Aviation steel pipe polishing device

A steel pipe and aviation technology, which is applied in the field of aviation steel pipe grinding devices, can solve the problems of low grinding efficiency, poor cleaning, dust residue, etc., and achieve the effects of improving grinding efficiency, improving operating efficiency, and efficient suction and collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] see Figure 1-4 , In an embodiment of the present invention, an aviation steel pipe grinding device includes a box body 1, a moving clamping mechanism and a grinding mechanism.

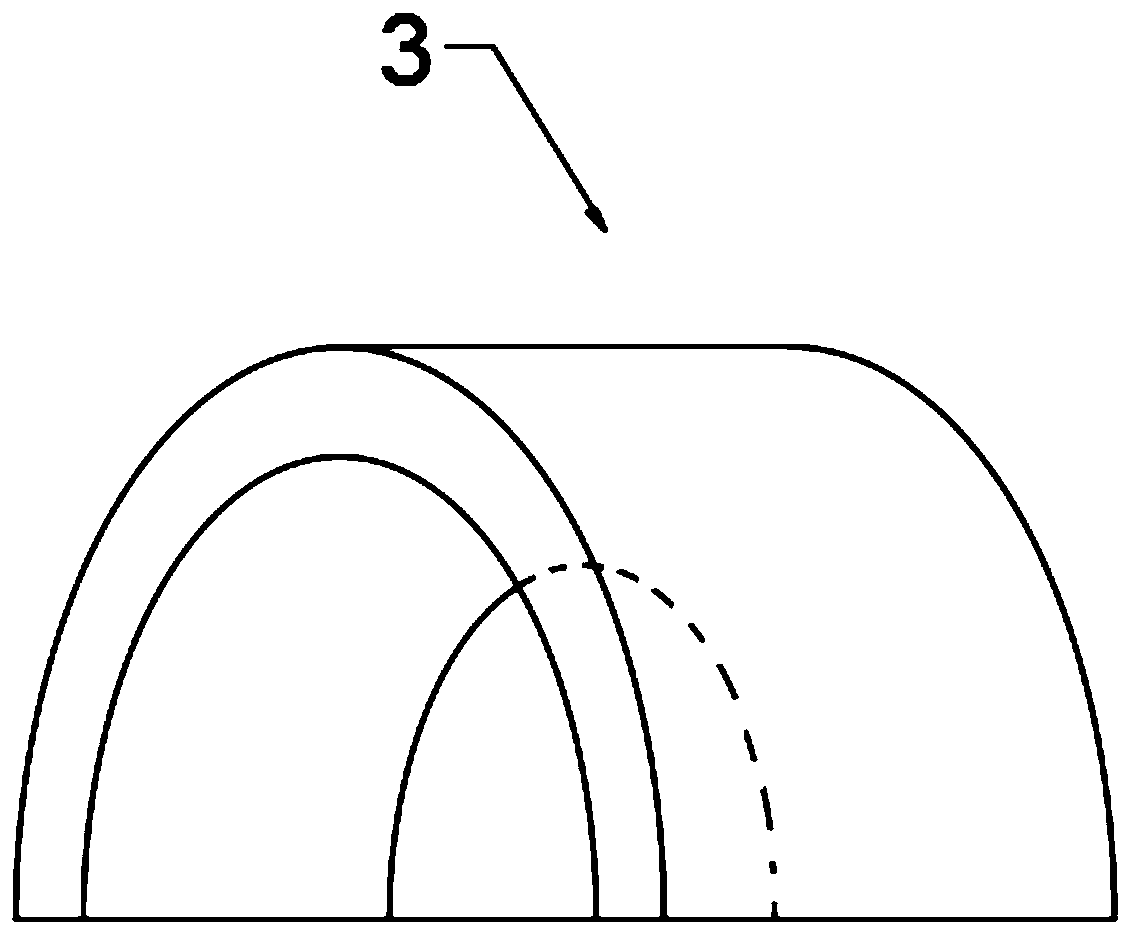

[0022] Described mobile clamping mechanism comprises moving plate 2, and one side of moving plate 2 is provided with a group of clamping plates 3 that are arranged symmetrically, and clamping plate 3 is arc-shaped plate, and clamping plate 3 is provided with arc-shaped groove, is convenient to The steel pipe is clamped; one end of the clamping plate 3 is nested in the moving plate 2, the moving plate 2 is provided with a vertical chute, the moving plate 2 is provided with a two-way screw rod 4, and the two-way screw rod 4 runs through the clamping plate 3 and is threadedly connected with the clamping plate 3; the two-way screw rod 4 is sleeved with a worm gear 5, the worm gear 5 is engaged with a worm 6, and the worm 6 extends to the outside of the moving plate 2 and is fixedly connected with a...

