Supercooled water dynamic ice storage equipment and ice making method thereof

A technology for supercooled water and ice storage, which can be used in ice making, lighting and heating equipment, and ice manufacturing, etc. It can solve the problems of complex ice making, difficult control of ice storage technology, and easy ice blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

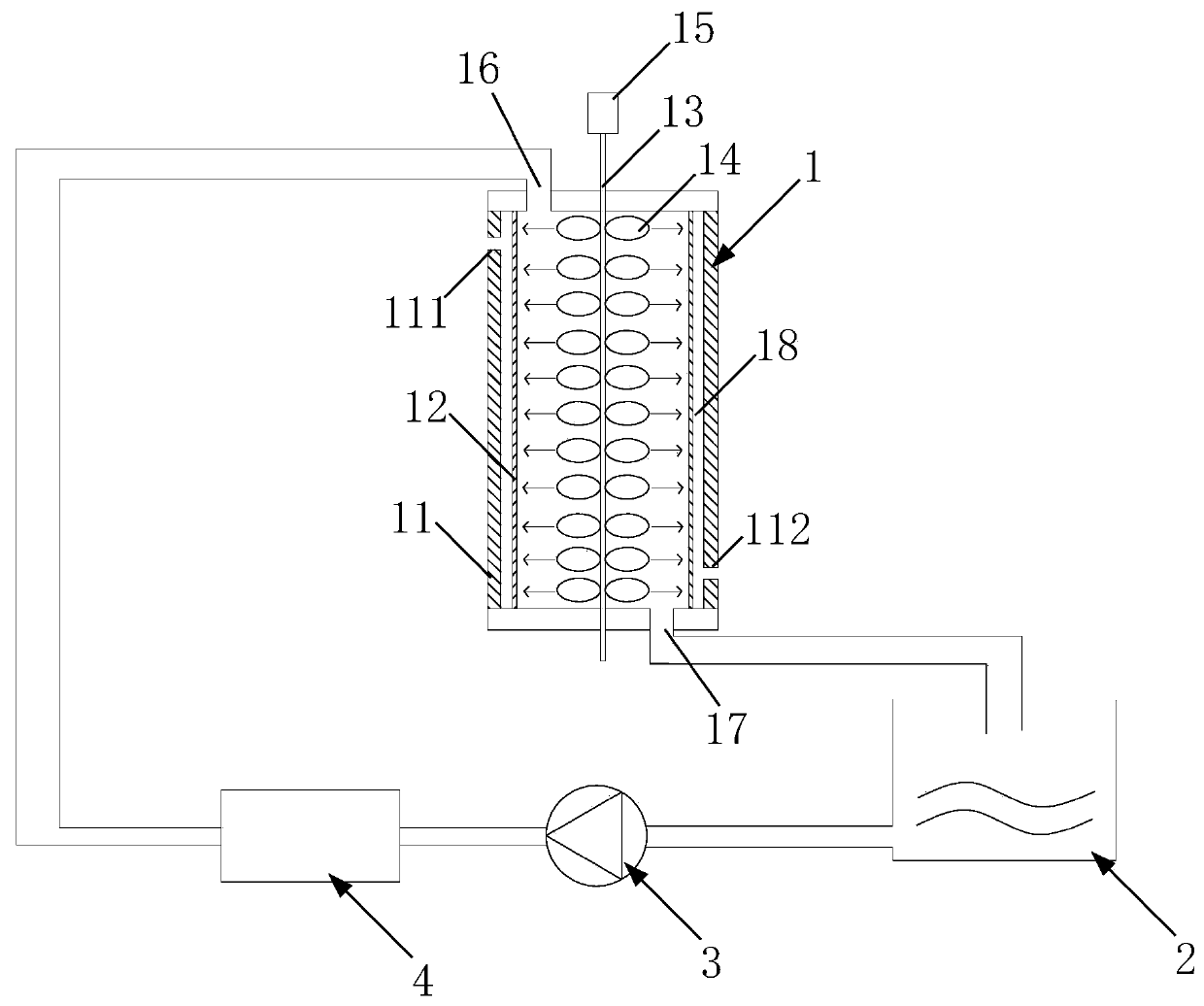

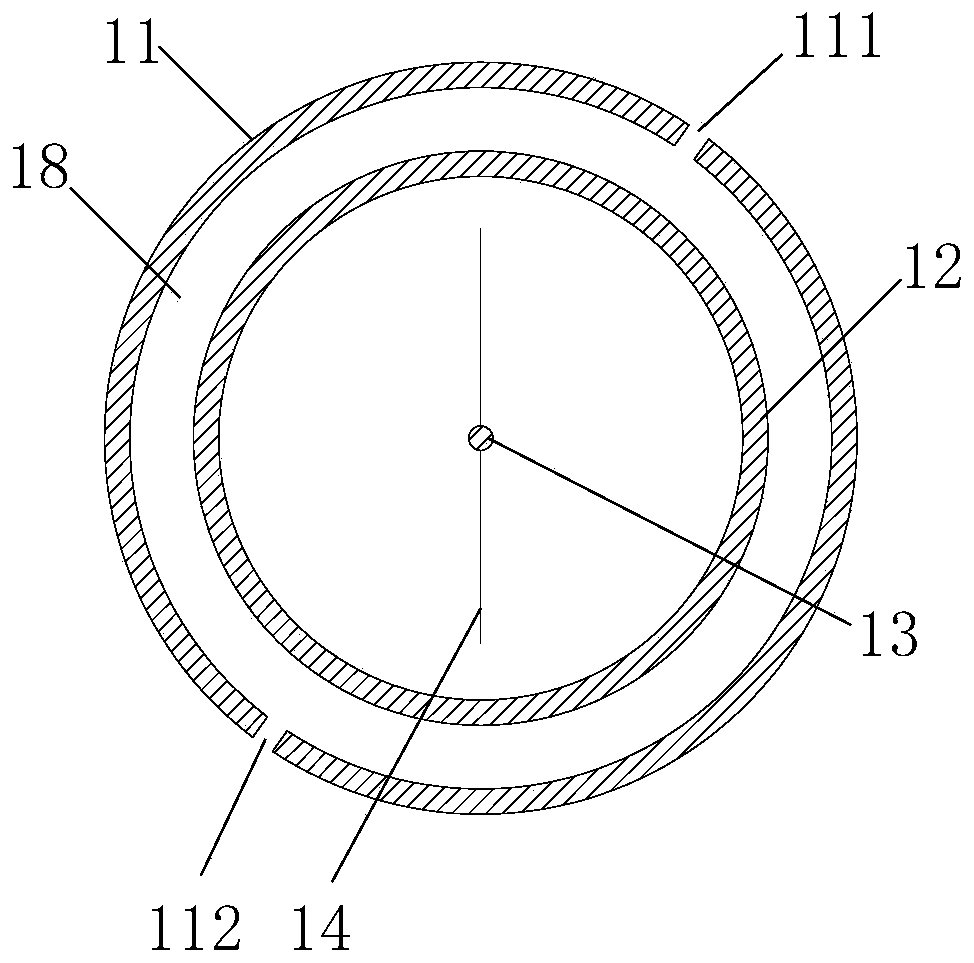

[0030] see figure 1 and image 3 As shown, a kind of supercooled water dynamic ice cold storage equipment includes a cold storage device, an ice storage tank 2, a water pump 3 and a filtering device 4 connected in pairs by pipelines. The cold storage device includes a refrigeration system and a vertical supercooler 1, The supercooler 1 communicates with the outside world through a water inlet 16 and a water outlet 17;

[0031] The supercooler 1 includes an outer cylinder 11, an inner cylinder 12 set inside the outer cylinder, a central transmission shaft 13 that runs through the axis of the outer cylinder 11 and the inner cylinder 12, and a multi-layered and each A layer of blades 14 uniformly distributed around the shaft and a rotating motor 15 connected to the central drive shaft.

[0032] There is a gap between the outer cylinder 11 and the inner cylinder 12 to form a cavity 18. The cylinder body of the outer cylinder is respectively pierced with a refrigerant inlet 111 a...

