Passive pumping for recirculating exhaust gas

A technology of exhaust gas recirculation and exhaust gas, applied in the direction of exhaust gas recirculation, engine components, combustion engines, etc., can solve the problems of reducing efficiency and increasing the possibility of knocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

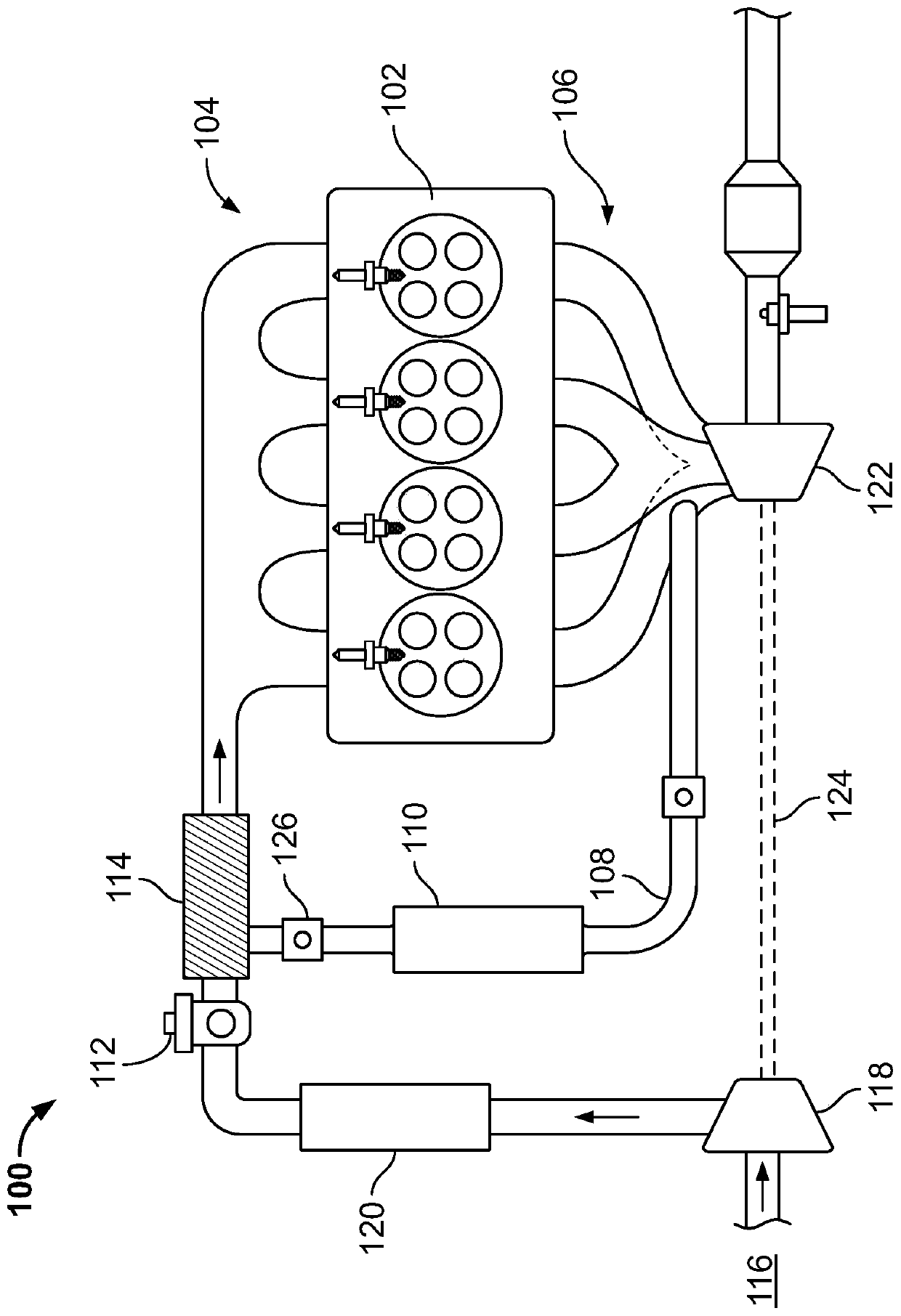

[0070] Exhaust gas recirculation (EGR) can have a parasitic effect on the engine system, that is, it reduces the effective power output of the engine system due to the energy required to move exhaust gases from the exhaust manifold into the intake manifold. This is particularly problematic on supercharged aspirated engines where intake manifold pressure may be higher than exhaust manifold pressure. Ironically, EGR is most needed when intake manifold pressure is high, such as when the engine is running under high load. In the case of turbocharged engines, increased back pressure in the exhaust manifold can also lead to knocking under high load.

