Device and method for measuring inward expansion deformation rate of three-dimensional coal matrix

A measurement device, coal matrix technology, applied in the direction of measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve problems such as the influence of the accuracy of theoretical model permeability data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0137] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

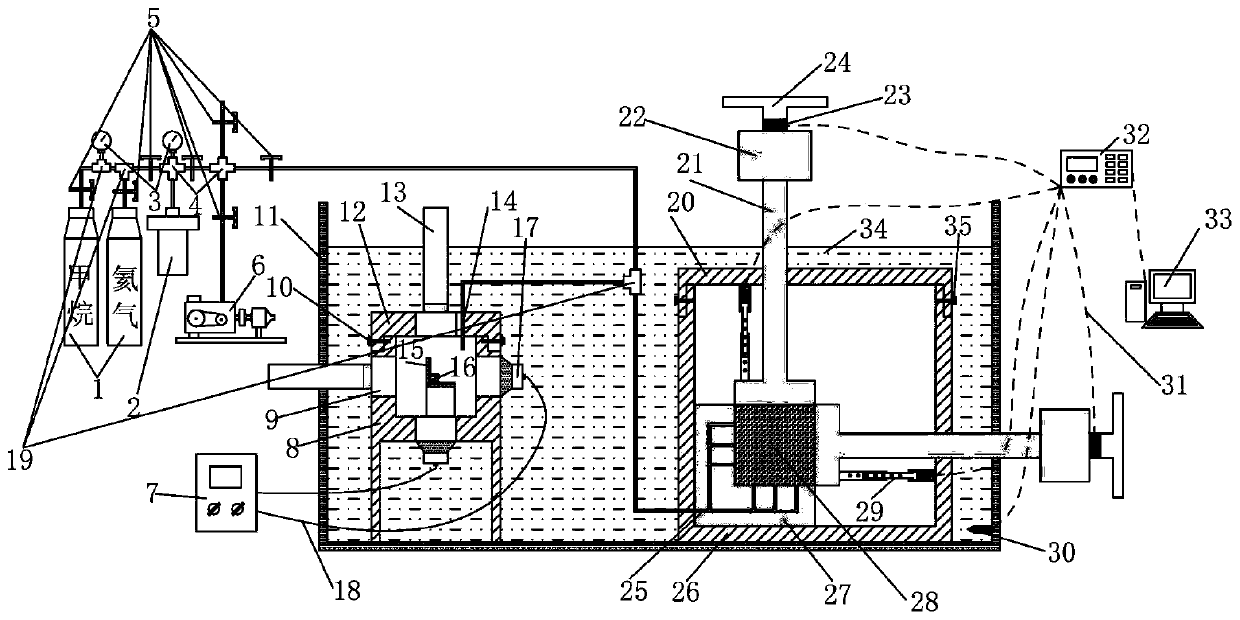

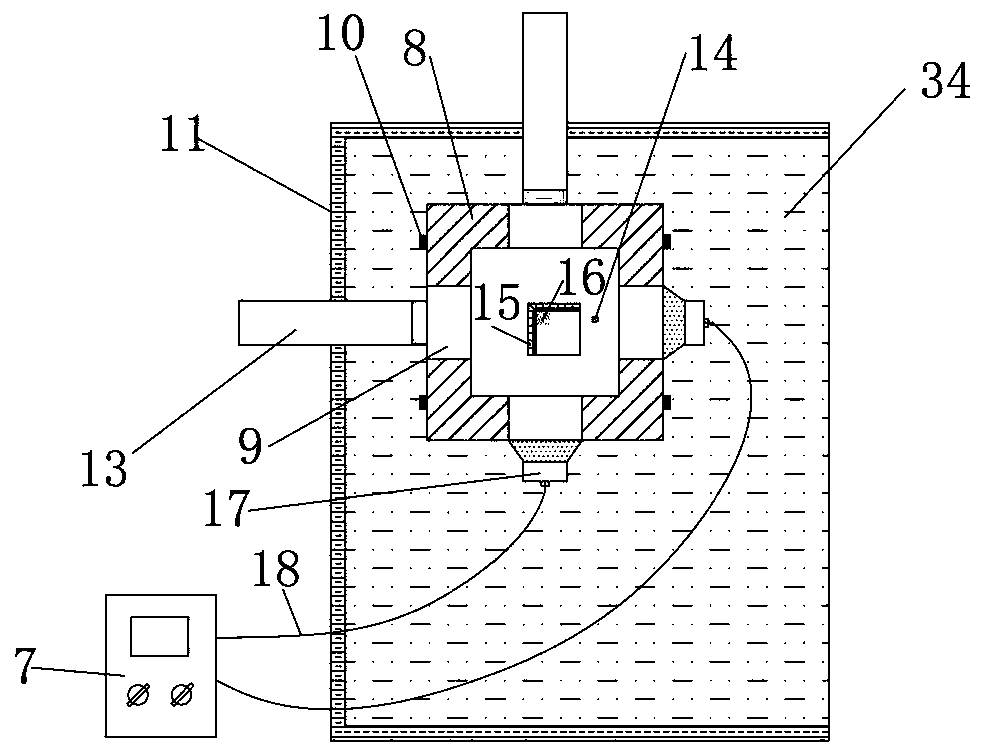

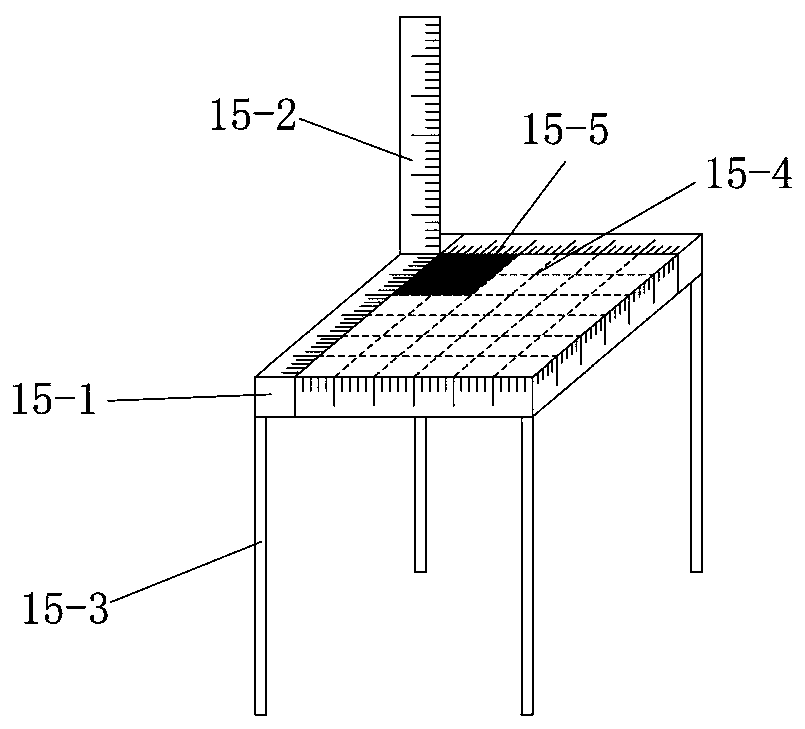

[0138] like Figure 1-8 As shown, the measurement device includes a gas system, a coal matrix deformation measurement system, a coal deformation measurement system, a data acquisition system and a constant temperature water bath system. The gas path system includes a gas cylinder 1, a gas storage tank 2, a pressure gauge 3, a four-way valve 4, a valve 5, a vacuum pump 6, an air inlet pipe 14 of a coal matrix deformation measuring device, a three-way valve 19 and a coal body deformation measuring device Intake pipe 25. The coal matrix deformation measurement system includes a light source control cabinet 7, a coal matrix deformation measurement device shell 8, a high-strength glass 9, a sealing bolt 10, a coal matrix deformation measurement device upper cover 12, a microscope 13, and a coal matrix deformation measurement platform 15 , coal matrix 16, light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com