Heavy oil hydrotreatment catalyst carrier, catalyst and preparation method thereof

A catalyst carrier and heavy oil hydrogenation technology, applied in physical/chemical process catalysts, chemical instruments and methods, hydrocarbon oil treatment, etc., can solve problems such as catalyst strength reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

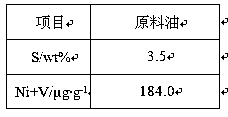

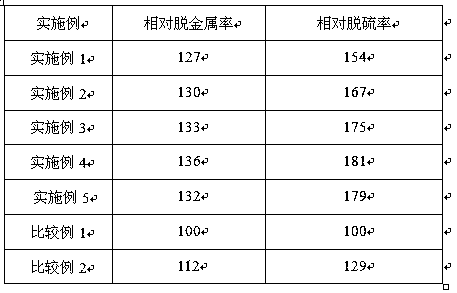

Examples

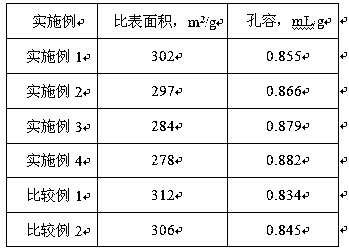

Embodiment 1

[0035] (1) Carrier preparation

[0036] 1000g pseudo-boehmite powder (commercially available, specific surface area 350m 2 / g, pore volume 1.15mL / g) was made into spherical particles by roll molding in a rolling ball machine. During the ball forming process, 14g of turnip powder and 850mL of ammonium dihydrogen phosphate with a concentration of 0.027g / mL were sprayed into the ball at the same time Aqueous solution, the speed of the ball rolling machine is 35 rpm, after the ball forming is completed, the carrier precursor is obtained; then the carrier precursor is subjected to water vapor treatment, the temperature is 190 ° C, and the time is 4h, wherein the water vapor and the carrier precursor A The volume space velocity is 800h -1 . The treated material was dried at 110°C for 8 hours, and then calcined at 700°C for 3 hours to obtain a spherical carrier with a particle size of 0.2-0.8 mm. The physical and chemical properties of the carrier are shown in Table 1, and the abra...

Embodiment 2

[0043] (1) Carrier preparation

[0044] 1000g pseudo-boehmite powder (commercially available, specific surface area 350m 2 / g, pore volume 1.15mL / g) was made into spherical particles by roll molding in a rolling ball machine. During the ball forming process, 14g of scallop powder and 850mL of diammonium hydrogen phosphate with a concentration of 0.046g / mL were sprayed at the same time Aqueous solution, the speed of the rolling ball machine is 35 rpm, after the ball is formed, the carrier precursor is obtained; then the carrier precursor is subjected to water vapor treatment, the temperature is 200 ° C, and the time is 4h, wherein the water vapor and the carrier precursor A The volume space velocity is 800h -1 . The treated material was dried at 110°C for 8 hours, and then calcined at 700°C for 3 hours to obtain a spherical carrier with a particle size of 0.2-0.8 mm. The physical and chemical properties of the carrier are shown in Table 1, and the abrasion data are shown in ...

Embodiment 3

[0051] (1) Carrier preparation

[0052] 1000g pseudo-boehmite powder (commercially available, specific surface area 350m 2 / g, pore volume 1.15mL / g) was made into spherical particles by roll molding in a rolling ball machine. During the ball forming process, 14g of turnip powder and 850mL of ammonium phosphate aqueous solution with a concentration of 0.069g / mL were sprayed in at the same time. The speed of the rolling ball machine is 35 rpm. After the ball forming is completed, the carrier precursor is prepared; then the carrier precursor is treated with water vapor at a temperature of 210 °C for 4 hours. The water vapor and the volume of the carrier precursor A The air speed is 800h -1 . The treated material was dried at 110°C for 8 hours, and then calcined at 700°C for 3 hours to obtain a spherical carrier with a particle size of 0.2-0.8 mm. The physical and chemical properties of the carrier are shown in Table 1, and the abrasion data are shown in Table 2.

[0053] (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com