Woodworking machine

A technology of woodworking machines and racks, which is applied to wood processing equipment, manufacturing tools, forming/shaping machines, etc., can solve the problems of poor positioning stability and achieve high positioning stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

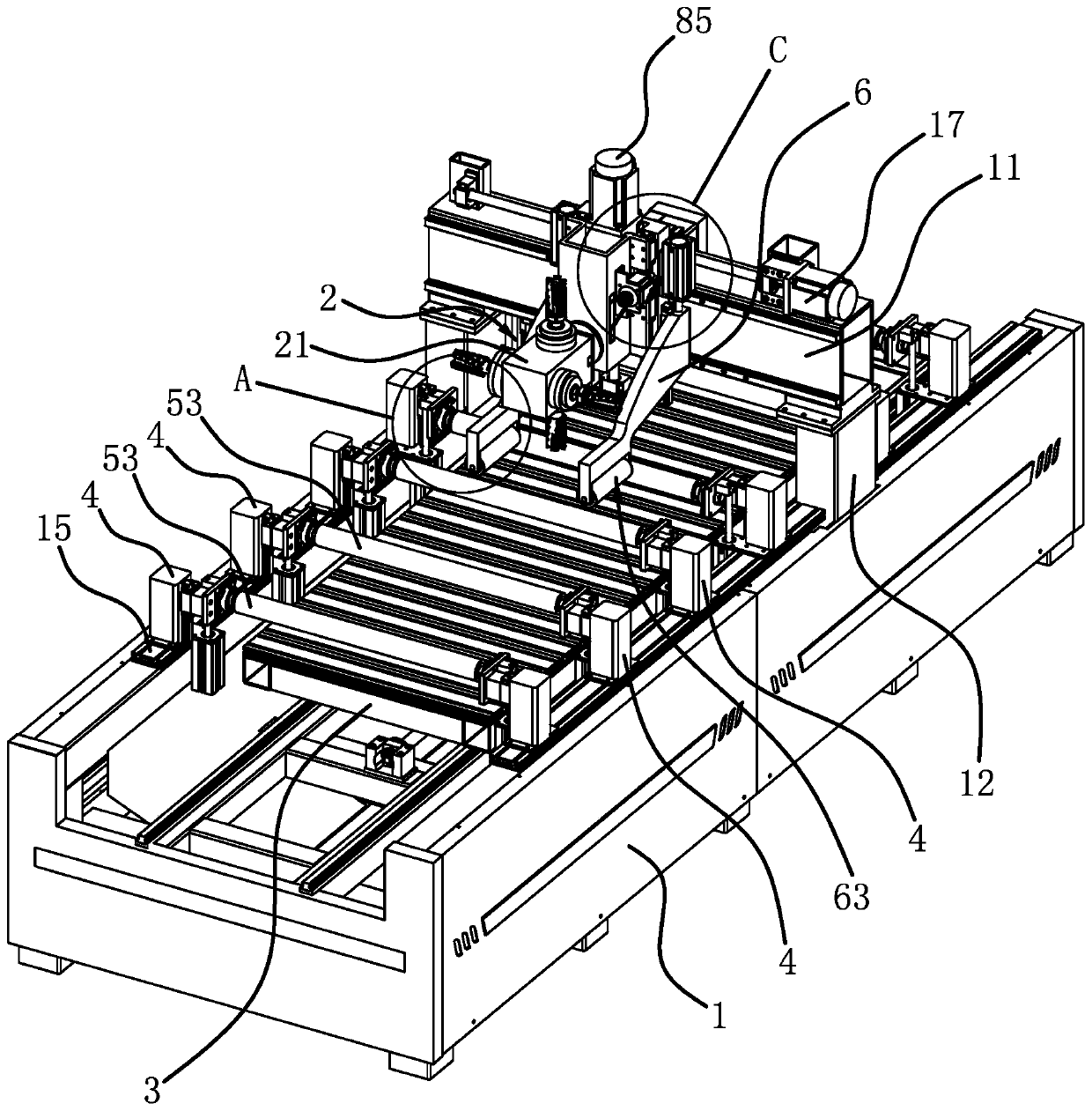

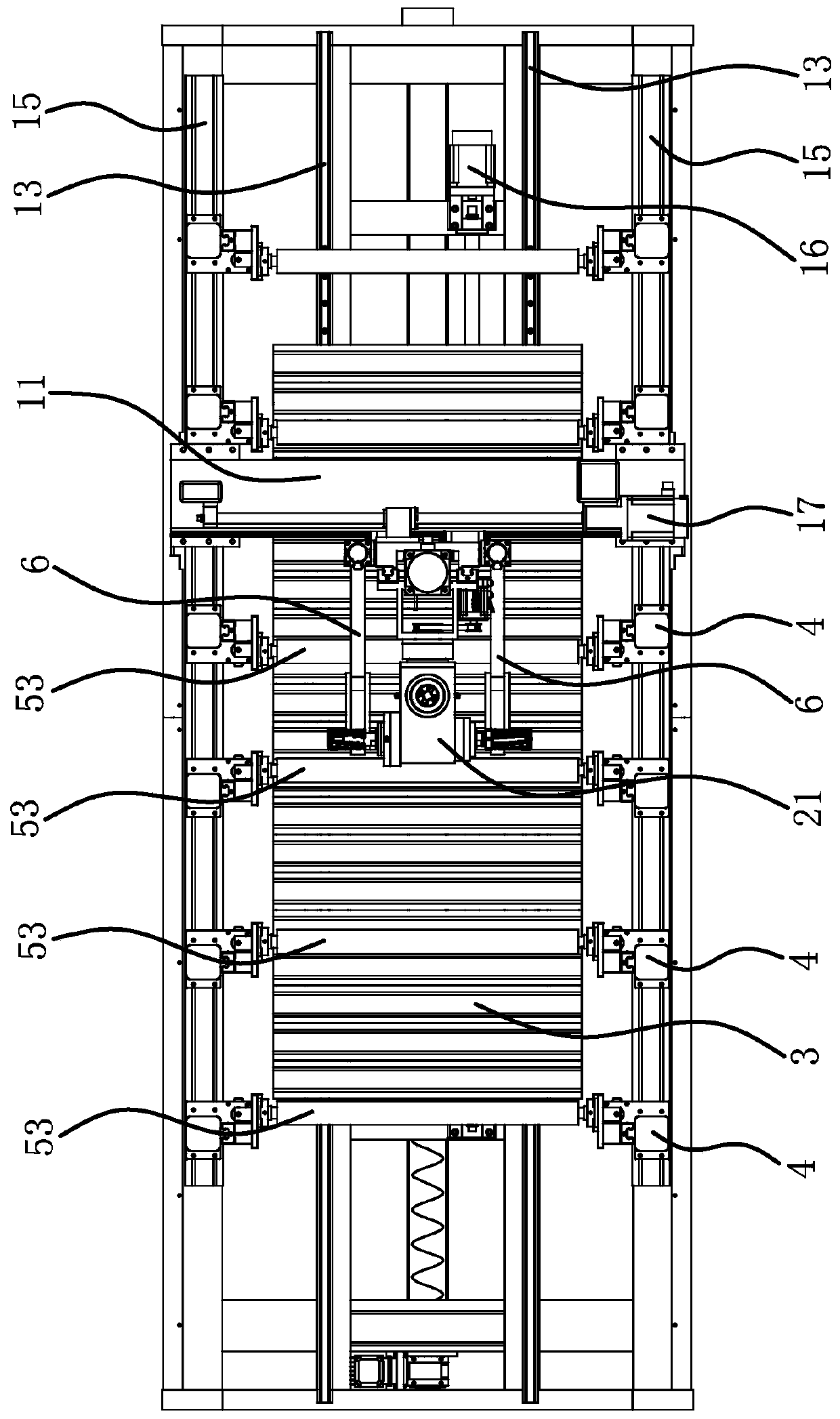

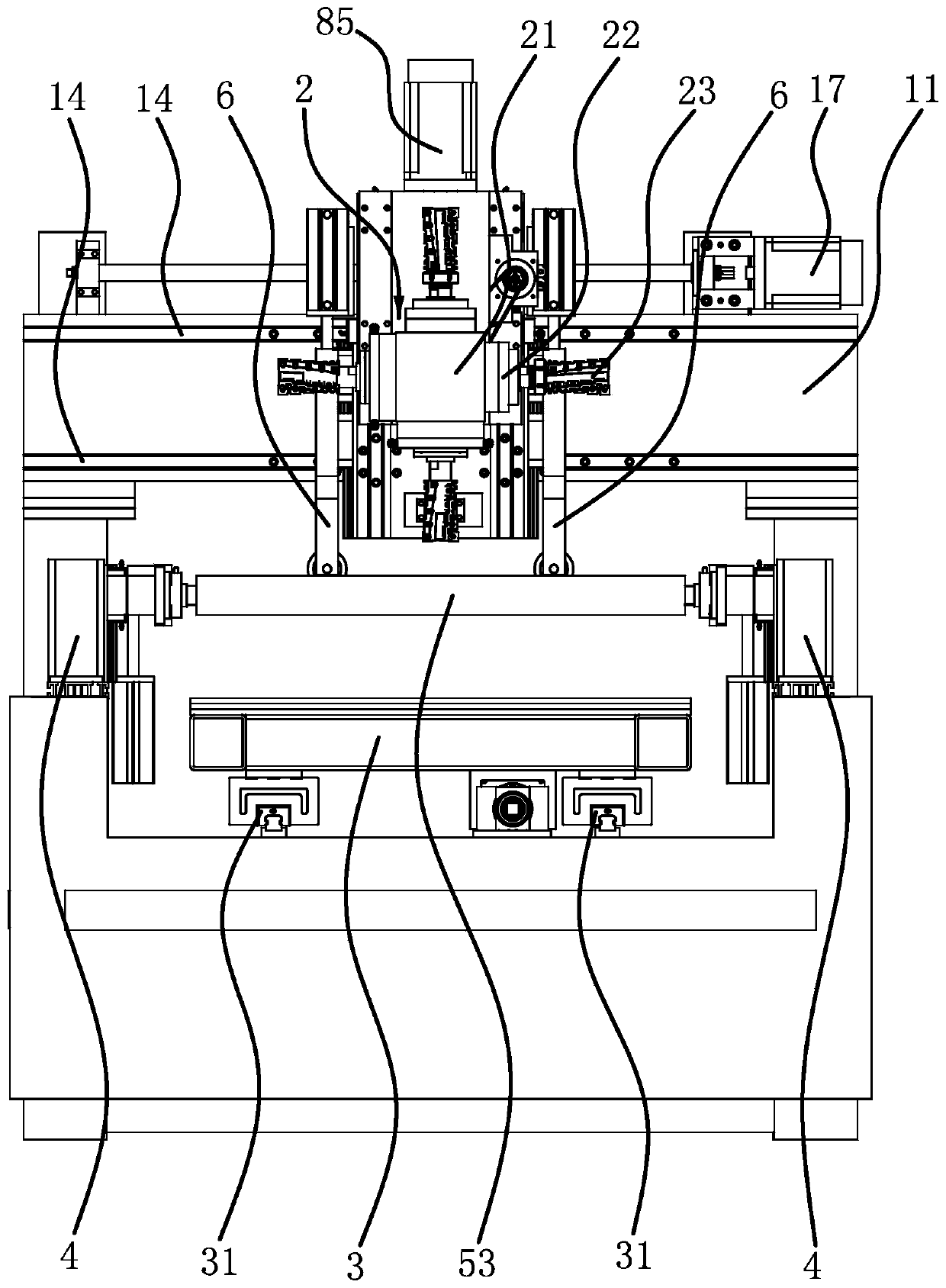

Embodiment 1

[0038] Such as Figure 1 to Figure 4 As shown, the woodworking machine includes a frame 1 and a cross beam 11. Vertical columns 12 are vertically fixed at the two sides of the frame 1 approximately in the middle of the longitudinal direction. The cross beam 11 is arranged in the transverse direction, and the two ends of the cross beam 11 are respectively fixed on the two columns. At the top of 12, a horizontal carriage 8 is slidably connected to one side of the cross beam 11 in a horizontal direction, a vertical carriage 9 is slidably connected to the side of the horizontal carriage 8 in a vertical direction, and a processing component is connected to the vertical carriage 9 2. The movement of the horizontal carriage 