Motorcycle electric injection intake manifold

A technology for intake manifolds and motorcycles, which is applied in the direction of fuel air intake, fuel injection devices, combustion air/combustion-air treatment, etc., and can solve the problem of inability to arrange T-MAP electronic integration components and T-MAP detection values Problems such as distortion, small space of the motorcycle, etc., to achieve the effect of simple and compact overall structure, firm and reliable installation, convenient and easy manufacturing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

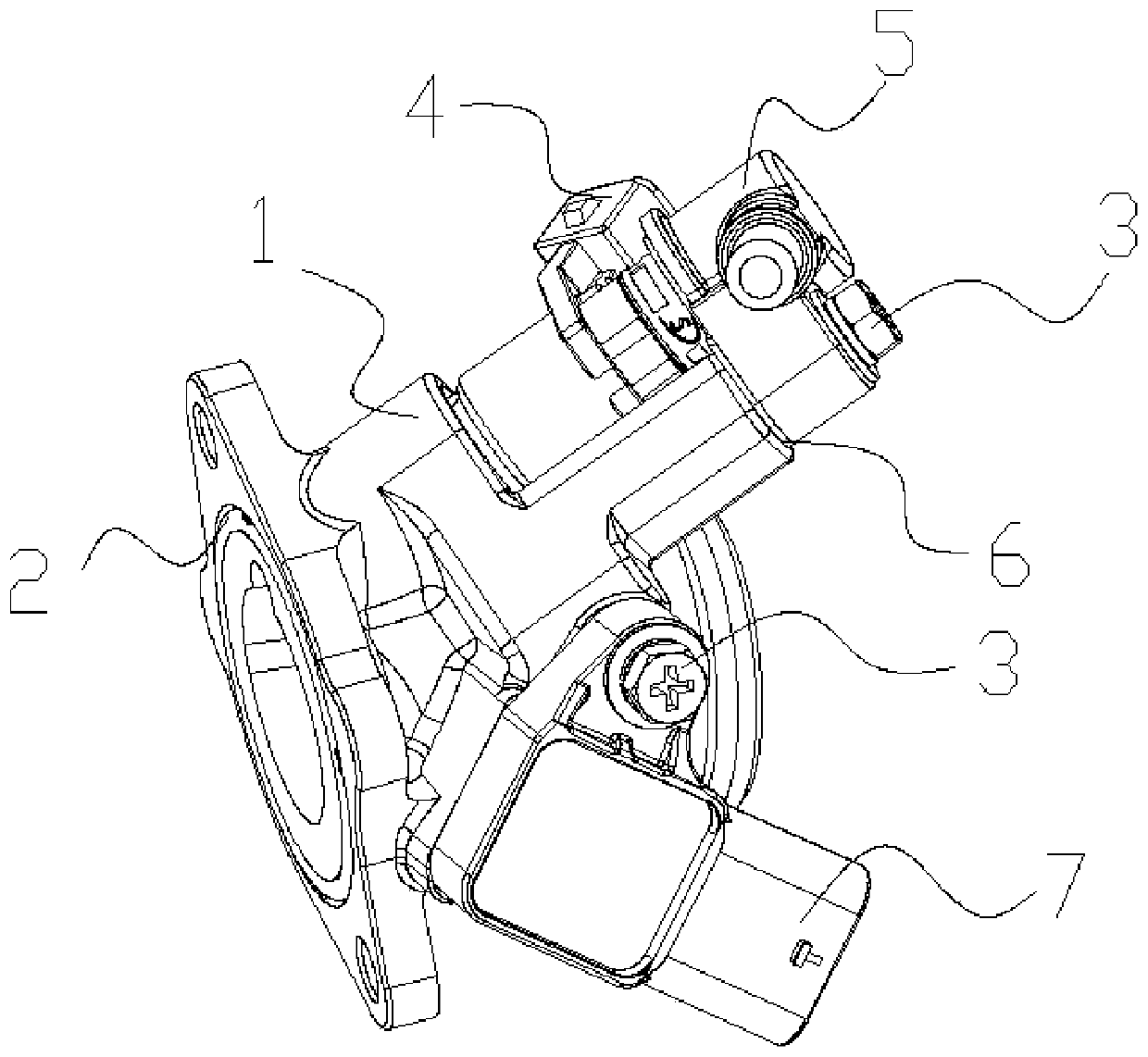

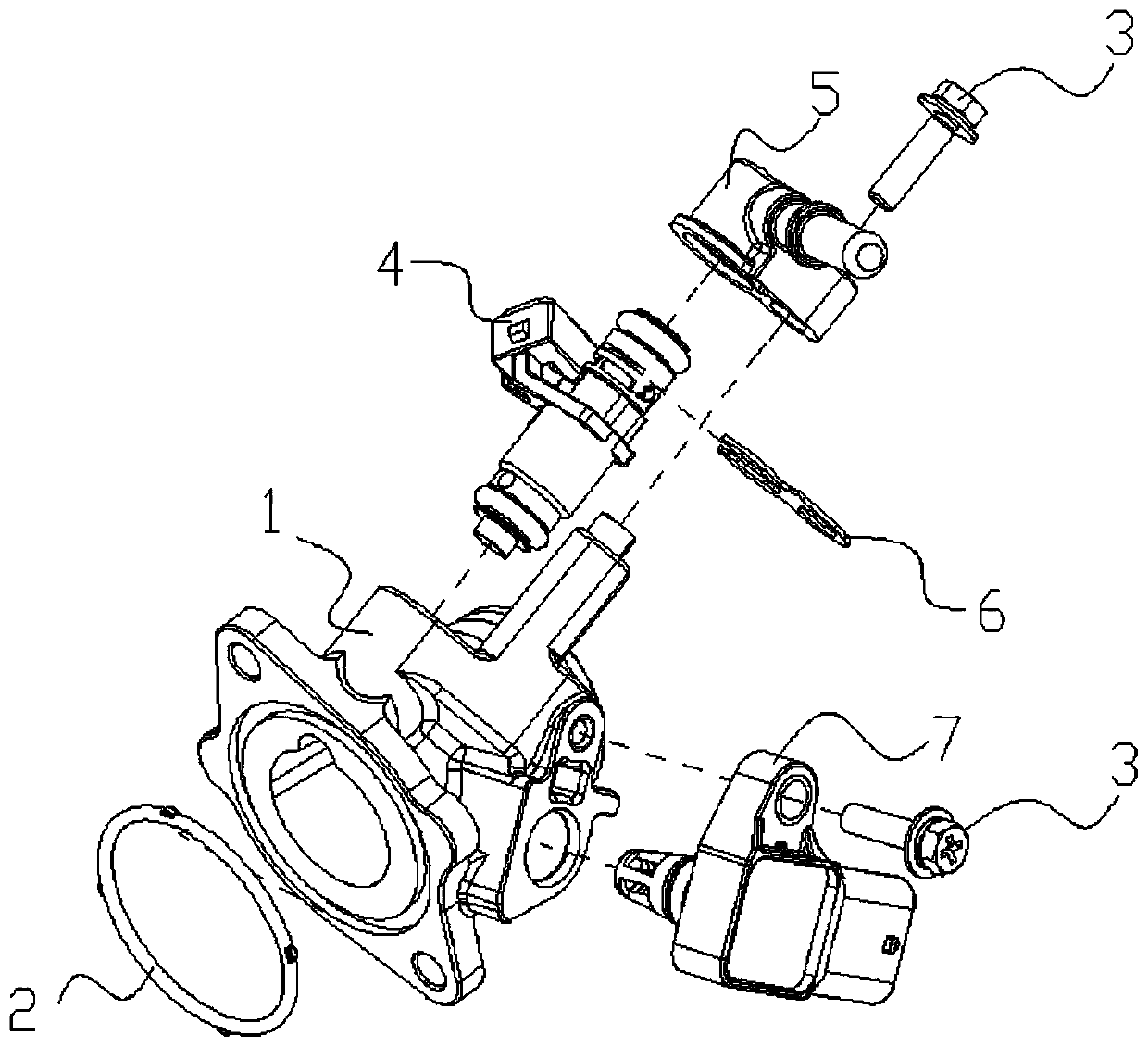

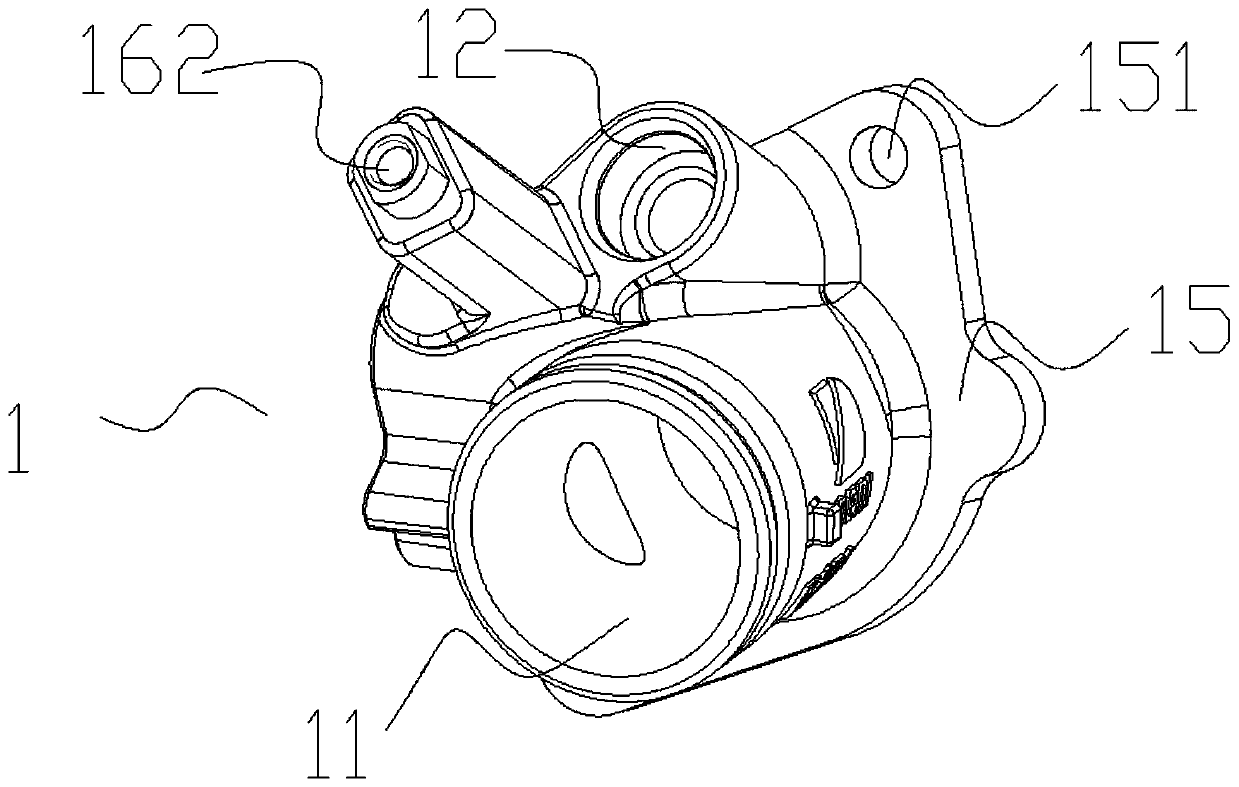

[0050] Such as Figure 1 to Figure 9 As shown, this embodiment provides an EFI intake manifold for a motorcycle, which mainly includes a manifold body 1, a numerical detection device, a sealing connector, an EFI actuator and an anti-rotation structure.

[0051] One end of the manifold body 1 is set as an air intake end, and an air intake hole 11 is arranged on the air intake end, and the other end is set as an oil outlet end, and an oil outlet hole 13 is arranged on the oil outlet end. As a preferred solution, the oil outlet end is provided with a connecting flange 15, and the connecting flange 15 is provided with two body through holes 151 for connecting and fixing with the engine.

[0052] The numerical detection device includes a T-MAP7, and the manifold body 1 is provided with a T-MAP hole 14 compatible with the T-MAP7, and the T-MAP hole 14 is connected to the manifold body 1. The inner channels are connected; the working end of the T-MAP7 is inserted into the hole 14 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com