Novel full-automatic cleaning and drying all-in-one machine

A fully automatic cleaning and all-in-one technology, applied in dryers, drying, drying gas layout, etc., can solve the problems of low production efficiency, low work efficiency and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

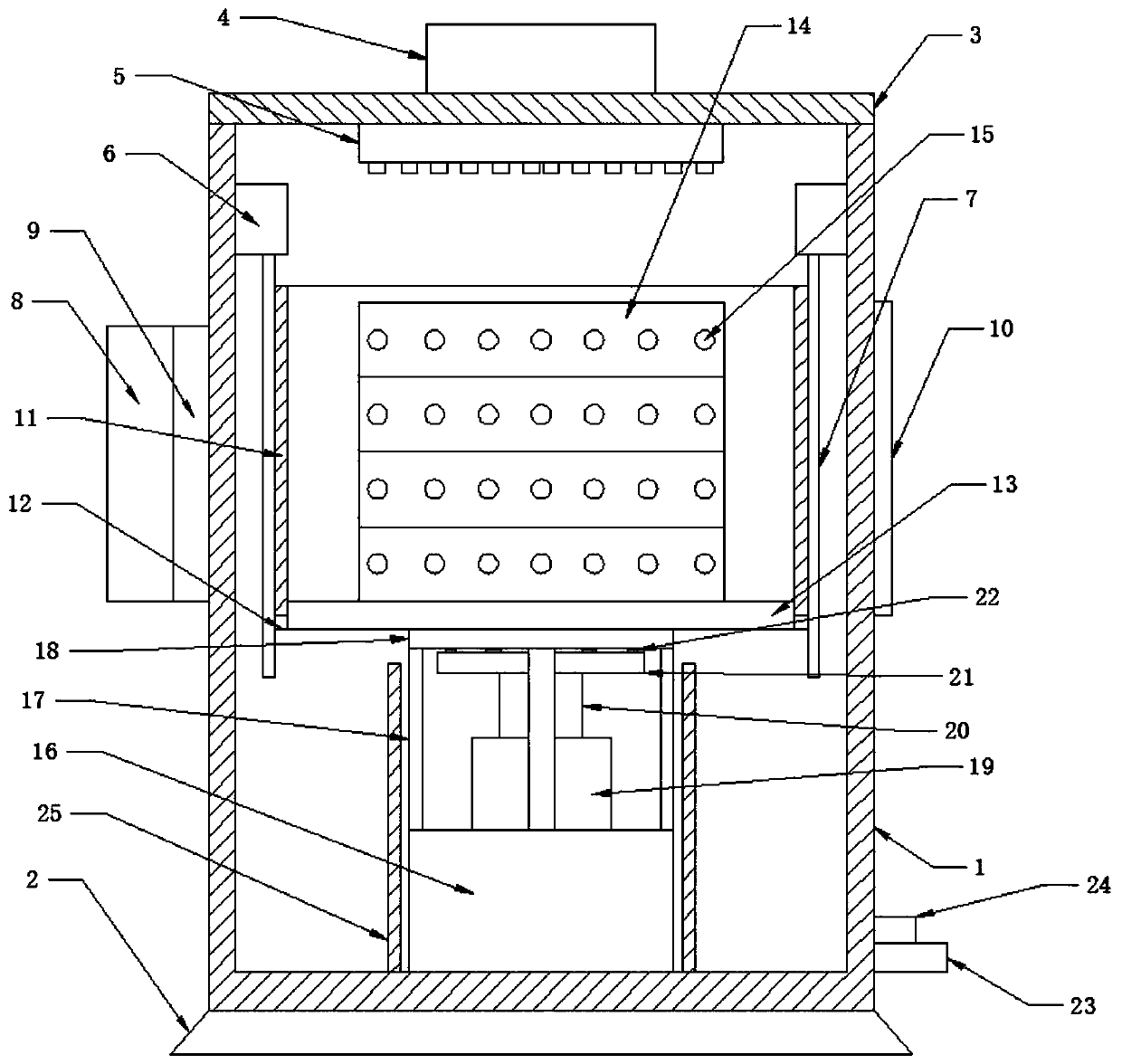

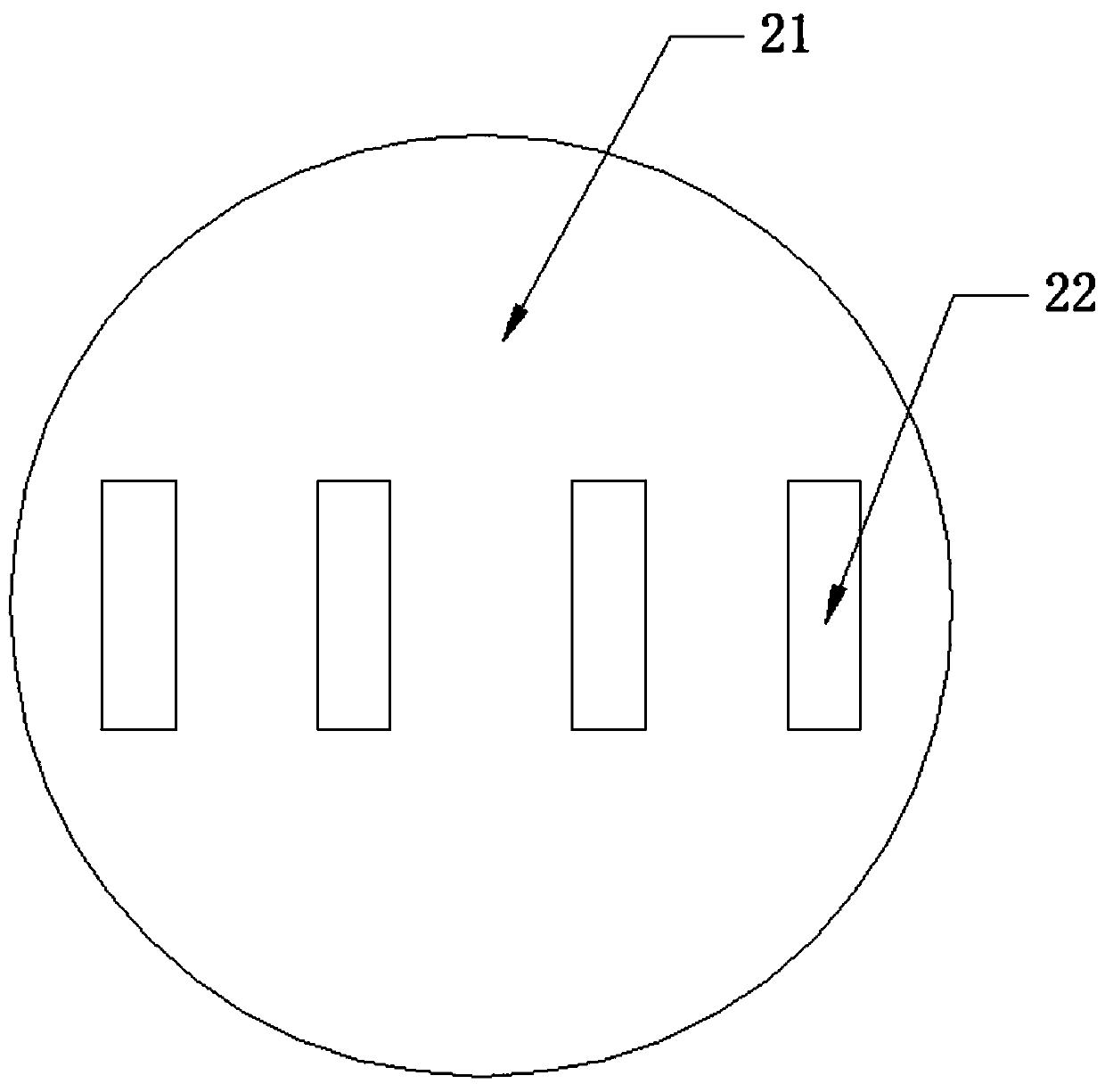

[0020] like figure 1 As shown in or 2, the present invention is a new type of fully automatic washing and drying integrated machine, including an integrated machine body 1, the integrated machine body 1 is a cylindrical tubular structure and a base 2 is installed at the bottom, and the center of the inner bottom of the integrated machine body 1 is A lifting motor 16 is installed at the top edge of the lifting motor 16. Several lifting support columns 17 are vertically installed at the output end of the top edge of the lifting motor 16. A support ring 18 is installed horizontally on the top of each lifting support column 17. A rotating ring 18 is installed at the center of the lifting motor 16 top. Motor 19, a support column 20 is installed at the output end of the top of the rotating motor 19, a rotating disc 21 is installed horizontally on the top of the supporting column 20, several blocks 22 are installed on the top of the rotating disc 21, and a cylindrical water barrier is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com