Embodiment 2

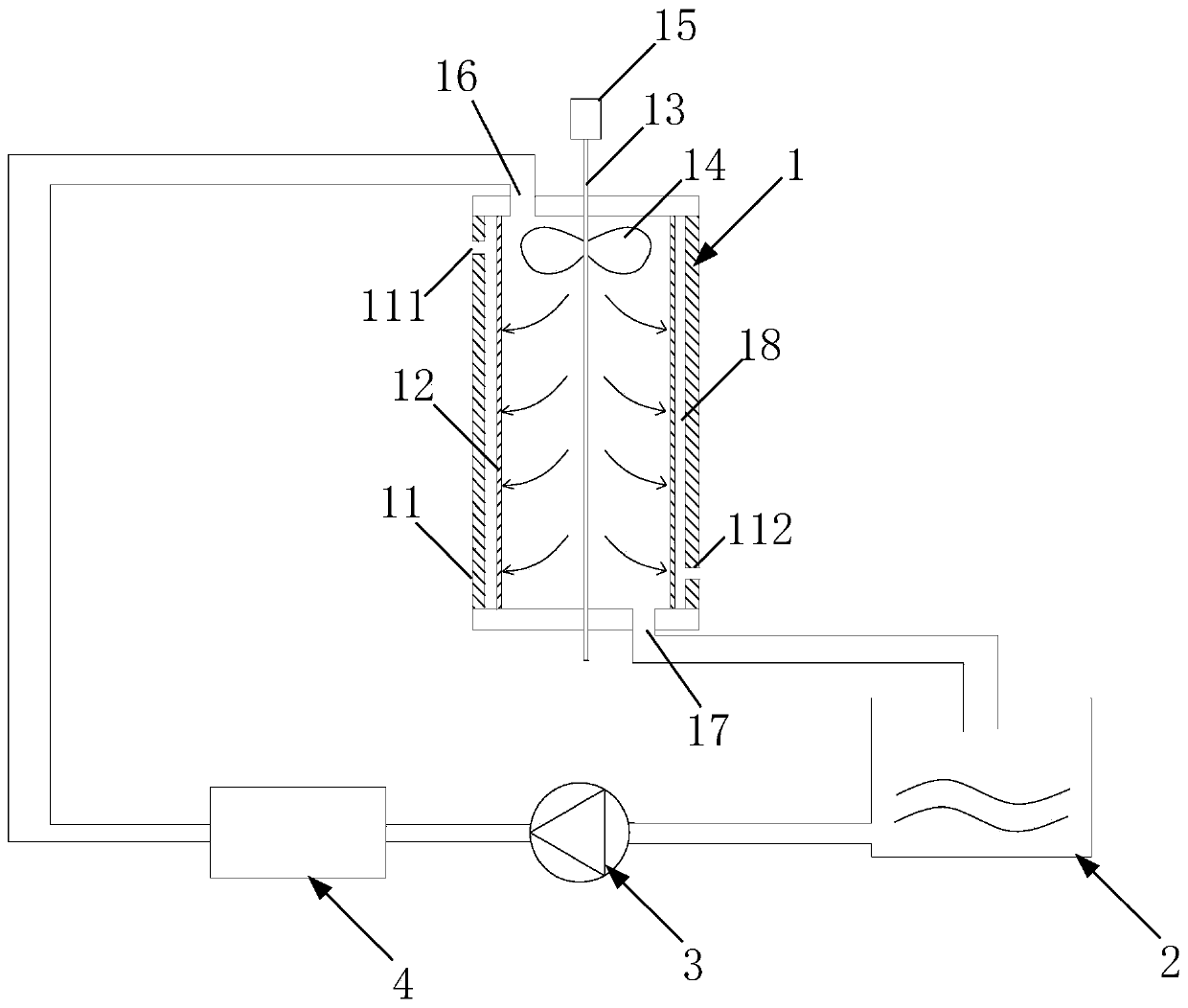

[0038] see figure 2 As mentioned above, the difference between the second embodiment and the first embodiment is that the blades 14 on the central transmission shaft 13 are set, and the end of the central transmission shaft 13 near the water outlet 17 is provided with a single layer of blades 14 evenly distributed around the shaft. .

[0039] The use of this type of blade can drive the water in the inner cylinder to undergo violent radial and axial turbulent movements. From the central transmission shaft to the inner wall of the inner cylinder, the closer to the inner wall of the inner cylinder, the more violent the water flow turbulence.

[0040] An ice making method for supercooled water dynamic ice storage equipment, specifically comprising the following steps:

[0041] (1) Add a certain concentration of solvent to the inner cylinder of the subcooler;

[0042] (2) The refrigeration system is started, and the supply refrigerant enters the cavity from the refrigerant inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com