Traveling device for detecting internal quality of concrete pipeline and operation method

An internal quality, walking device technology, applied in special pipes, pipe components, pipes/pipe joints/pipe fittings, etc., can solve the problems of complex structure, inability to contact and fit the inner wall of the pipe, and inability to achieve walking, etc., to ensure reliability and stability. The effect of ensuring the quality of testing and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

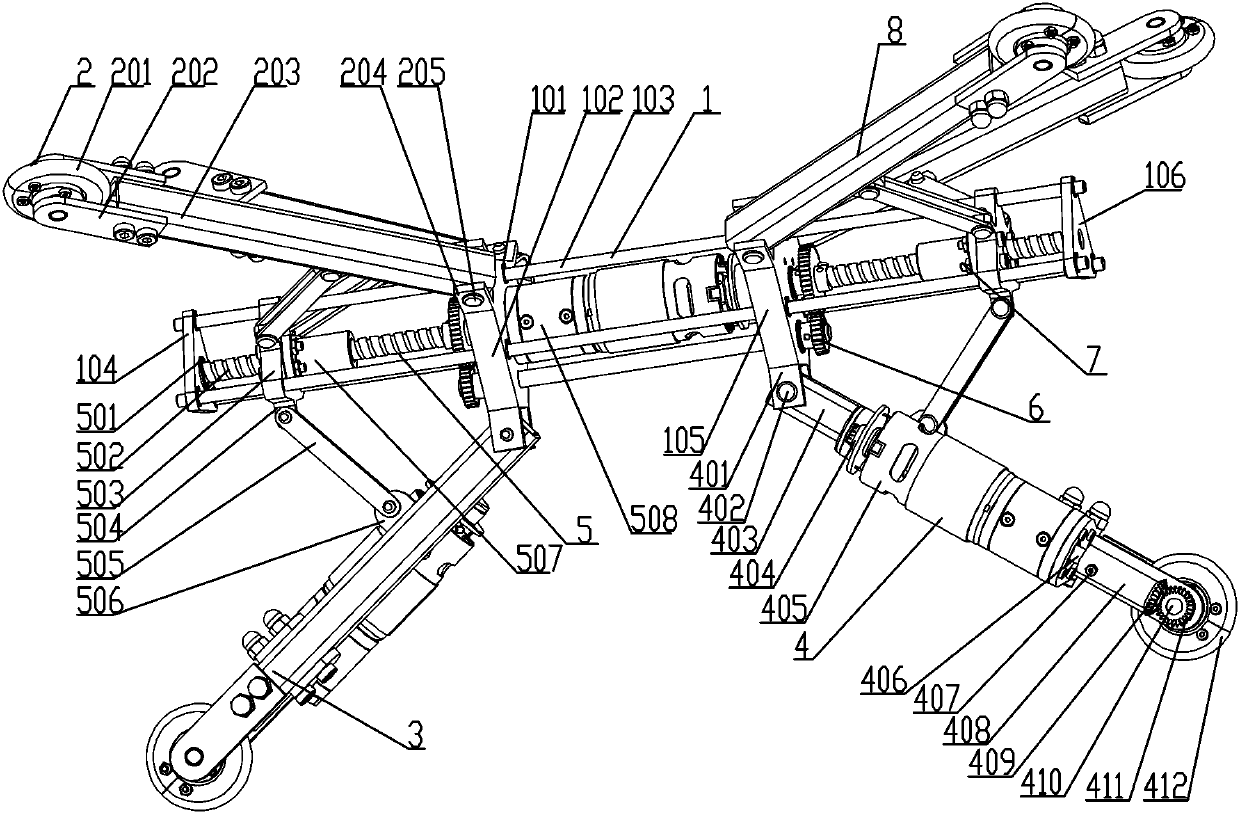

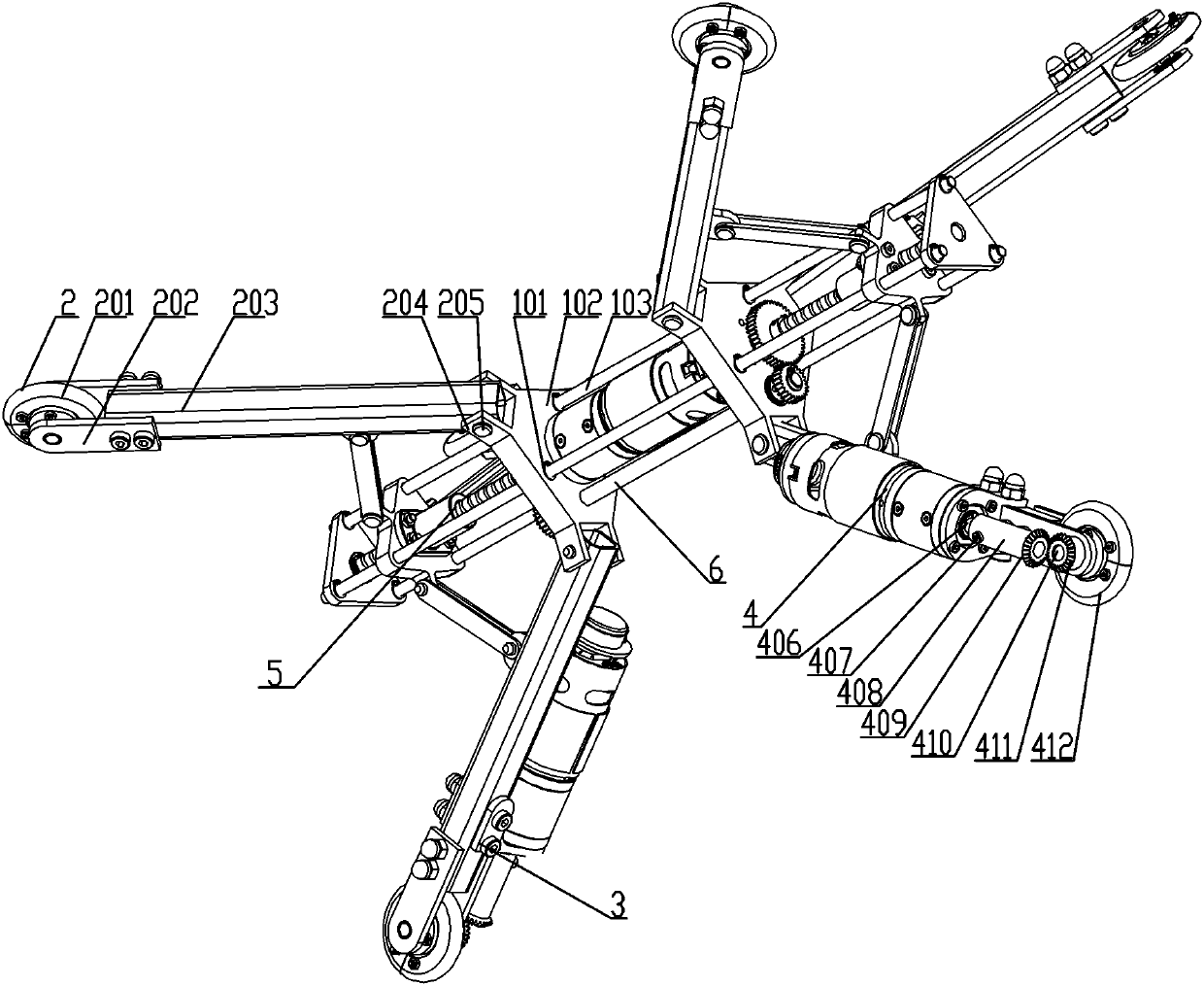

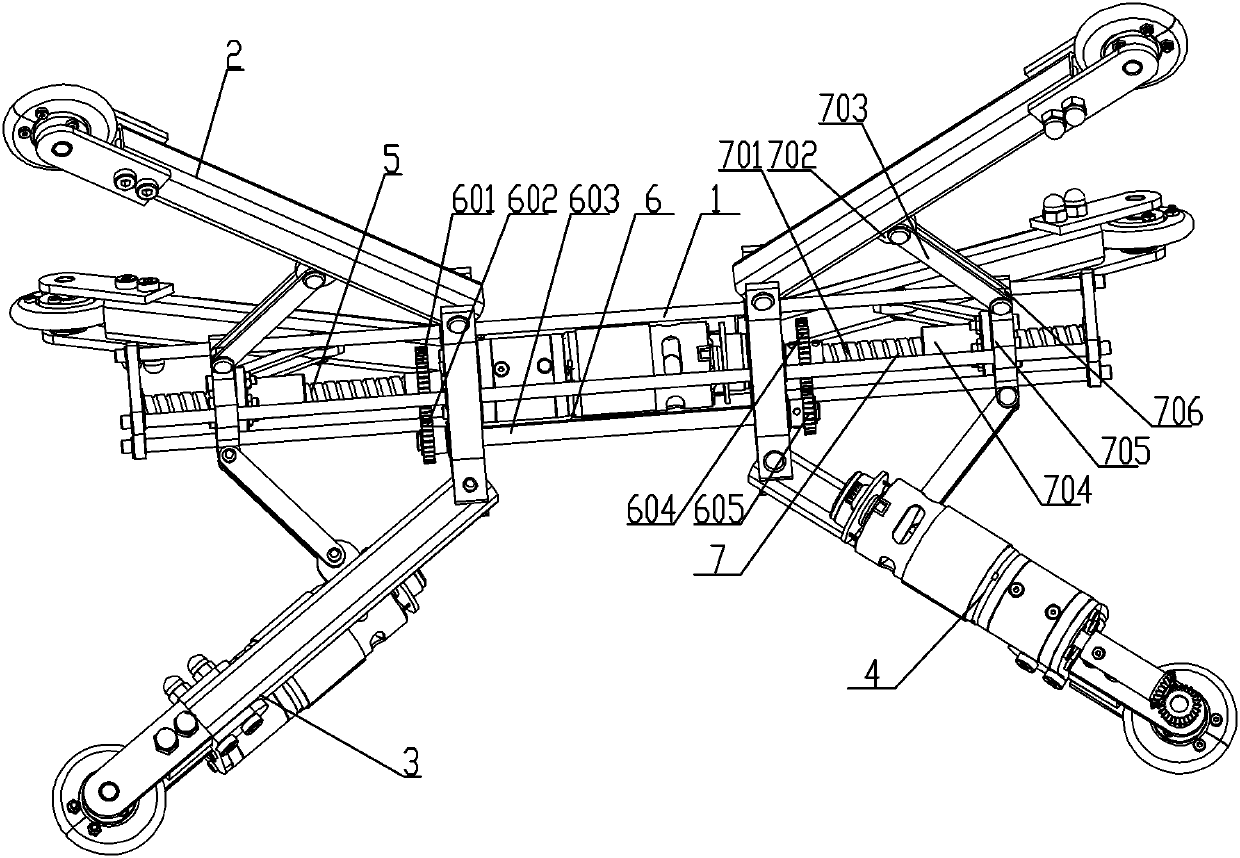

[0049] see Figure 1-5 , the walking device for the internal quality inspection of concrete pipelines, which includes a frame structure 1, the first middle support plate 102 of the frame structure 1 is connected with a head wheel set 3 and two groups of walking