8 and the vertical carriage 9 realizes the horizontal and vertical movement of the processing assembly 2, and a processing platform 3 is slidably connected to the frame 1 along the longitudinal direction. The processing platform 3 is arranged horizontally, and its u...

Embodiment 2

[0043] The structure of the woodworking machine is basically the same as that of the first embodiment, the difference lies in Picture 9 , Picture 10 As shown, a guide sleeve 64 is provided in the connecting hole 621 of the positioning frame 6. The guide sleeve 64 includes a cylindrical holder 641. The holder 641 is uniformly distributed with through holes, and the through holes are provided with balls 642 and a longitudinal pressing roller 63 The connecting posts 631 at both ends are respectively penetrated in the two cages 641 and abut on the balls 642. The axial length of the longitudinal pressing roller 63 is smaller than the distance between the two connecting protrusions 62, and the connecting posts 631 are also sleeved A return spring 65, one end of the return spring 65 abuts against the end surface of the longitudinal pressing roller 63, and the other end abuts against the connecting protrusion 62, when the longitudinal pressing roller 63 is pressed against the workpiece...

Embodiment 3

[0045] The structure of the woodworking machine is basically the same as that of the first embodiment, the difference lies in Picture 11 , Picture 12 As shown, the longitudinal pressing roller 63 has a tubular shape. A connecting column 631 is fixed between the two connecting protrusions 62. The connecting column 631 is arranged in the longitudinal direction. The longitudinal pressing roller 63 is sleeved on the connecting column 631. The inner diameter of the longitudinal pressing roller 63 is larger than The outer diameter of the connecting column 631 is provided with a guide sleeve 64 at both ends of the longitudinal pressing roller 63. The guide sleeve 64 includes a cylindrical holder 641 which is sleeved on the connecting column 631. The holders 641 are both The through holes are arranged with balls 642. The inner side surface of the longitudinal pressing roller 63 and the outer side surface of the connecting post 631 abut on the balls 642, so that the longitudinal pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com