Pressing element, assembly and electrical equipment

A technology of electrical devices and assemblies, which is applied in the direction of electrical components, electrical equipment structural parts, cooling/ventilation/heating transformation, etc., can solve the problems of complex assemblies, increase the height of assemblies, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

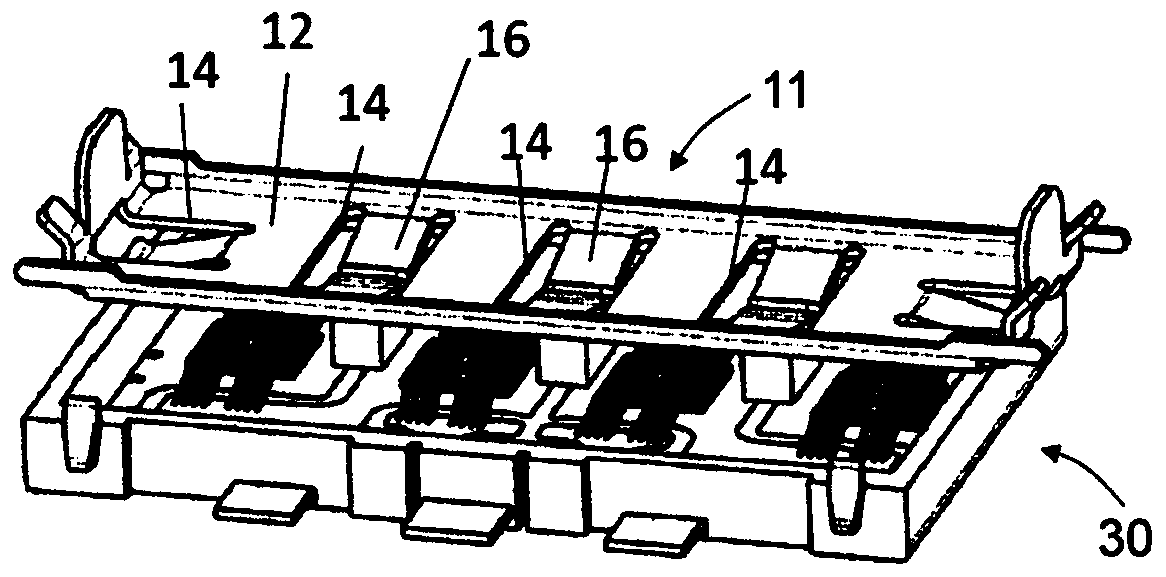

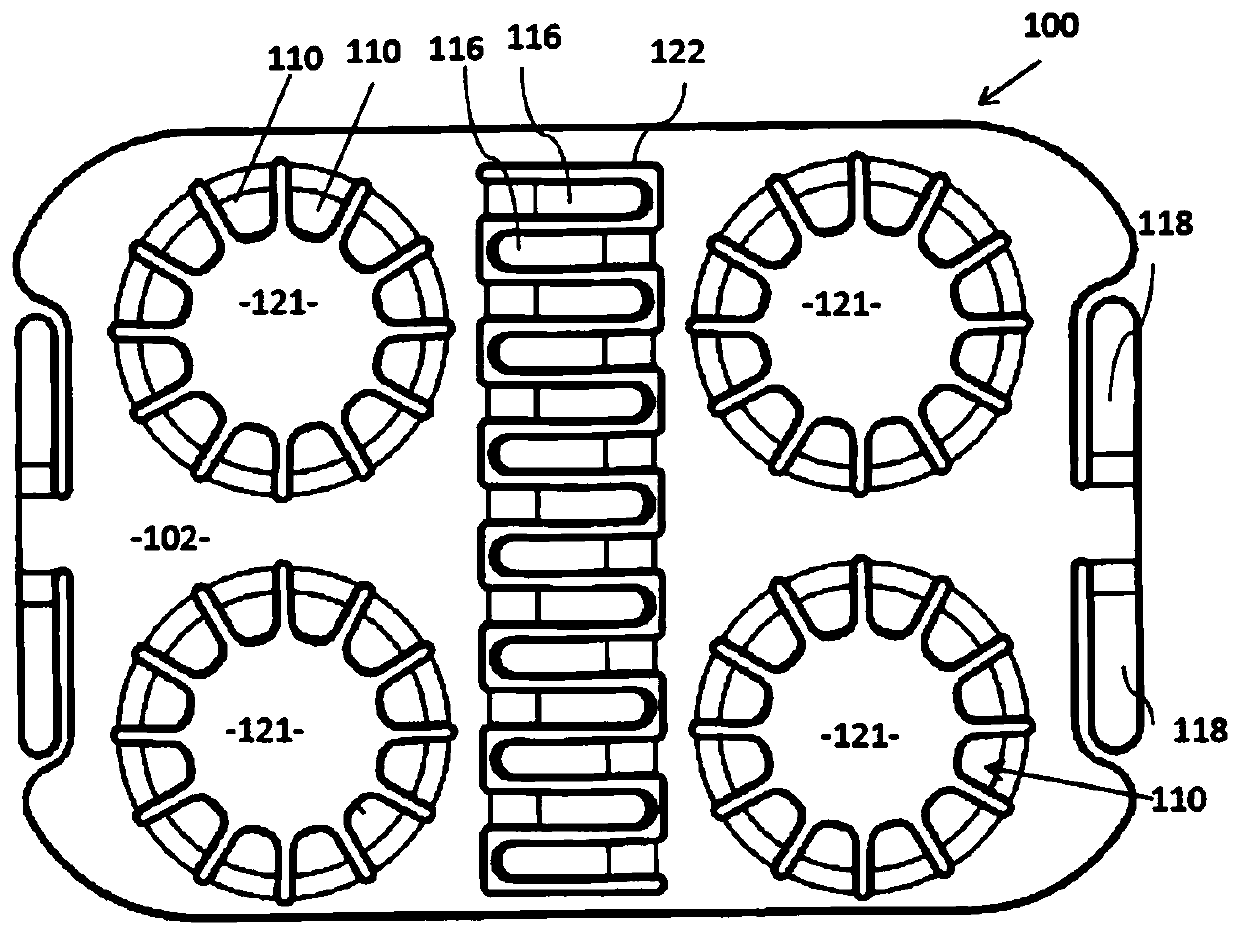

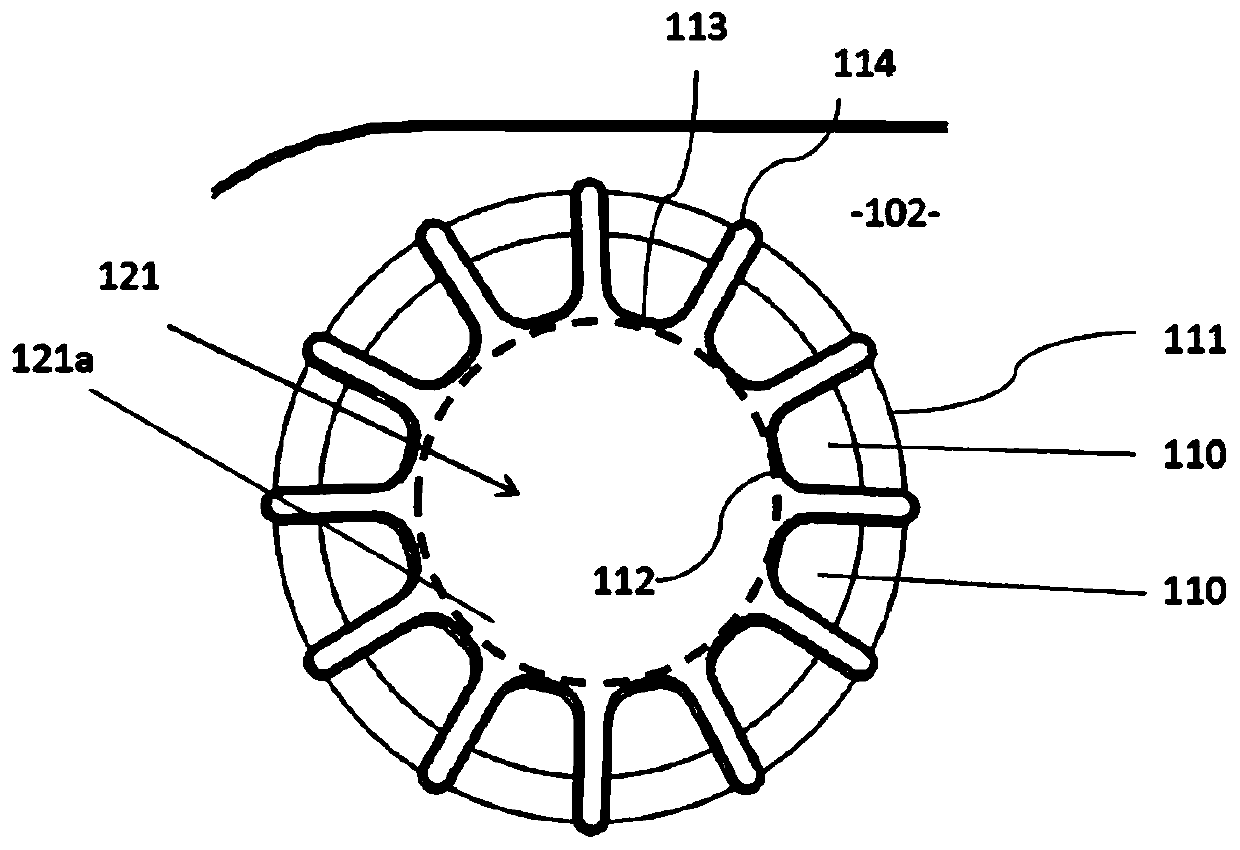

[0036] will now refer to Figure 2 to Figure 4 An example of a pressing element 100 is given. The pressing element 100 includes a plate-shaped portion 102 and several spring inserts 110 . Each spring tab 110 has a first end 111 forming part of the plate-shaped portion 102 . The second end 112 of the spring tab 110 is located distally with respect to the first end 111 and is configured to press against the body 150 on which the pressing element 100 exerts a force. The plate-shaped part 102 comprises a first through-hole 121 , all edges of which are formed by spring tabs 110 . The spring tabs 110 are thus all juxtaposed against each other along the edge of the aperture 121 . exist figure 1 In the prior art shown in , the spring tabs 16 are connected by a straight portion of the edge of the aperture 14 . The two spring tabs 16 are separated from each other. In the pressing element 100 , the edge of the through-hole 121 is completely delimited by the spring tongue 110 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com