Transverse moving rotating wheel funnel device

A funnel and traverse technology, which is used in transportation and packaging, transportation of filamentous materials, and processing of thin materials, can solve the problems of high cost, inability to promote, and low labor efficiency, and achieve convenient control, simple structure, and effective guarantee. input effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] Such as Figure 1-7 Shown, the present invention is a kind of traversing wheel funnel device.

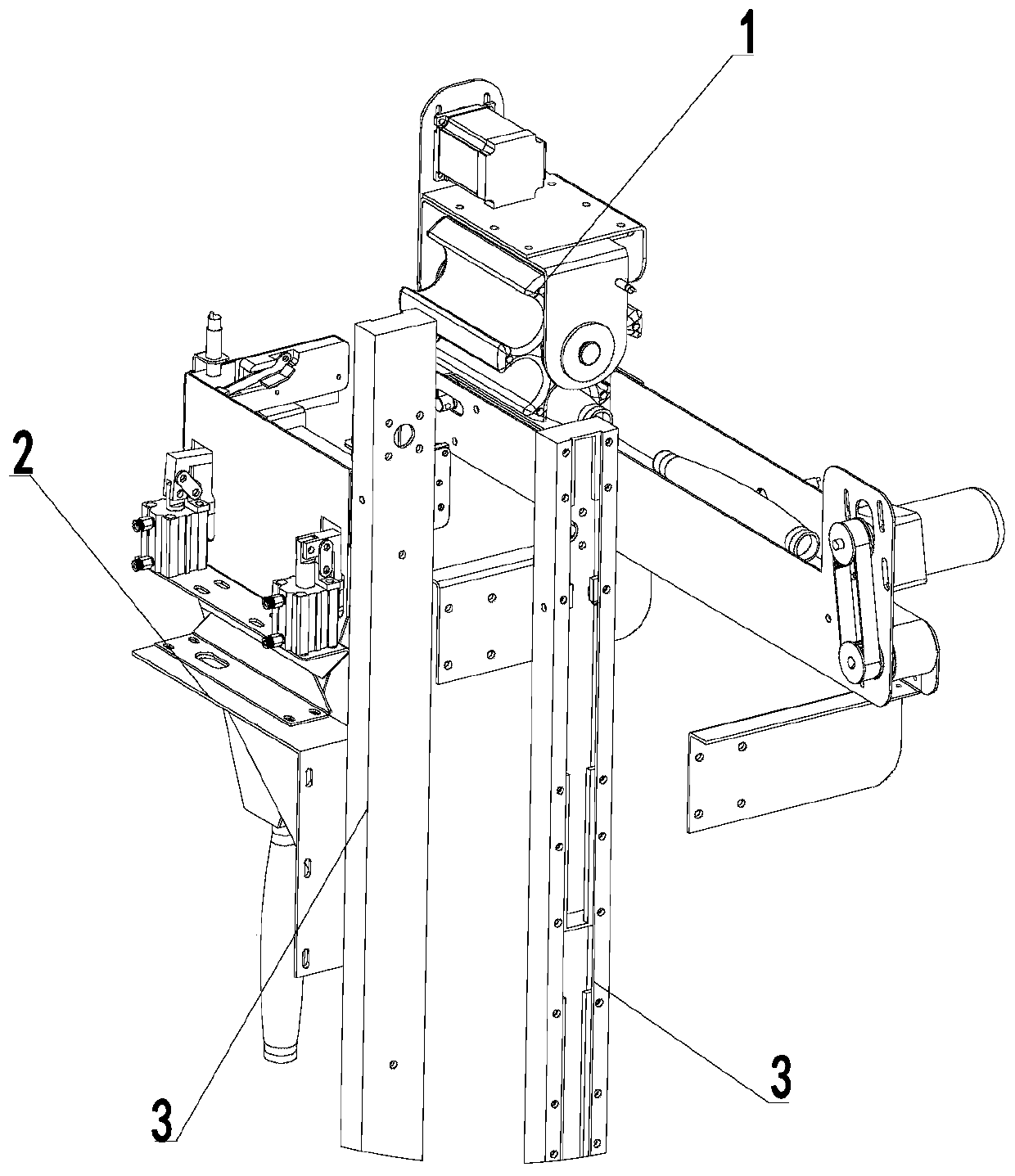

[0022] The traversing runner funnel device described in this embodiment includes a lifting column welding part 3, the entrance traversing conveyor 1 is fixedly installed on the left and right lifting column welding parts 3, and the turning table funnel part 2 is installed on a single lifting column for welding On part 3, the outlet of the inlet traverse conveyor 1 is located at the inlet of the turning table funnel part 2.

