Coal gangue grading recycling device

A coal gangue, No. 1 technology, applied in the field of coal gangue graded recovery and utilization devices, can solve problems such as silted rivers, spontaneous combustion of coal gangue, fires, air pollution, farmland and water bodies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

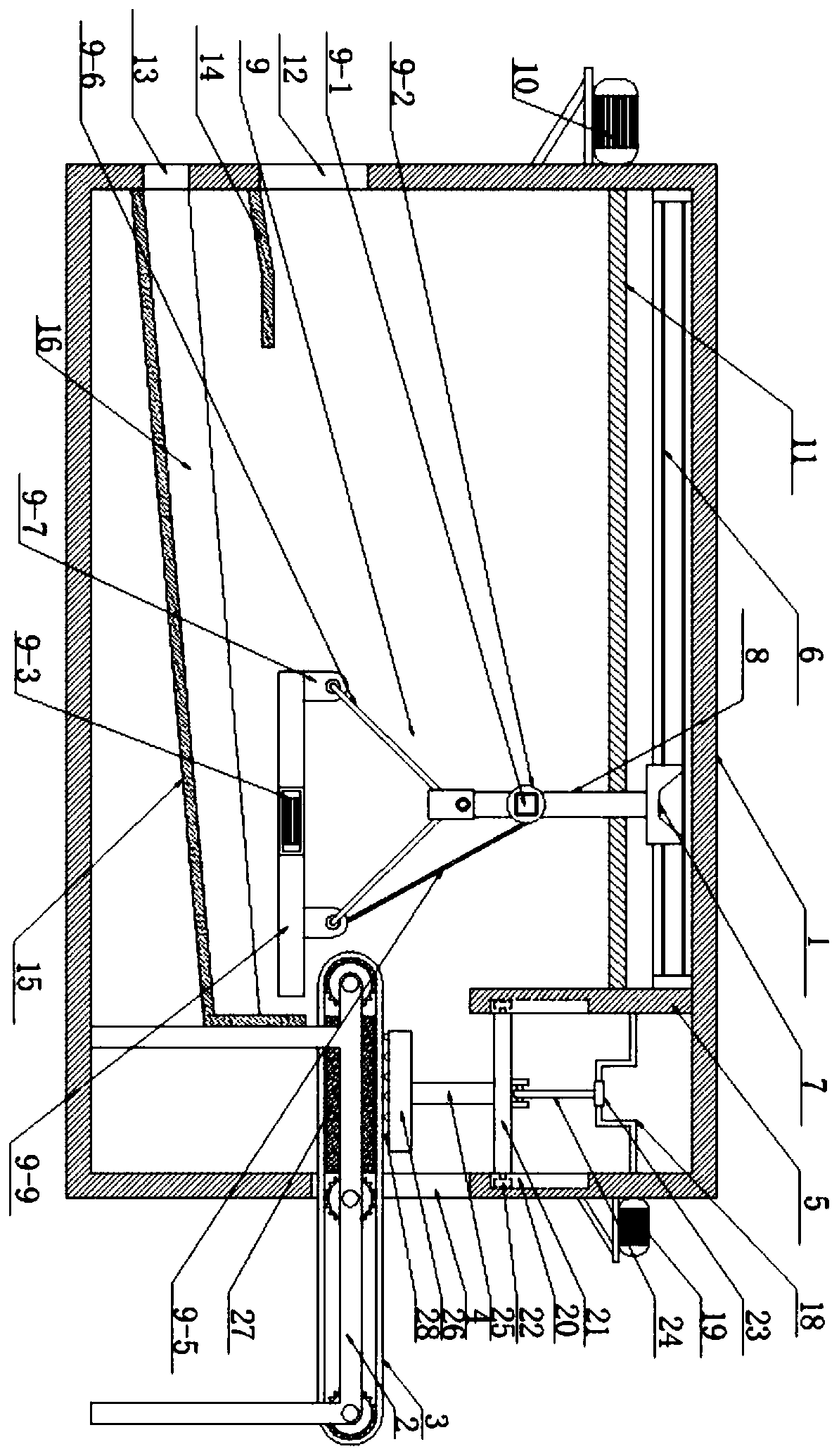

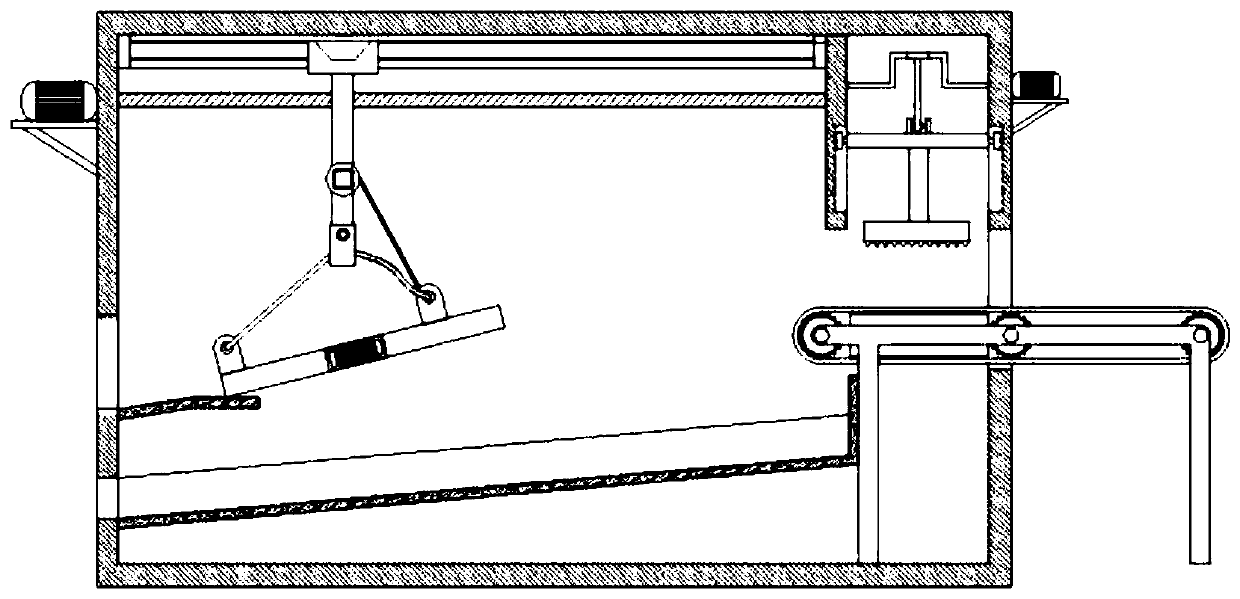

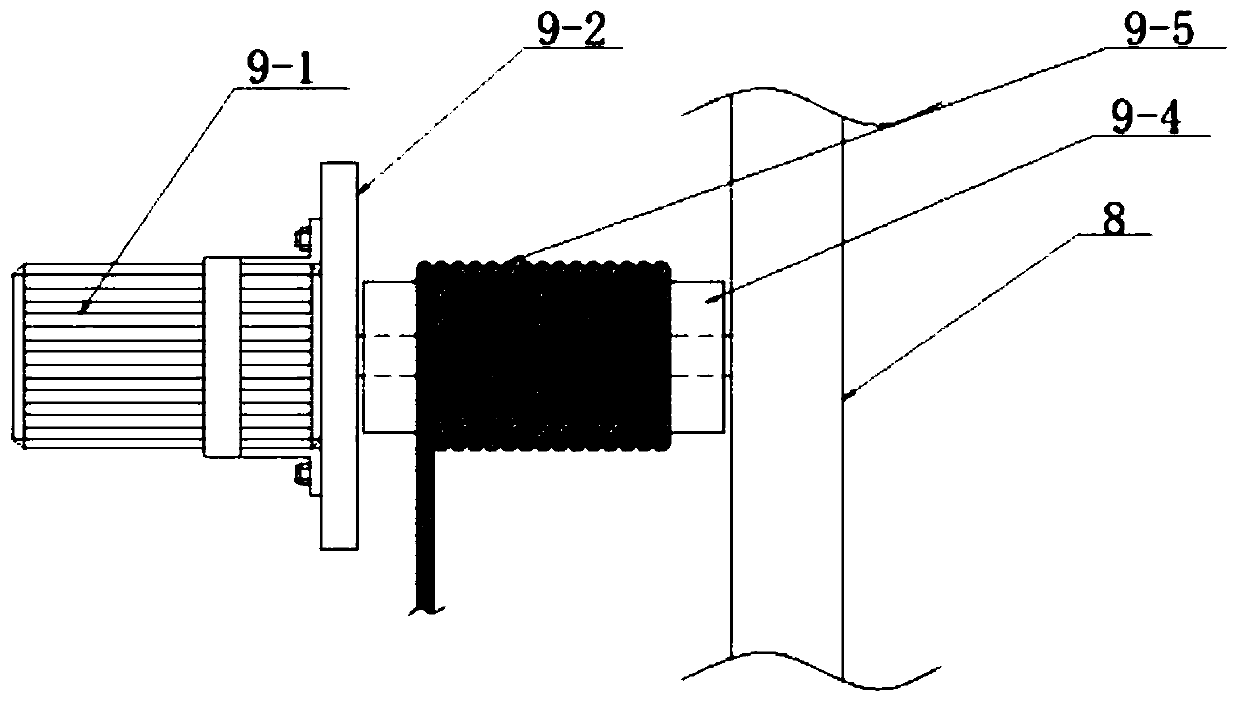

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] see as Figure 1-Figure 5 Shown, the technical scheme that this specific embodiment adopts is: it comprises casing 1 (length is 3500mm, width is 1500mm, height is the irony casing of 2000mm), frame 2, belt conveyor 3 (the model that adopts It is LZY-SS-ZWJD), feed port 4; the right side wall of box body 1 is fixed with feed port 4, and the middle part of feed port 4 is fixedly inserted with belt conveyor 3, belt conveyor 3 Transport the gangue raw material from the outside of the box 1 to the inside of the box 1, the belt conveyor 3 is installed on the frame 2 through bearings and welding rotation, and the left side of the frame 2 is fixedly welded inside the box 1 , the right side of the frame 2 is fixed on the ground on the right side of the box body 1 by bolts; the belt conveyor 3 is connected to an external power supply through a power cord, and the switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com