wheels for supporting and walking with the inner wall of the pipeline The head support wheel set 2, the head walking wheel set 3 and the head support wheel set 2 are evenly distributed on the outer edge of the first middle support plate 102; on the second middle support plate 105 of the frame structure 1 A tail walking wheel set 4 and two sets of tail supporting wheels 8 for supporting and walking on the inner wall of the pipeline are connected, and the tail walking wheels 4 and tail supporting wheels 8 are evenly distributed on the outer edge of the second middle support plate 105 ; The frame structure 1 is equipped with a head opening device 5 for driving the head walking wheel set 3 and the head supporting wheel set ...

Embodiment 2

[0060] The operation method of the walking device for the internal quality detection of the concrete pipeline comprises the following steps:

[0061] Step 1: Fixedly install professional testing equipment for internal quality testing of concrete pipelines on the frame structure 1;

[0062] Step 2: Place the walking device as a whole at the opening of the concrete pipeline to be tested;

[0063] Step 3: The opening motor 508 of the remote control detection equipment and the head opening device 5 is turned on, the driving screw 502 is driven by the opening motor 508, the screw nut 507 is driven by the driving screw 502, and the connecting screw nut 507 is driven Rod 505, and then drive the head walking wheel set 3 and the head support wheel set 2 to open synchronously by the connecting rod 505, and make the head wheel 201 and the walking wheel close to the inner wall of the concrete pipe;

[0064] Step 4: During the rotation of the transmission screw 502, drive the driving gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com