Battery cell rubberizing and rolling device

A battery cell and glue sticking technology, which is applied in the field of battery cell glue sticking and rolling device, can solve the problem of low efficiency of manual sticking of battery cells, and achieve the effects of simple structure, improved efficiency and reliable action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0060] The invention is a battery cell adhesive rolling and flattening device. In order to protect the battery cell, it automatically completes the glue application on the edge of the battery cell and rolls the tape flat.

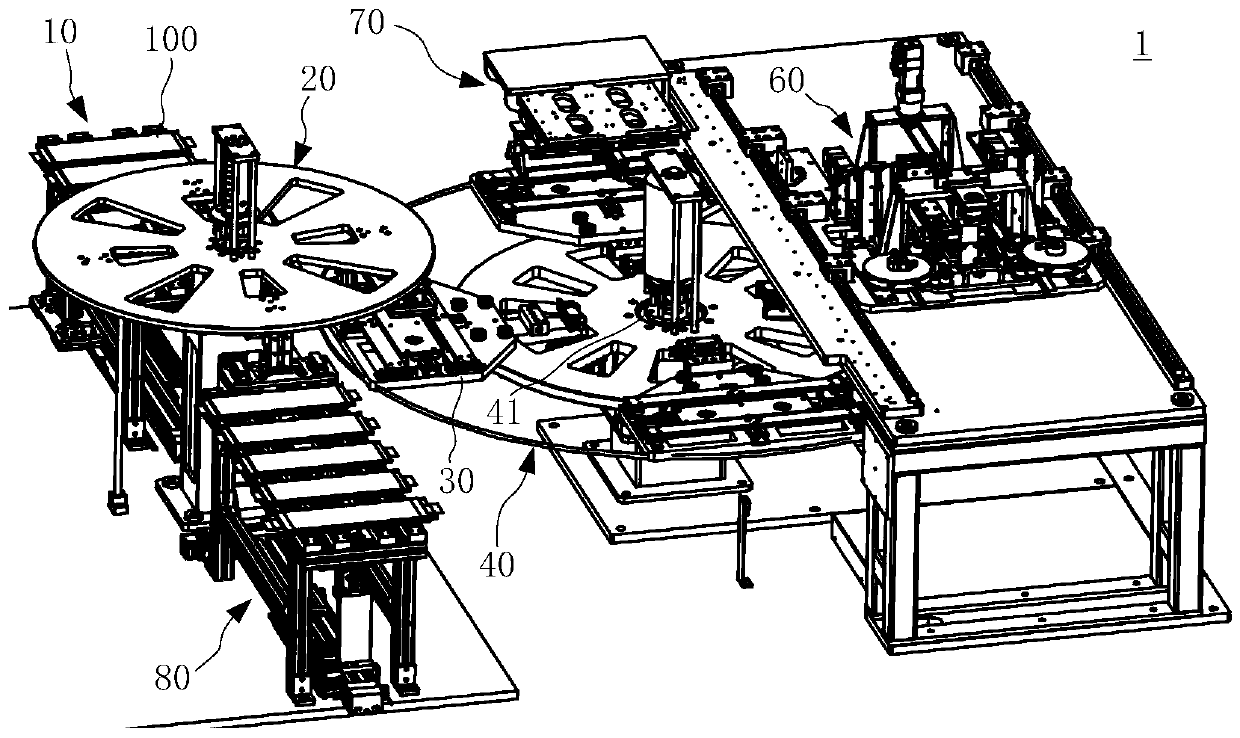