Embodiment 2

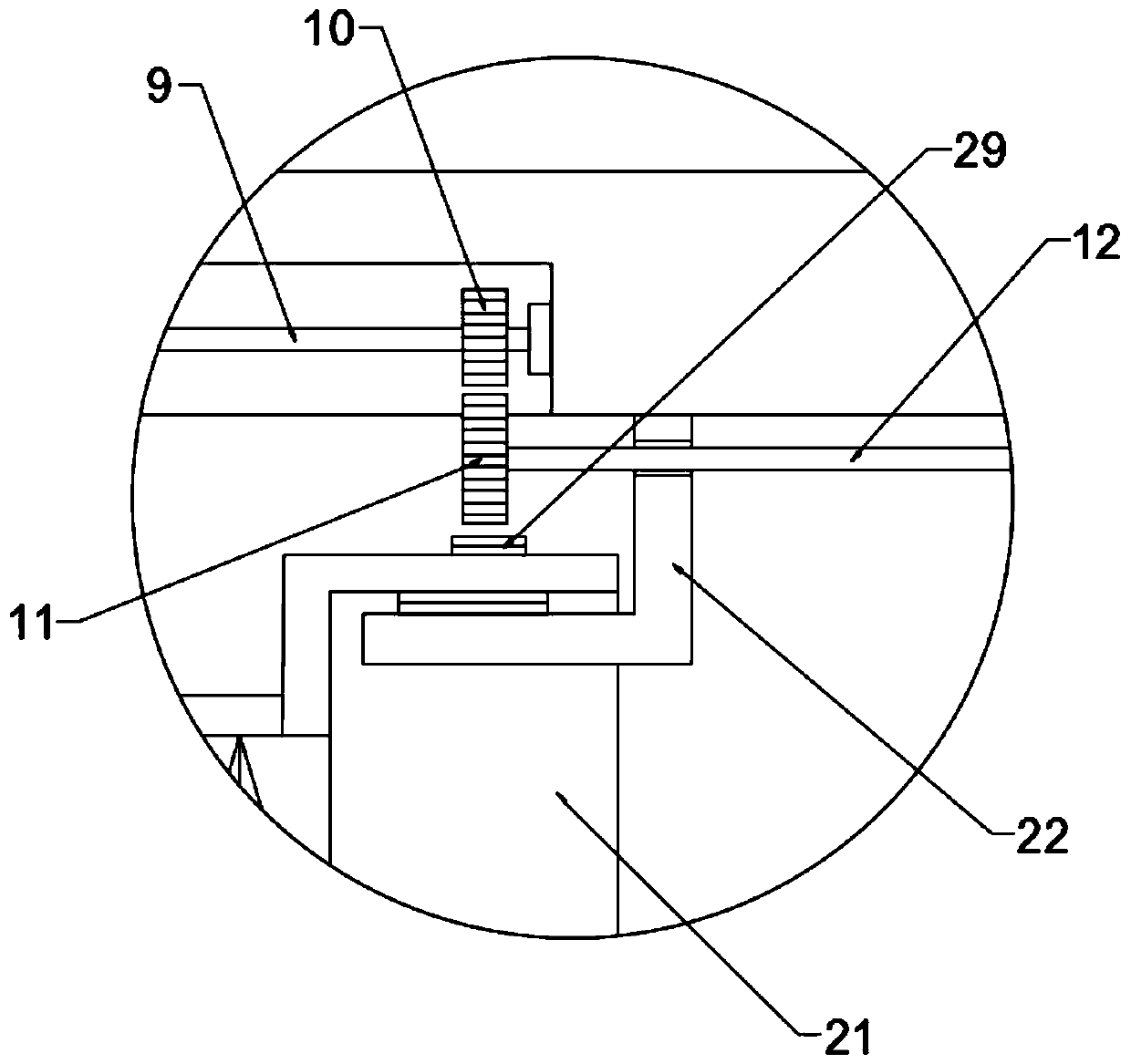

[0025] The difference between this embodiment and Embodiment 1 is that: the box body 1 is provided with a dust collection mechanism, the dust collection mechanism includes a blower 27, the blower 27 is connected with an air inlet pipe 26, the second rotating shaft 14 and the grinding shaft 18 are both hollow Pipe, the grinding shaft 18 is provided with evenly distributed air holes 29, the air inlet pipe 26 communicates with the second rotating shaft 14 through the rotary joint, the second rotating shaft 14 communicates with the grinding shaft 18, and the airflow generated by the blower 27 enters through the second rotating shaft 14 Grind the shaft 18 and discharge it from the air hole 29, and then blow the dust generated by the grinding of the inner wall of the steel pipe out of the steel pipe, so as to realize the rapid cleaning of the inner wall of the steel pipe; the grid plate 24 of the bottom plate of the box body 1 is provided with a collection tank below the grid net 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com