Model placing rack for product design

A technology for product design and shelf placement, applied in applications, display hangers, display shelves, etc., can solve problems such as easy to drop, poor safety, and inconvenient product model observation, and achieve high safety and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

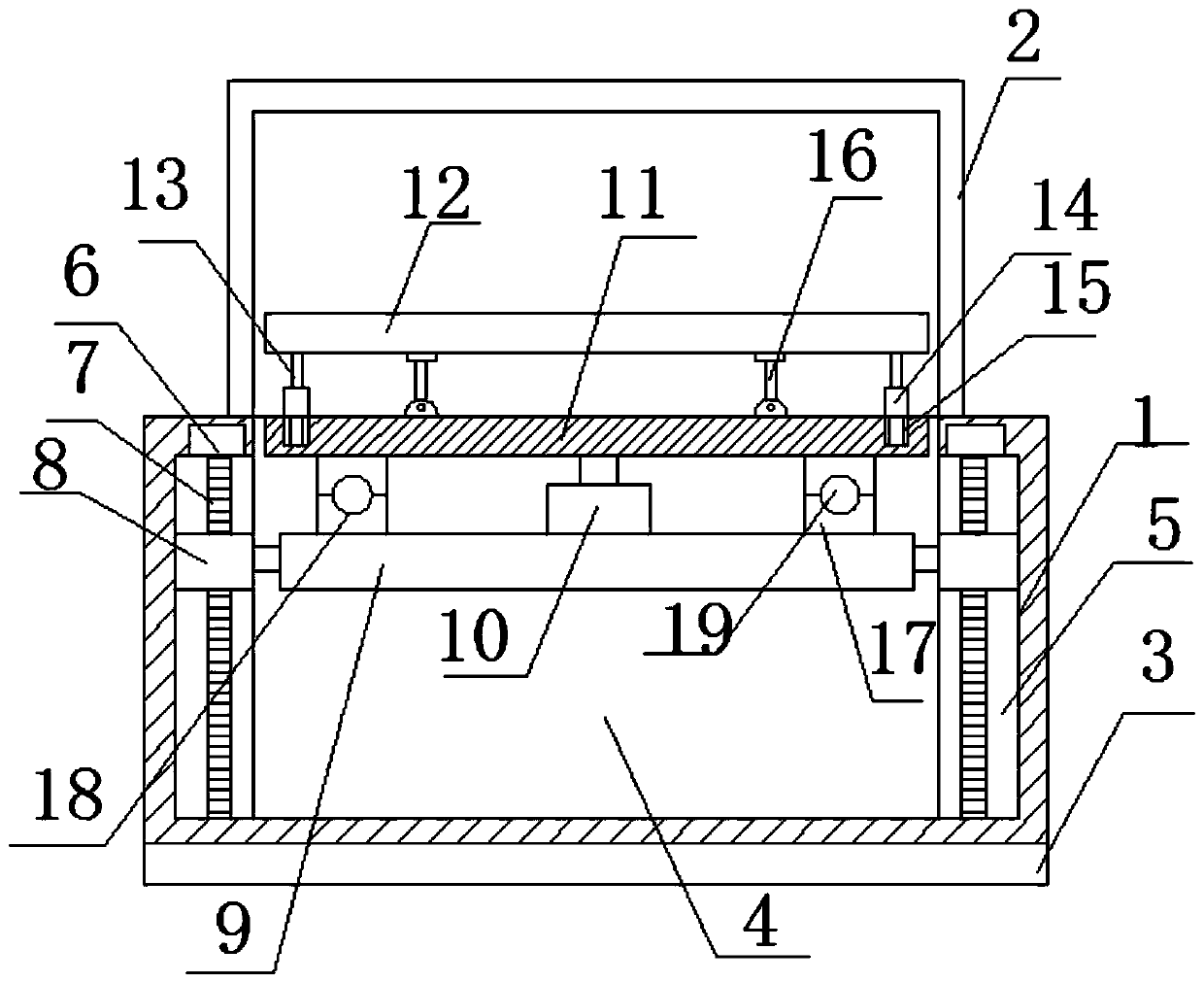

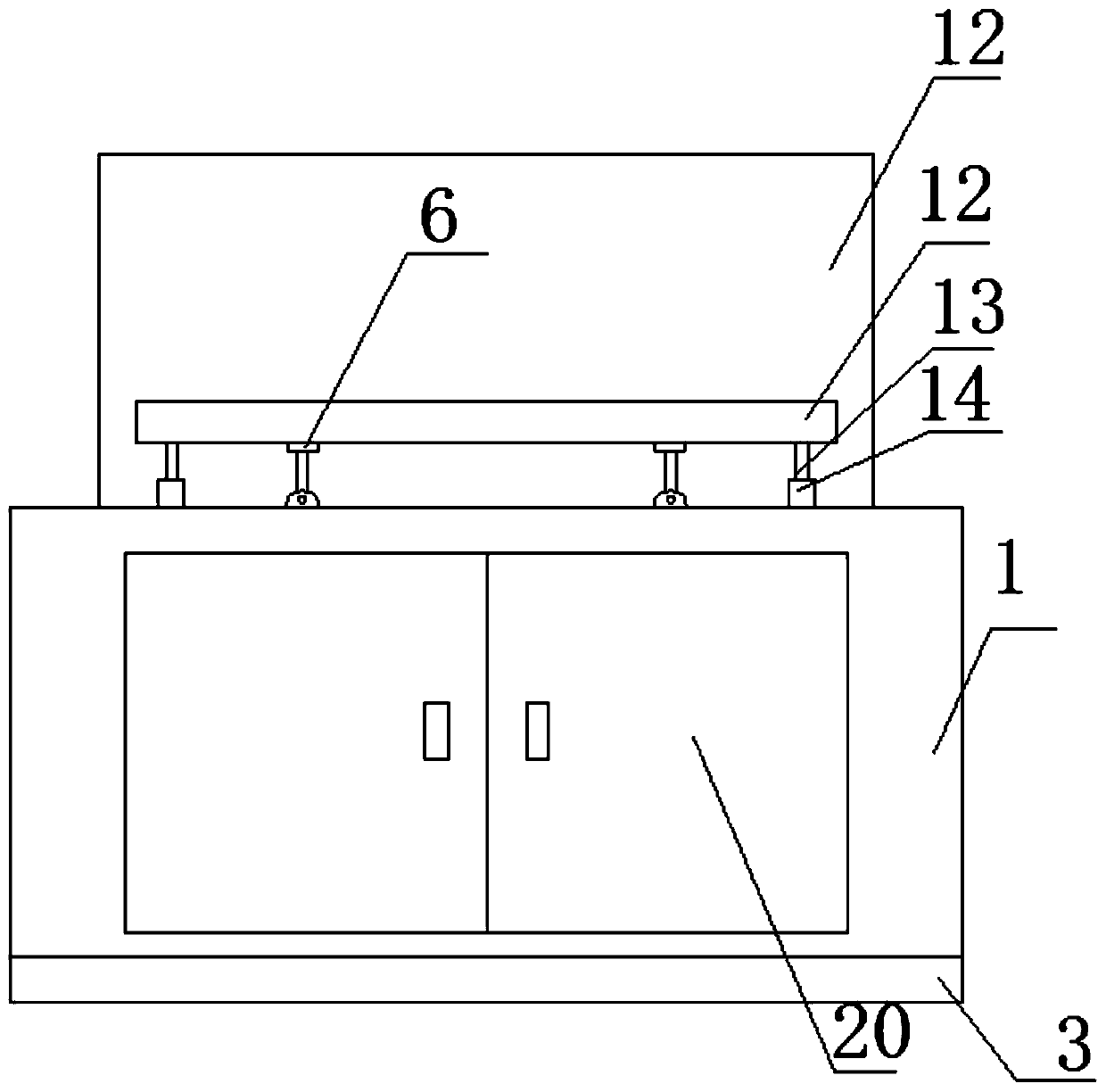

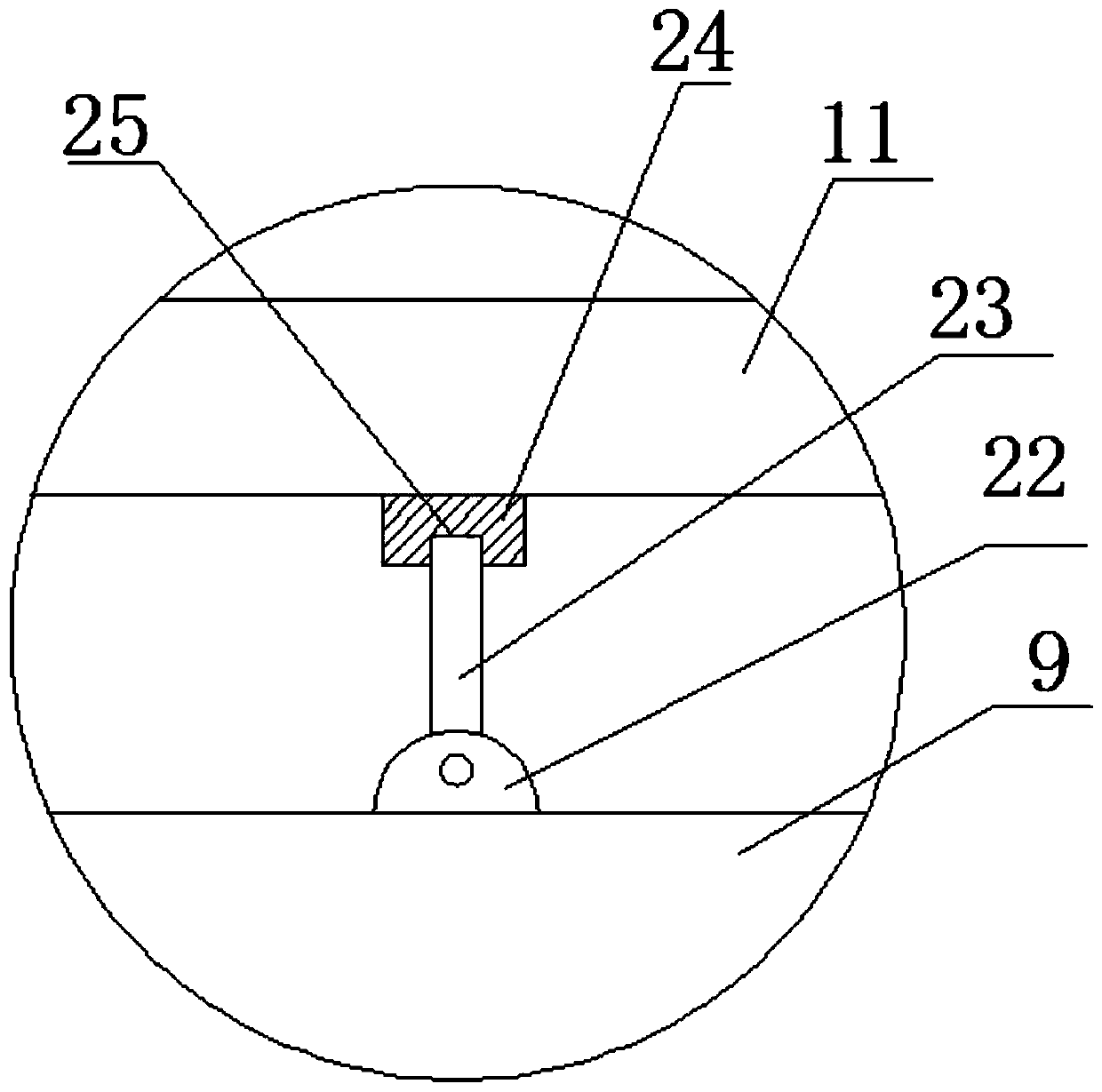

[0021] see Figure 1~3 , in the embodiment of the present invention, a kind of product design model placement rack, comprises workbench 1, and the upper end of described workbench 1 is provided with glass cover 2, and the lower end of workbench 1 is provided with anti-slip pad 3, and the inside of workbench 1 A cavity 4 is provided, the front side of the cavity 4 is provided with a box door 20, the left and right ends of the cavity 4 