Phase-change aroma-releasing coating layer tipping paper and preparation method thereof

A technology of tipping paper and fragrance release, which is applied in wrapping paper, wrapping paper, packaging, etc., can solve problems such as oral smoke residue, and achieve the effects of guaranteed safety, improved comfort, increased production costs and technical difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

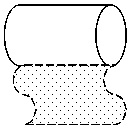

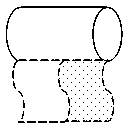

Image

Examples

Embodiment 1

[0026] A preparation method of phase-change fragrance-releasing coating tipping paper is as follows:

[0027] (1): Polyethylene glycol, food-grade paraffin, palm wax, and beeswax were heated, mixed and stirred at 45°C for 1 hour at a mass ratio of 1:0.5:0.1:0.5, and stored at 45±2°C to obtain a phase change material.

[0028] (2): The taste and smell materials, mint cooling agent, honey, and tangerine peel essence were mixed and stirred at 45°C for 30 minutes at a mass ratio of 1:1:0.5 to obtain aroma substances.

[0029] (3): Mix and stir the phase change material prepared in step (1) and the fragrance substance prepared in step (2) at a mass ratio of 1:15 at 45°C to obtain a fragrant phase change material with a melting point controlled at 45°C ℃.

[0030] (4): Uniformly print the scented phase-change material prepared in step (3) on the base paper of the tipping paper through a single-sided printing process, and the coating amount is 2g / ㎡.

[0031] (5): The drying tempera...

Embodiment 2

[0034] A preparation method of phase-change fragrance-releasing coating tipping paper is as follows:

[0035] (1): Compound polyethylene glycol and food-grade paraffin in a mass ratio of 3:1, heat and stir at 60°C for 1 hour to prepare a phase change material.

[0036] (2): Use mint cooling agent and honey for taste, and tangerine peel essence for smelling, which are mixed according to the mass ratio of mint cooling agent: honey: tangerine peel essence in a mass ratio of 1:3:1; stir at 30°C for 1 hour to prepare fragrance substances.

[0037] (3): Compound the phase change material prepared in step (1) and the flavor substance prepared in step (2) at a mass ratio of 1:10 to obtain a phase change material with a fragrance, and the melting point is controlled at 45°C.

[0038] (4): The scented phase change material prepared in step (3) is printed on the base paper of tipping paper with 1 / 2 part of one side, and the coating amount is 2.5g / ㎡.

[0039] (5): The drying temperature ...

Embodiment 3

[0042] A preparation method of phase-change fragrance-releasing coating tipping paper is as follows:

[0043] (1): Food-grade paraffin wax, palm wax, and beeswax were compounded according to the mass ratio of 1:0.5:2, heated and stirred at 70°C for 1 hour, and the phase change material was prepared.

[0044] (2): The mint cooling agent, honey, and tangerine peel are dissolved in a mass ratio of 1.5:1:1. Stir at 30 °C for 1 h to prepare the aroma substance.

[0045] (3): The phase change material prepared in step (1) and the fragrance substance prepared in step (2) were compounded at a mass ratio of 5:6 to obtain a phase change material with fragrance, and its melting point was controlled at 70°C.

[0046] (4): The scented phase change material prepared in step (3) is applied to the base paper of the tipping paper on both sides through the coating process, and the coating amount is 1g / ㎡.

[0047] (5): The drying temperature of the coating process is 32°C.

[0048] (6): Seale...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com