Isolated type fire extinguishing system for underground coal mine

A fire extinguishing system and mine technology, applied in mining equipment, fire prevention, fire rescue, etc., can solve problems such as the inability to meet the installation and maintenance requirements of electronic fire extinguishers and alarms, the narrow terrain of the mine, and the unsafety of non-mining professionals. The effect of avoiding the rapid spread of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

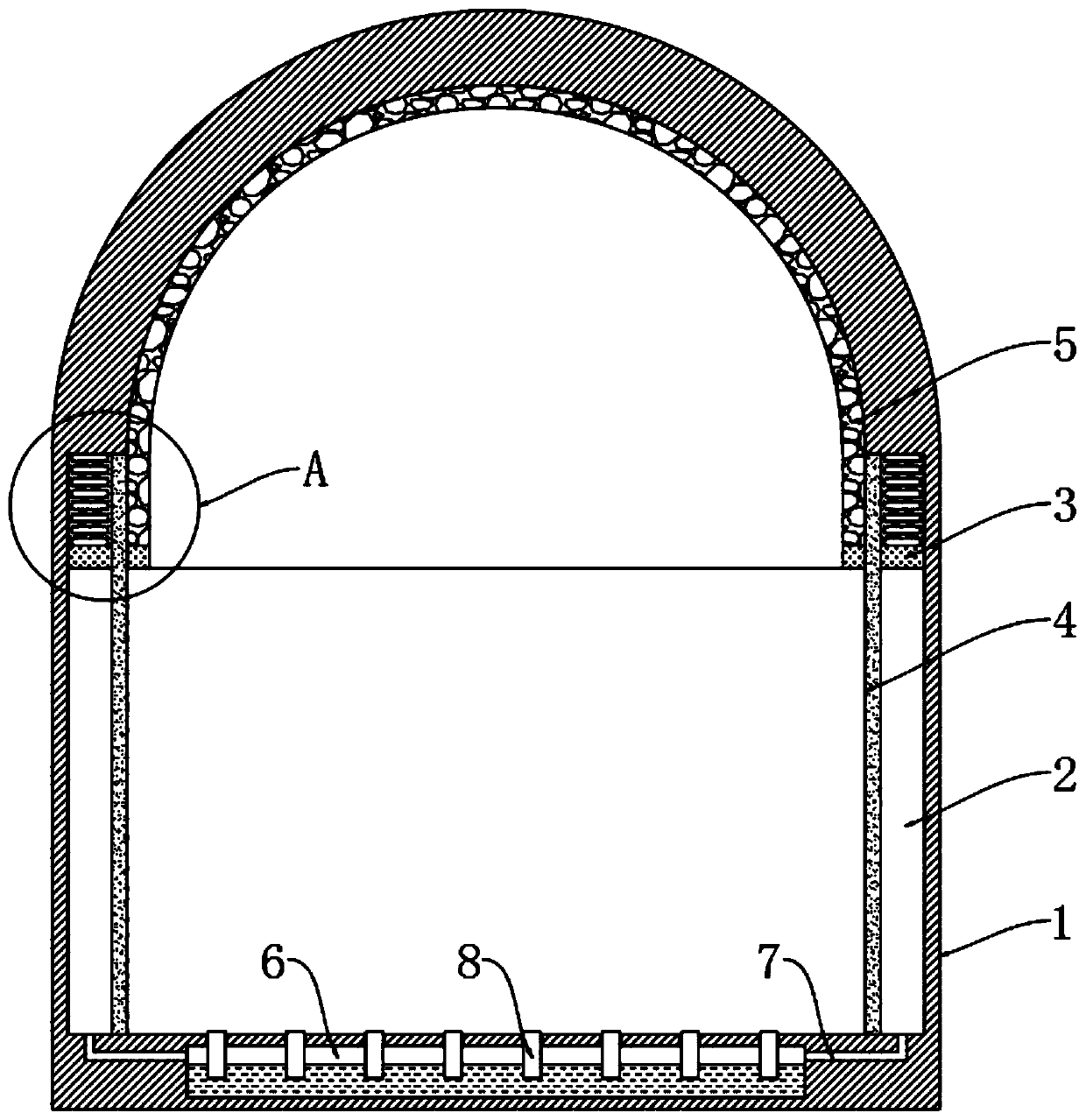

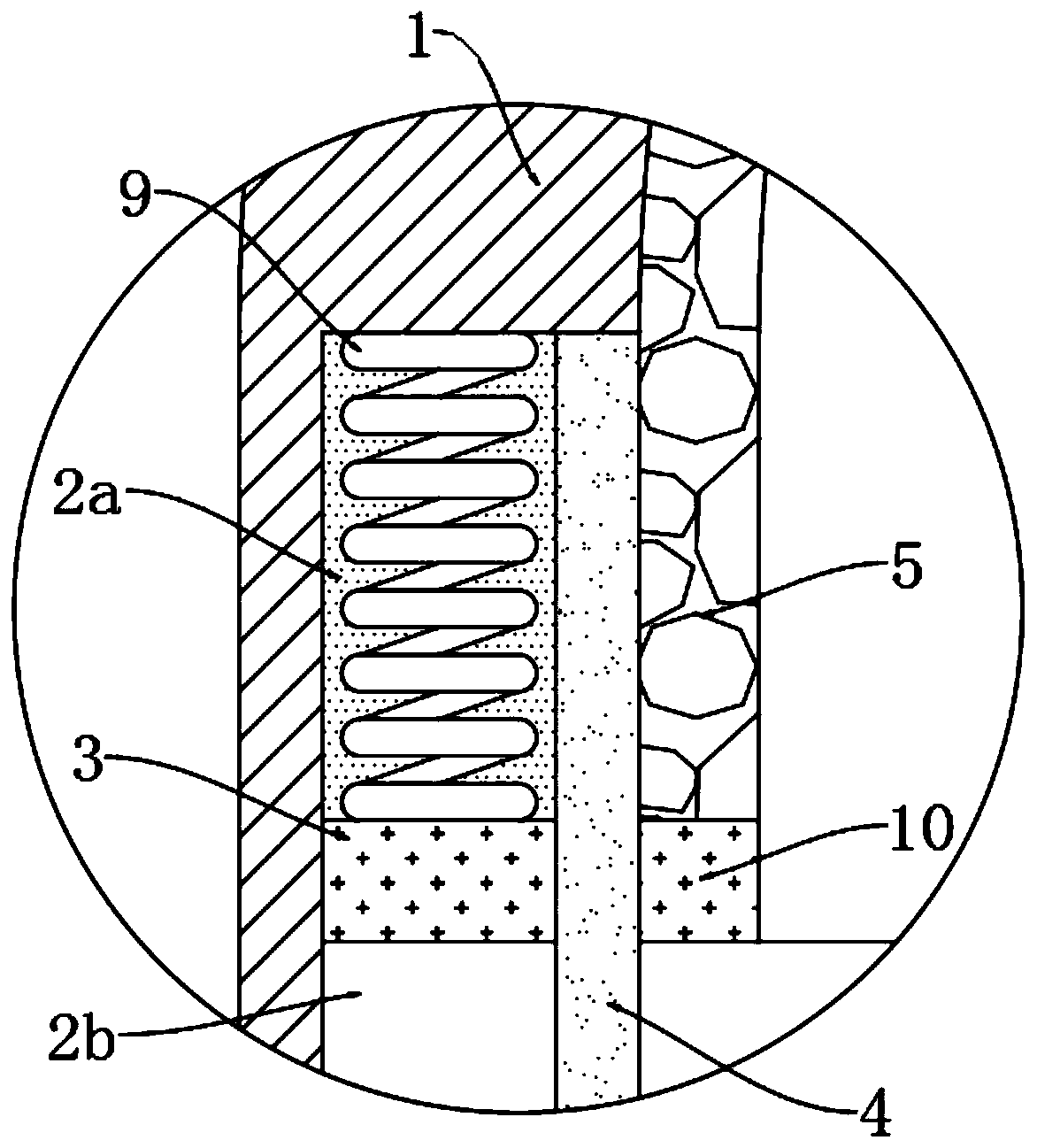

[0023] refer to Figure 1-3 , an isolated fire extinguishing system for underground coal mines, comprising a mine 1, a sliding chamber 2 is opened in the inner walls of both ends of the mine 1, and a first magnetic block 3 is sealed and slidably connected in the sliding chamber 2, and the first magnetic block 3 passes through a spring 9 is elastically connected to the top of the sliding chamber 2, and the first magnetic block 3 divides the sliding chamber 2 into an upper chamber 2a and a lower chamber 2b, the upper chamber 2a is filled with evaporating liquid, and the inner wall of the mine 1 is embedded with a heat conduction plate 4, The upper end of the heat conduction plate 4 is in contact with the evaporating liquid. A semi-cylindrical sealing cover 5 is arranged on the top of the mine 1. The lower ends of the two side walls of the sealing cover 5 are fixedly connected with a second magnetic block 10. The second magnetic block 10 is connected to the second magnetic block 1...

