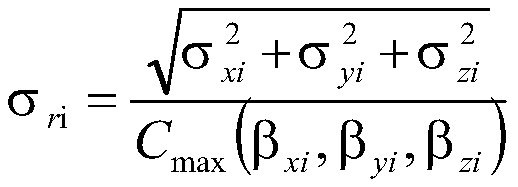

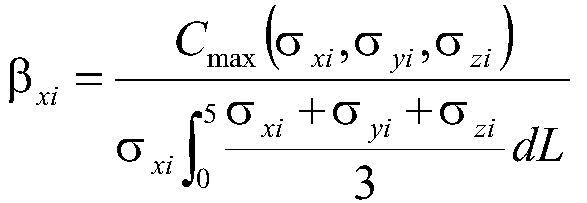

[0047] The total value of residual stress σ at each measurement point at the weld of the box structure ri Can be expressed as:

[0048]

[0049] Among them, σ ri is the total value of residual stress at each measurement point at the weld of the box structure; σ xi is the residua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com