A kind of production method of flat cut paper

A production method and flat cutting technology, which is applied in the direction of folding thin materials, thin material processing, machining/deformation, etc., can solve the problems of troublesome use and placement, and achieve the effects of simple placement, reduced space occupation, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

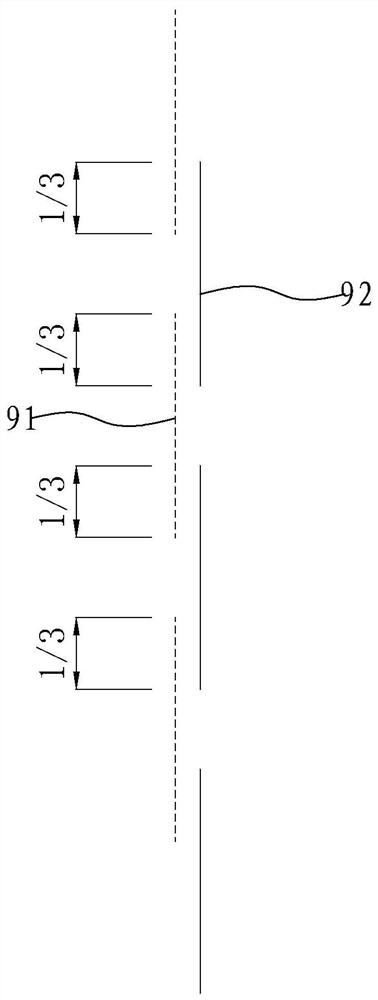

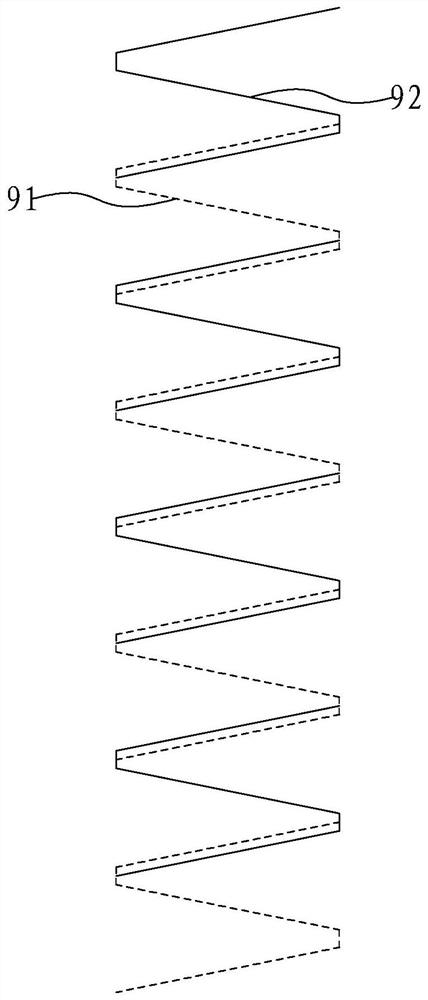

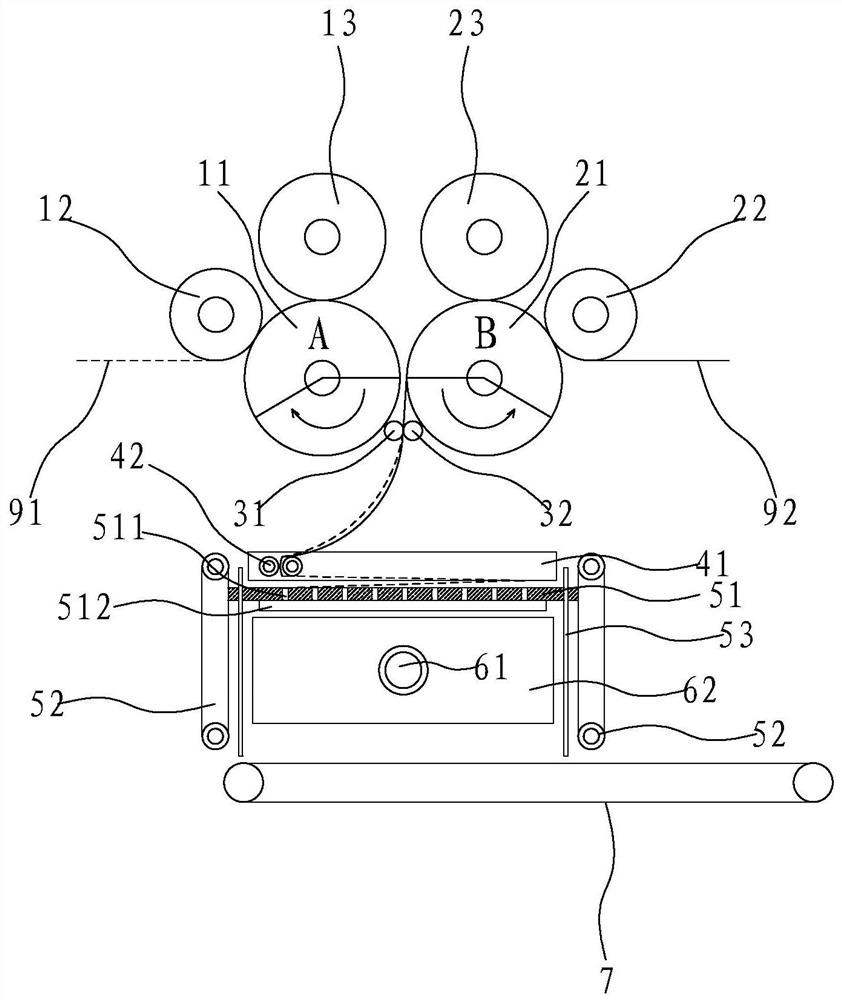

[0031] refer to Figure 1 to Figure 6 , the present embodiment provides a packaging device for flat-cut paper, including a frame and a left roller mechanism for conveying the first flat-cut paper 91, and a left roller mechanism for conveying the second flat-cut paper 92. The right rolling mechanism, the embossing roller group, the guide roller mechanism, the receiving device, the pushing device, and the output conveyor belt 7, the left rolling mechanism includes a left suction roller 11 rotatably arranged on the frame, a left pressing roller 12. The left cutter roller 13, the left pressure roller 12 and the left cutter roller 13 cooperate with the left suction roller 11 to rotate respectively, and the adsorption area of the left suction roller 11 is image 3 In the area A shown, the right rolling mechanism includes a right suction roller 21, a rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com