Embodiment 2

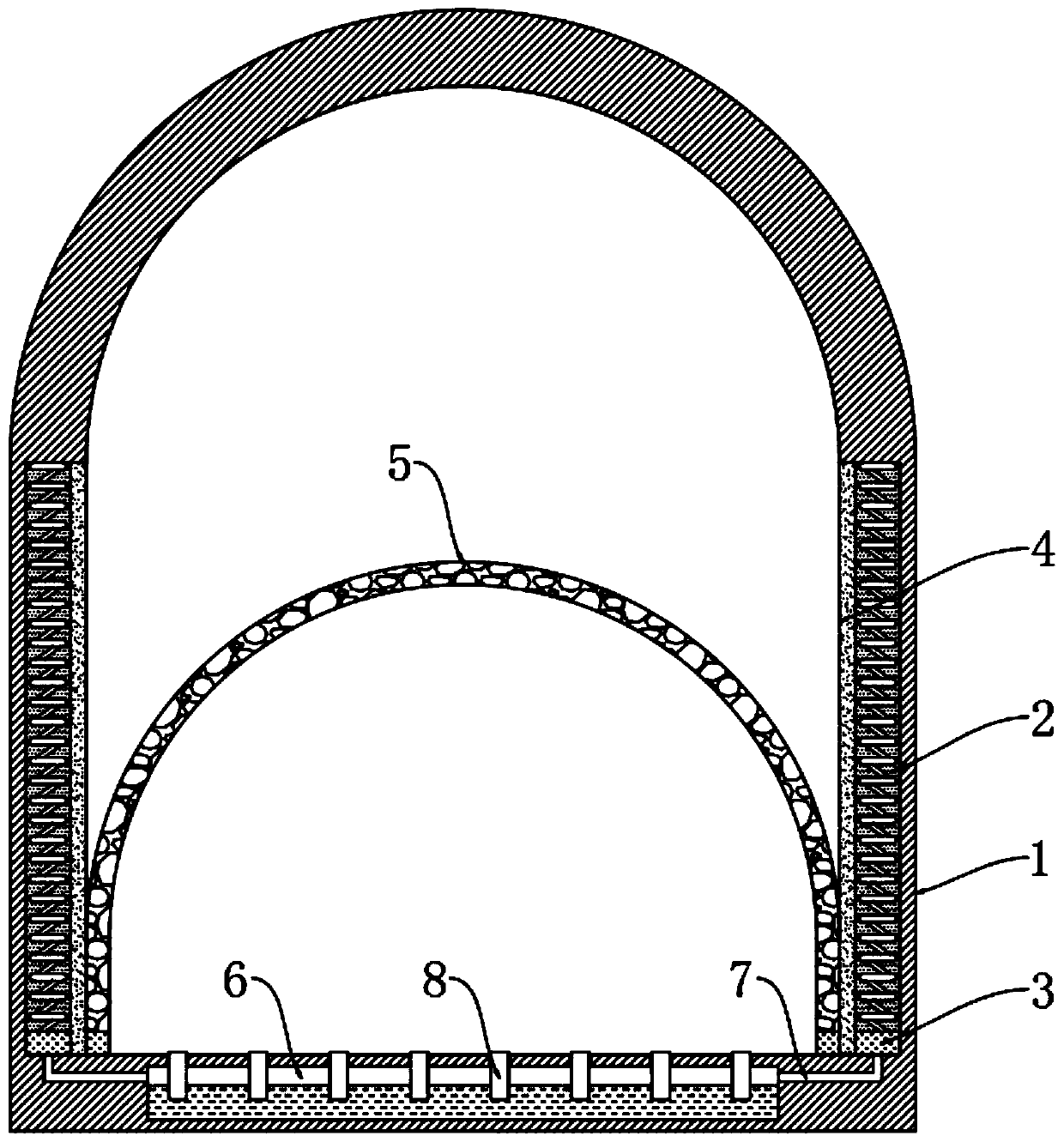

[0031] refer to Figure 4-6 The difference from the embodiment is that a device chamber 11 is provided in the wall of the sealing cover 5, and one end of the side wall of the device chamber 11 is fixedly connected with a telescopic air bag 12, and the telescopic air bag 12 is connected with the other end of the device chamber 11 through a memory metal sheet 13 The lower end of the sealing cover 5 is provided with an air inlet 14 communicating with the telescopic air bag 12 .

[0032] It should be noted that the memory metal sheet 13 is made into a folded shape at a high temperature, and stretched into an arc-shaped strip at a normal temperature state. Therefore, when the temperature in the mine 1 is normal temperature, the memory metal sheet 13 is an arc-shaped strip. The telescopic airbag 12 is in a normal state, and when the memory metal sheet 13 reaches the transformation temperature, its crystal structure changes and returns to a folded shape, thereby stretching the telesc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com