Permanent magnet-free omnidirectional SH wave electromagnetic ultrasonic transducer and design method thereof

An electromagnetic ultrasonic and transducer technology, which is used in material analysis using sonic/ultrasonic/infrasonic waves, generation of ultrasonic/sonic/infrasonic waves, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the purpose, technical solution and advantages of the SH wave electromagnetic ultrasonic transducer clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

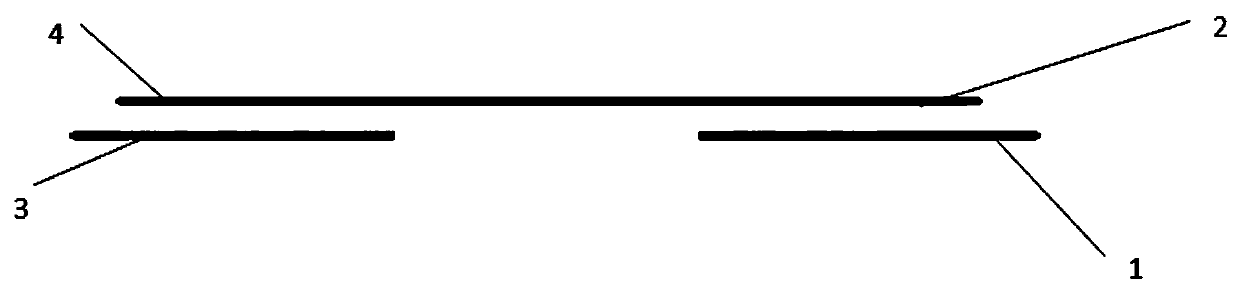

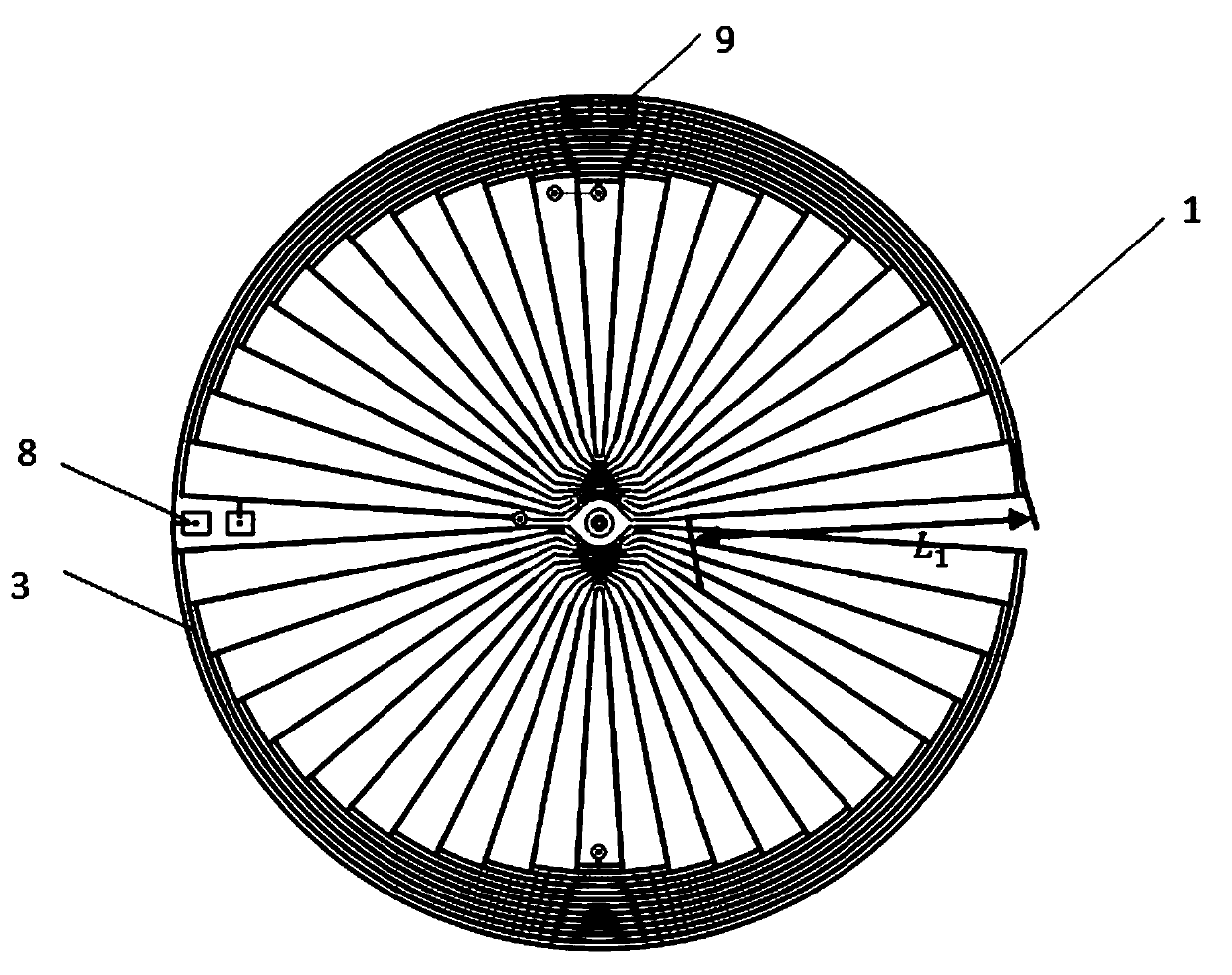

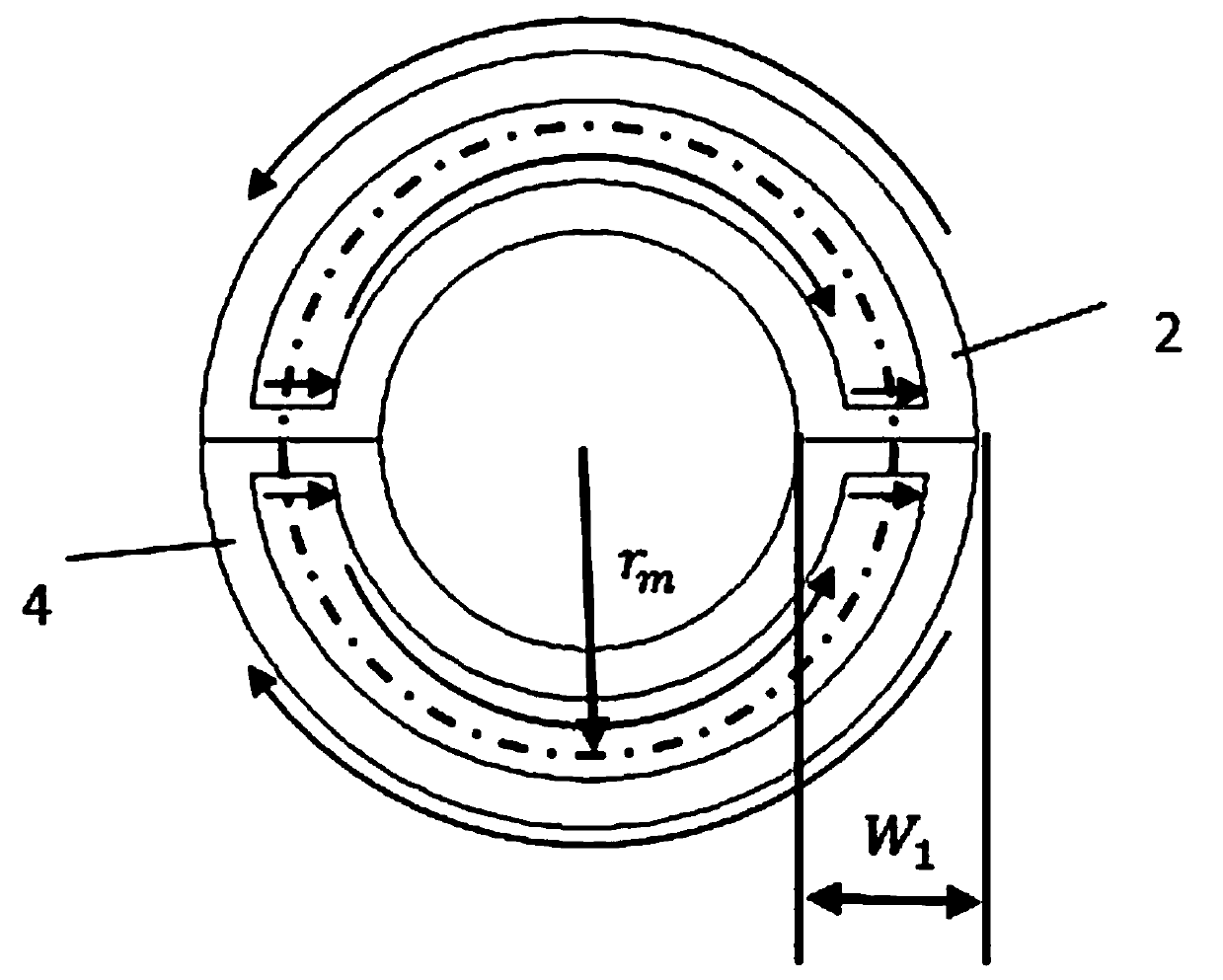

[0042] Such as figure 1 As shown, an omnidirectional SH wave electromagnetic ultrasonic transducer without permanent magnets is mainly composed of two parts of PCB coils, including excitation coils and electromagnetic field coils. The excitation coil can have two or more layers, but it must be an even number of layers. The whole coil is divided into upper and lower parts. The bottom layer wraps around from the inside out. The lower part is similar to the upper part. The wires coming out of the bottom layer are wound from the outside to the inside. The innermost ring is connected to the top layer with vias, and then wound from the inside of the top layer coil to the outside. The essence of the upper and lower parts of the coil is one. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com