Method and system for calculating replacement rate of dual-fuel engine

A dual-fuel engine, replacement rate technology, applied in the direction of engine control, machine/engine, fuel injection control, etc., can solve the problems of increasing inaccuracy, many operating conditions, and long calibration time, so as to reduce the error rate, The effect of low cost and optimized structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

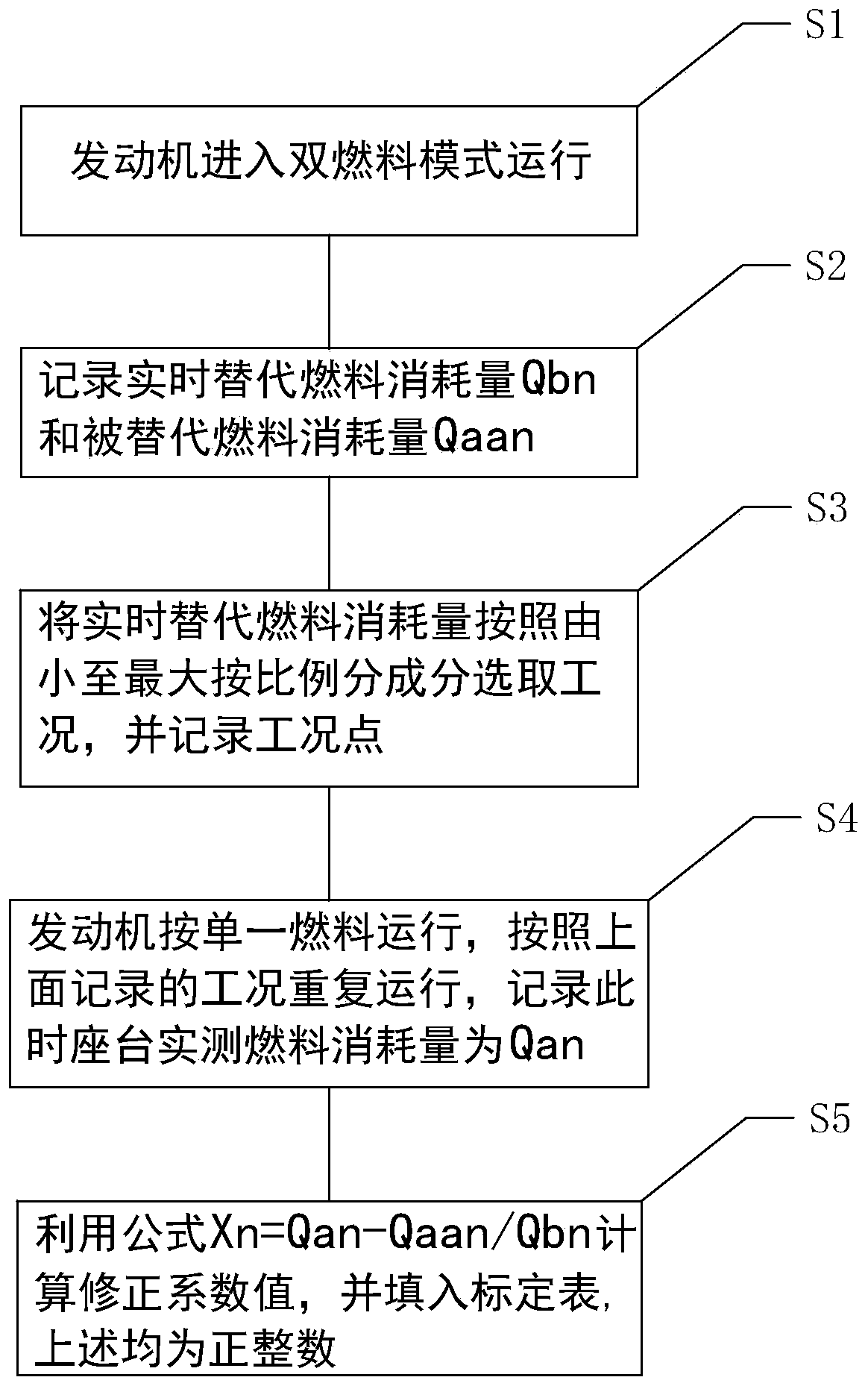

[0041] A method for calculating the replacement rate of a dual-fuel engine, comprising the following steps:

[0042] Step 1. Obtain real-time substitute fuel consumption and replaced fuel consumption in dual-fuel mode; this real-time substitute fuel consumption and replaced fuel consumption can be calculated in real time for electronically controlled models, and can also be used for non-electronically controlled models Or it can be obtained by installing a fuel quality analysis device on the electronic control model;

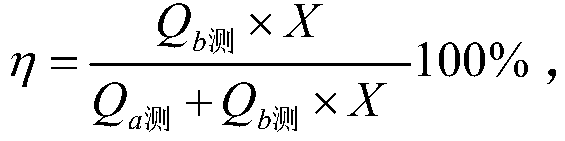

[0043] Step 2. Use the formula Calculate the substitution rate,

[0044] where Q b测 For real-time measurement of alternative fuel consumption in dual-fuel mode, Q a测 In order to measure the consumption of replaced fuel in real-time in dual-fuel mode, X is the correction coefficient;

[0045] The correction coefficient is a calibration value, which can be obtained from the calibration table according to the consumption of alternative fuels.

[0046] In the ...

Embodiment 2

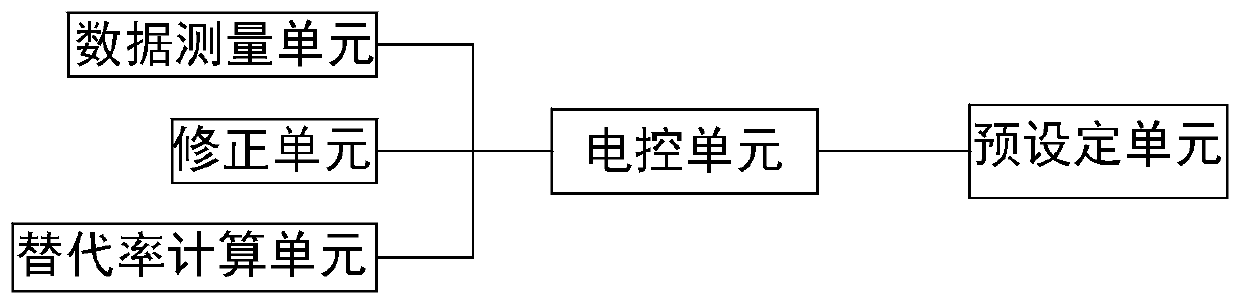

[0058] like figure 2As shown, a system for calculating the replacement rate of a dual-fuel engine includes a control unit, a data measurement unit electrically connected to the control unit, a correction unit and a replacement rate calculation unit. In this example, the control unit is integrated on the electronic control unit of the engine, which optimizes the structure and reduces the cost. Of course, the system can be directly set in the instrument, and the control unit can be a microprocessor at this time.

[0059] Among them, the data measurement unit is used to measure the consumption of alternative fuel and the consumption of replaced fuel;

[0060] Among them, the correction unit checks the calibration table according to the measured consumption of alternative fuels, and obtains the correction coefficient;

[0061] The substitution rate calculation unit calculates the substitution rate according to the following formula,

[0062]

[0063] where Q b测 For real-ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com