Defoaming and density measuring system for slurry outside desulfurizing absorption tower

A desulfurization absorption tower, density measurement technology, applied in chemical instruments and methods, separation methods, measuring devices, etc., to save time, easy to connect, easy to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

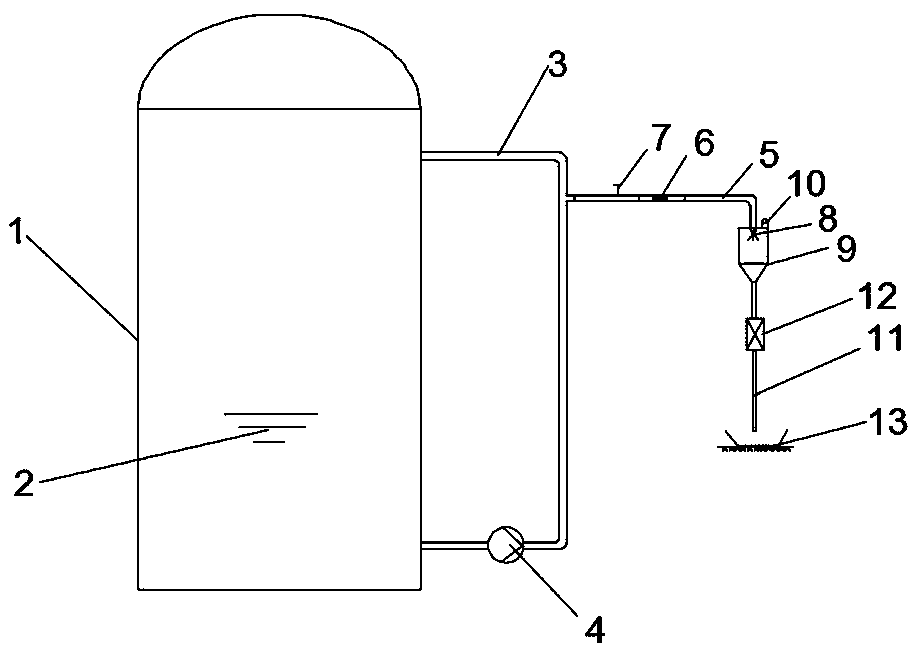

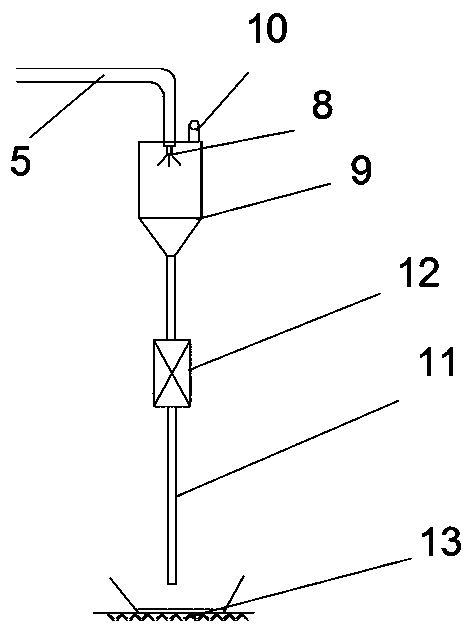

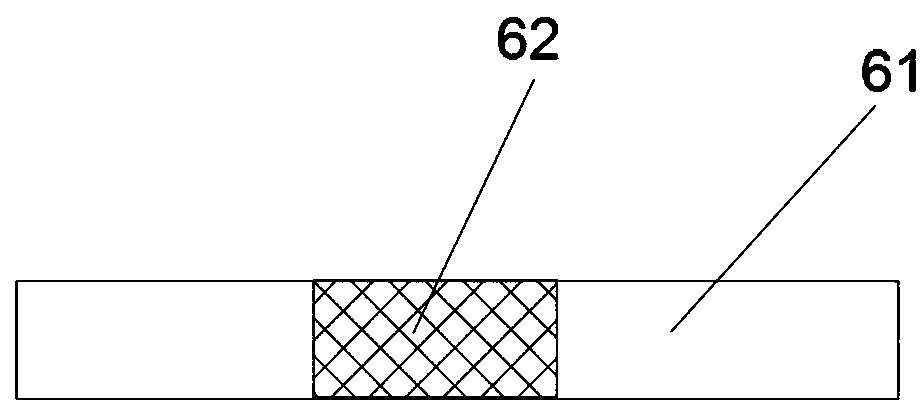

[0032] Such as figure 1 and figure 2 As shown, a slurry defoaming and density measurement system outside the desulfurization absorption tower includes an absorption tower 1, a slurry 2 located in the absorption tower 1, a slurry discharge pipeline 3 and a slurry discharge pump 4 connected to the absorption tower 1, connected to The defoaming pipeline 5 on the slurry pipeline 3, the buffer device 6 connected to the defoaming pipeline 5, the nozzle 8 connected to the downstream end of the defoaming pipeline 5, the defoaming box 9 connected to the bottom of the nozzle 8, the defoaming box 9 connected to the defoaming pipeline The discharge pipe 11 at the bottom of the bubble box 9 , the density meter 12 connected to the discharge pipe 11 and the trench 13 connected to the discharge pipe 11 below.

[0033] In this embodiment, the slurry pipeline 3 is the external circulation pipeline of the absorption tower 1 and the slurry pump 4 is threadedly connected to the circulation pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com