Power supply circuit of electric sewing machine

A technology for electric sewing machines and power circuits, which is applied in the direction of high-efficiency power electronic conversion, electrical components, and adjustment of electric variables, etc., which can solve problems such as difficulty in using feet, increased power consumption of electric sewing machines, and increased use costs of electric sewing machines. Effects of power loss and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

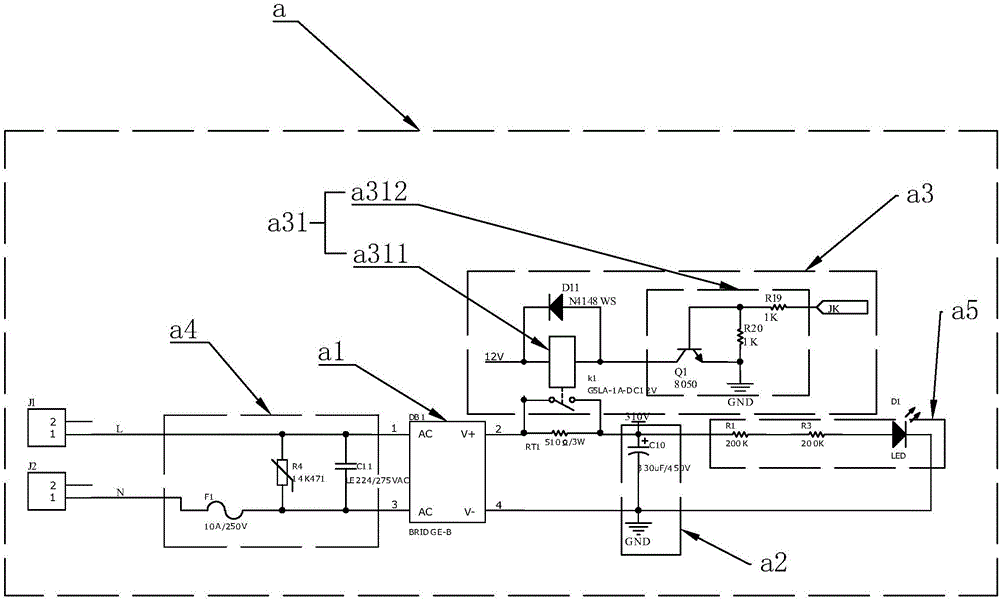

[0038] As an improved specific implementation manner, the short-circuit circuit a31 includes:

[0039] A short-circuit relay a311, the short-circuit relay a311 has a switch part and an electromagnetic part, the switch part is connected in parallel with the anti-shock resistance RT1, and the electromagnetic part controls the opening and closing of the switch part;

[0040] A driving circuit a312, the driving circuit a312 is coupled to the short-circuit relay a311 to provide an action signal to the electromagnetic part of the short-circuit relay a311, and the driving circuit a312 includes:

[0041]Switching transistor Q1, the base of the switching transistor Q1 is coupled with a resistor and then coupled to the control chip of the driver, the emitter is grounded, the emitter is also coupled with a resistor and then coupled to the base, and the collector is coupled to the short circuit relay a311 The electromagnetic part is then coupled to the power supply. Through the setting of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com