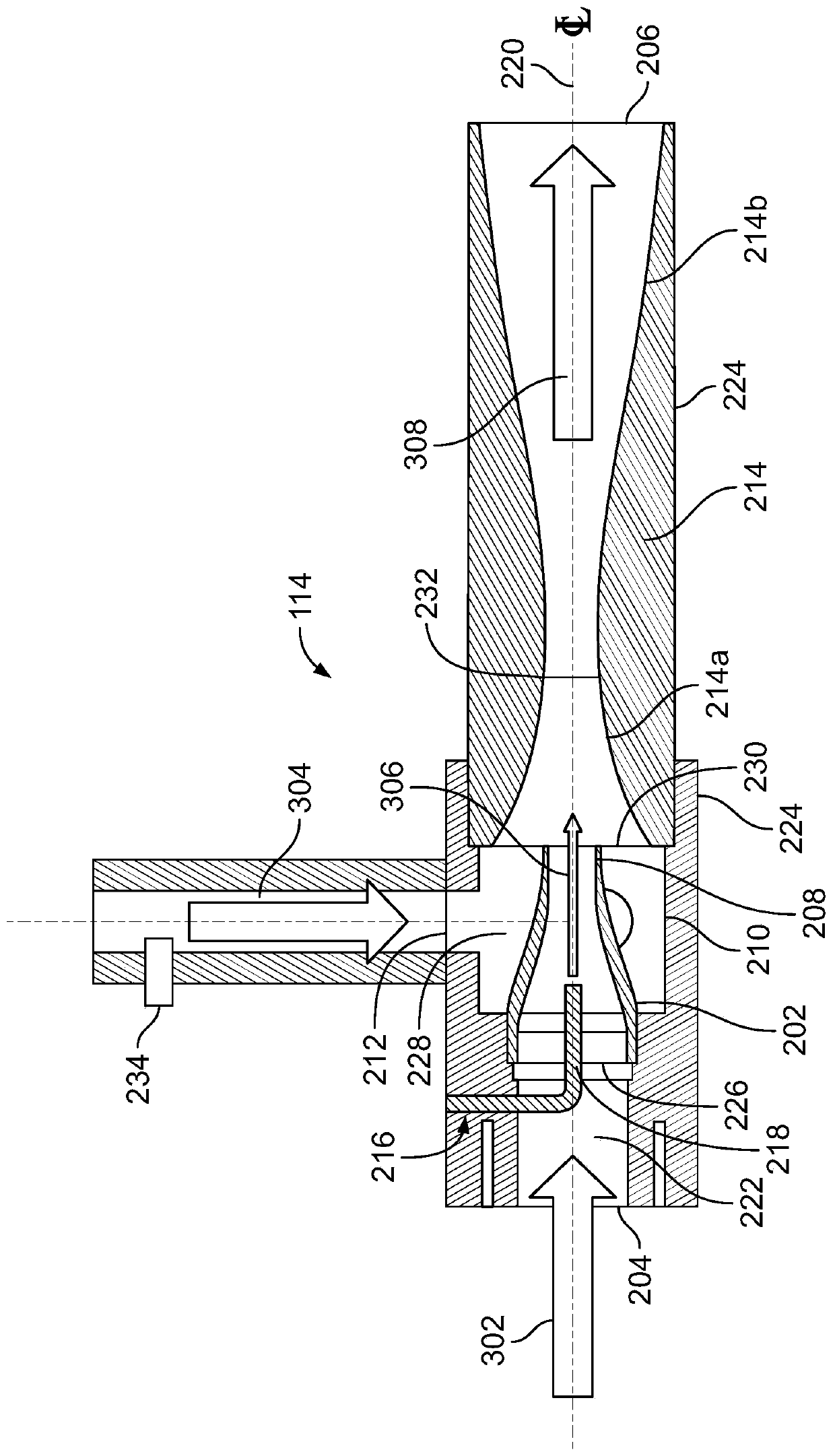

[0071] The concepts here relate to EGR systems that can be used in internal combustion engines, including supercharged induction internal combustion engines. An injection pump is added to the engine intake system between the throttle valve and the intake manifold. If a compressor is provided in the intake system, the jet pump may be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com