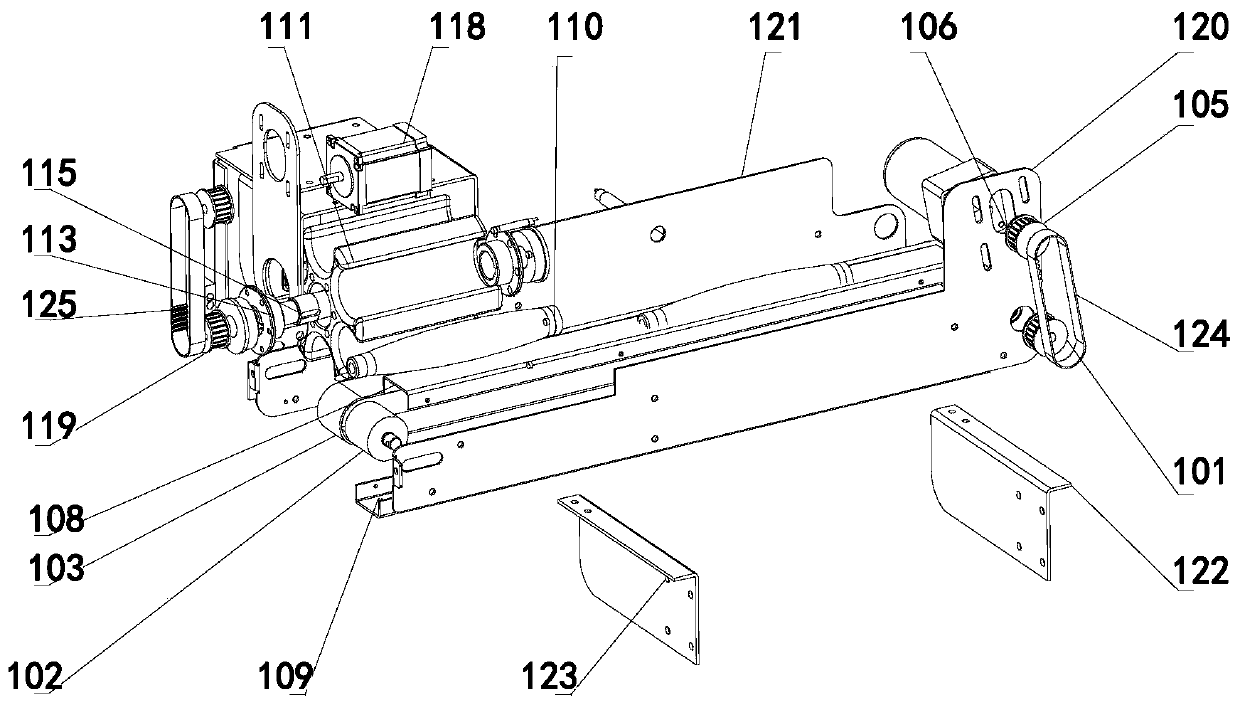

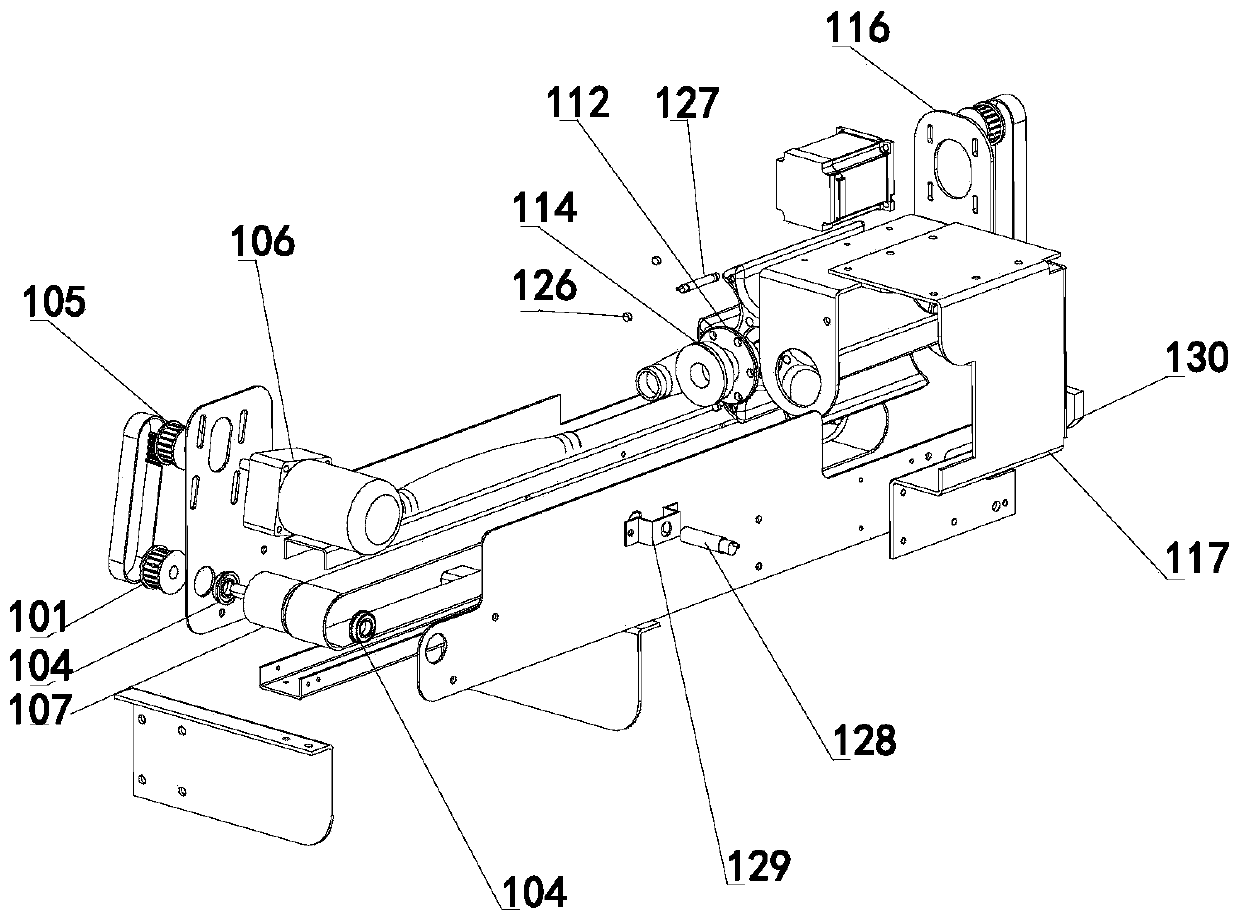

[0023] The entrance traversing conveyor 1 includes a lower supporting plate 109 of the motor plate, and the two sides of the lower supporting plate 109 of the motor plate are provided with side plates 121 and right 120 of the lateral moving conveyor belt motor plate, and the upper part is provided with The conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com