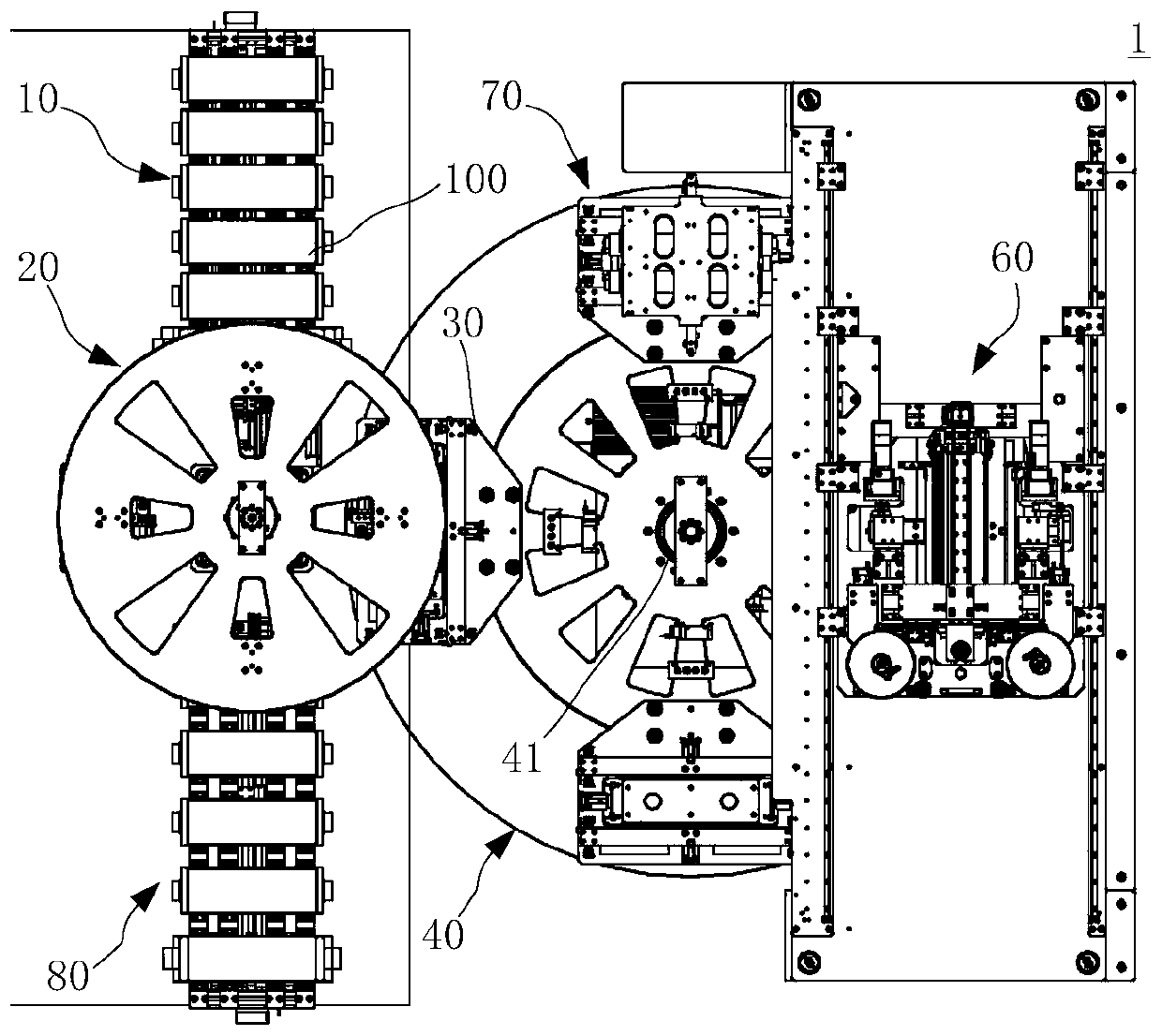

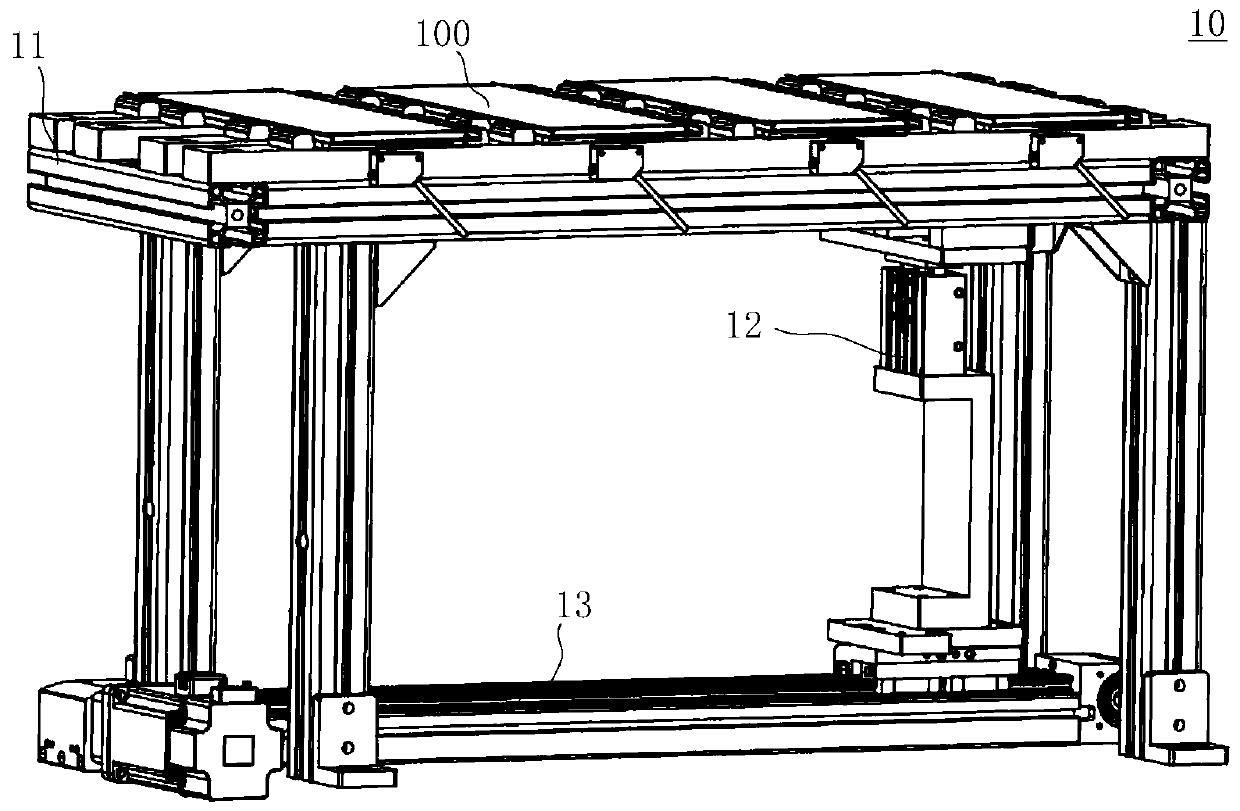

[0061] figure 1 , figure 2 Shown is an optional embodiment of the battery cell glue rolling device 1, figure 1 is a perspective view of the device, figure 2 is a top view of the device. Specifically, the battery cell gluing and rolling device 1 is used to stick adhesive tape on the side of the battery cell 100, and stick the unattached part of the tape attached to the two sides of the battery cell 100 to the upper surface of the battery cell 100 and level it. .

[0062] The cell gluing and rolling device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com