are provided with a lifting chamber 5, and the upper end of the lifting chamber 5 is provided with a lifting motor 6, and the lifting motor 6 The output end of 6 is provided with a threaded rod 7, and the threaded rod 7 is threaded with a lifting seat 8, and a lifting plate 9 is arranged between the two lifting seats 8, and a rotating motor 10 is arranged in the middle of the upper side of the lifting plate 9. The upper end of the rotating motor 10 is provided with a rotating plate 11, the top of the rotating plate 11 is provided with a placement ...

Embodiment 2

[0024] On the basis of Embodiment 1, the anti-slip mat 3 is an ABS anti-slip mat, and the lower side of the anti-slip mat 3 is provided with a number of adsorption grooves. It can play the role of anti-slip and improve the stability of the device when it is working.

Embodiment 3

[0026] refer to Figure 4 , On the basis of Embodiment 1 or Embodiment 2, a protective cover 26 is provided on the outside of the rotating electrical machine 10, and a sound insulation pad 27 is provided between the protective cover 26 and the rotating electrical machine 10, which can reduce the noise generated by the motor operation , to improve the comfort of use, a shock-absorbing pad 28 is arranged between the sound-insulating pad 27 and the rotating motor 10, which can reduce the vibration generated when the motor works, and the protective cover 26 is made of heat-dissipating material, and the protective cover 26 is connected with the rotating motor A number of heat conducting rods 29 are arranged between the motors 10 , and a number of cooling fins 30 are arranged outside the protective cover 26 . It is convenient to dissipate the heat of the motor and realize the protection of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com