Uncertainty system PID controller design method based on time-varying reliability

A technique of uncertainty, design methods, applied in the direction of controllers with specific characteristics, electric controllers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

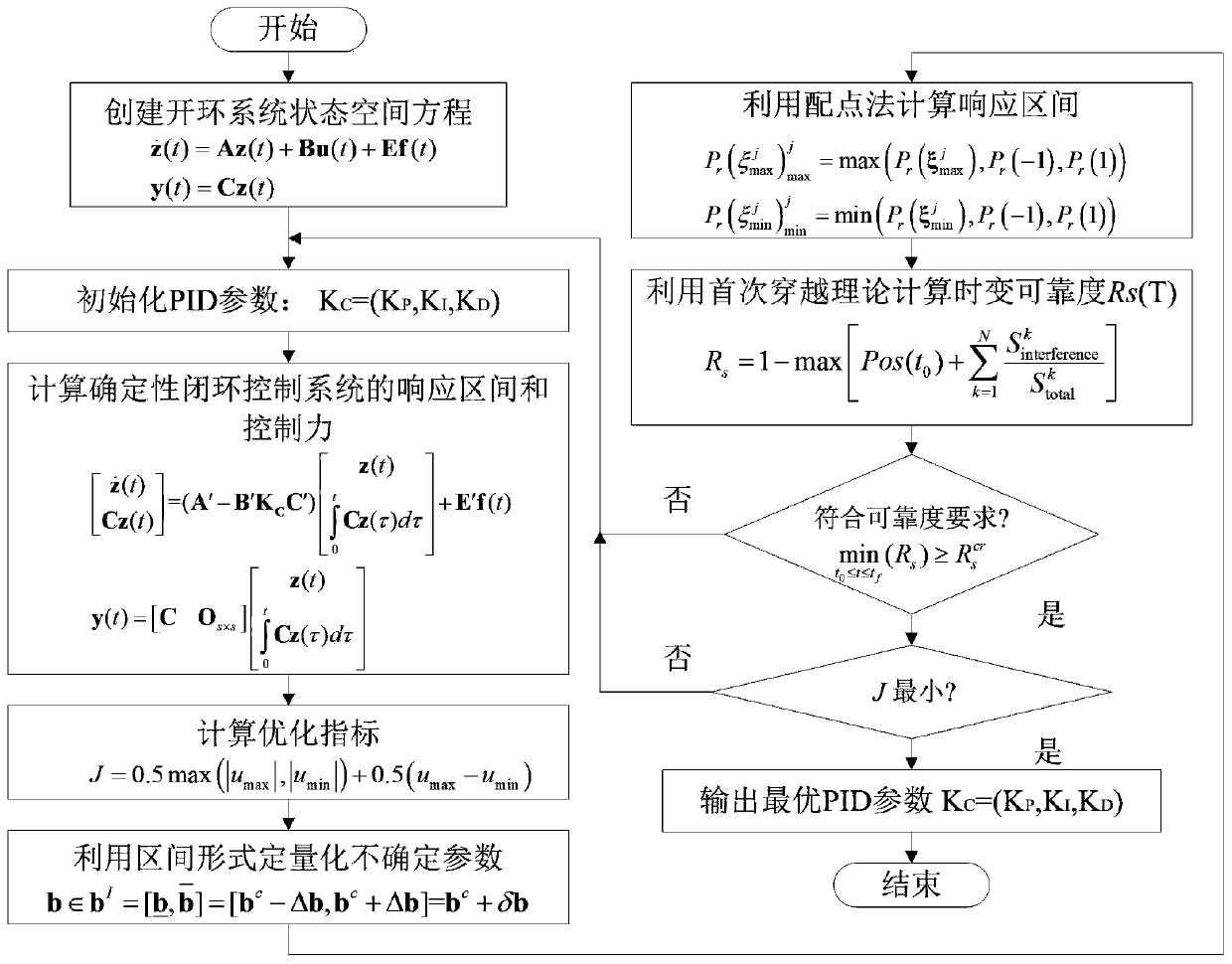

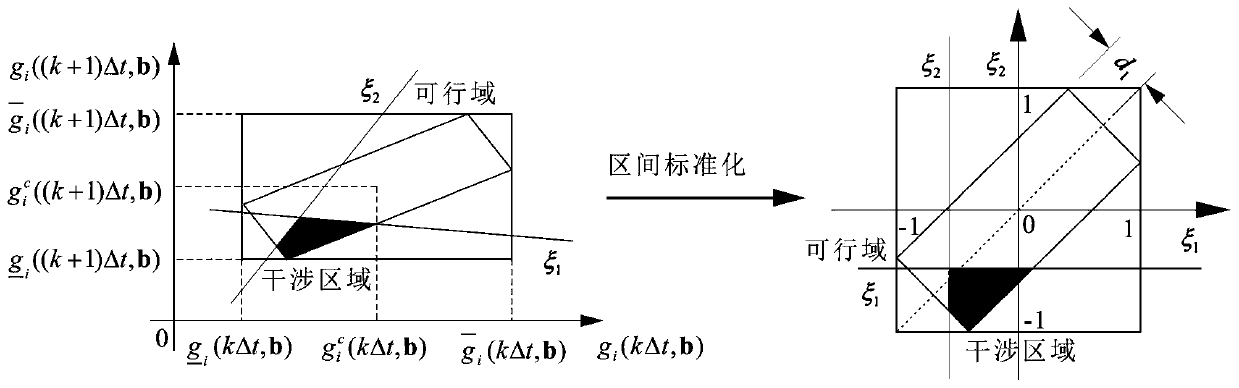

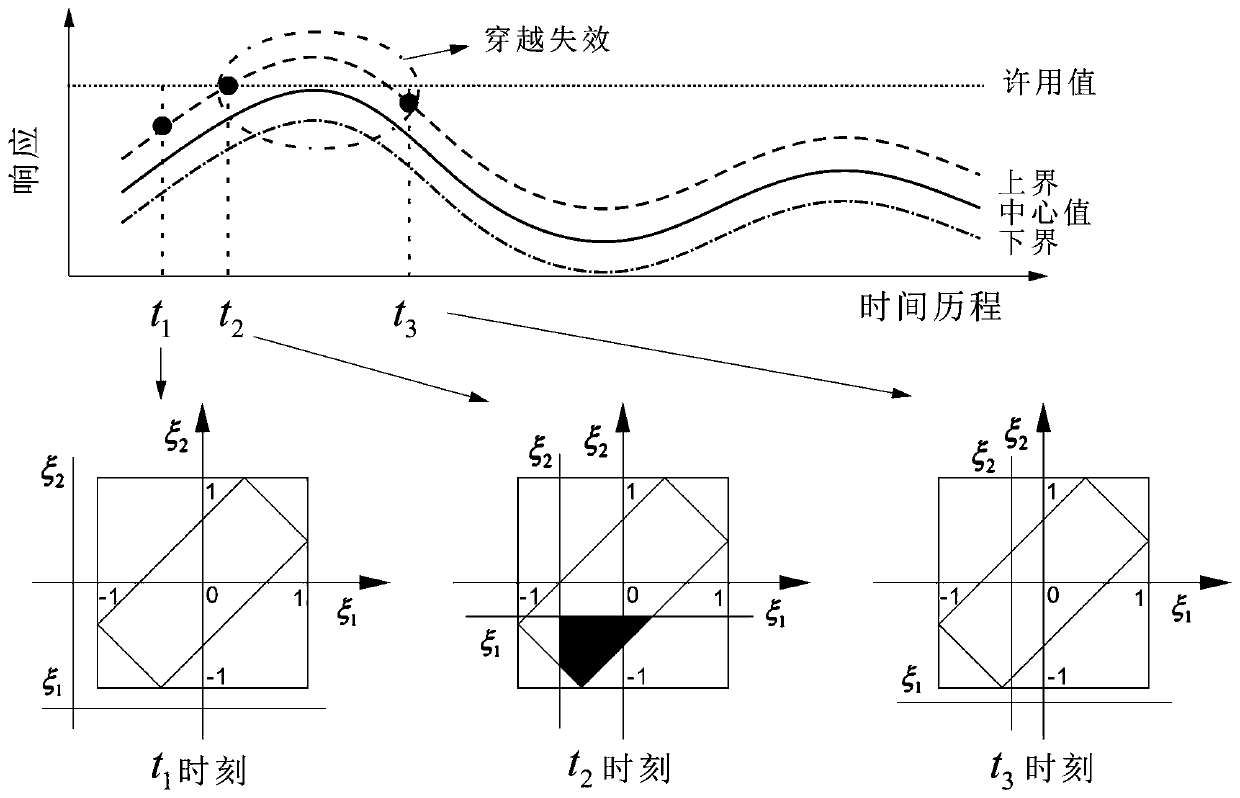

Method used

Image

Examples

Embodiment 1

[0165] Such as Figure 4 As shown, the 10-DOF mass-spring-damper system only has the translational DOF ux in the horizontal direction, the mass of each mass m=1kg, the spring stiffness k=1000N / m, and the damping c=5N / ms -1 . Applied on the proof mass 10 Figure 5 (a) shows a horizontal pulse load f(t) with an amplitude of 10kN, and a control force u(t) is exerted on the mass block 7 . Both the mass m and the stiffness k have 5% uncertainty, and the horizontal displacement response of the mass 10 is assumed to be x(t).

[0166] system at t 0 = The open-loop response after 1.3s is as follows Figure 5 As shown in (b), the displacement design requirement of mass block 7 is at t 0 After = 1.3s, the absolute value of the displacement does not exceed x cr = 0.02m. In order to compare the controller design based on time-varying reliability with the traditional H ∞ Robust controller design, consider the following three situations for controller design:

[0167] (1) The time-v...

Embodiment 2

[0181] Such as Figure 6 Shown is the solar panel structure in the actual project, and the four panels are all parallel to the xy plane. Among them, plates 1, 2, and 3 have been connected together, and the translation degrees of freedom in three directions are constrained on one side. Plate No. 4 is docked with Plate No. 2 along the z direction, and Plate No. 2 is subjected to disturbance loads such as Figure 7(a) shown. The sensor and actuator layout of the controller is arranged on the edge of the No. 2 board. The Rayleigh damping of the system is a definite value, but there are uncertainties in the density and stiffness. The design requirement is the z-direction displacement z(t) of the observation point at t 0 = No more than z after 1s cr = 1.5m and the time-varying reliability is not less than 0.95, that is Considering the symmetry of the structure and the controller, the PID parameters of the two controllers are the same, so in fact only need to design a set of K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com