Precursor of ternary material

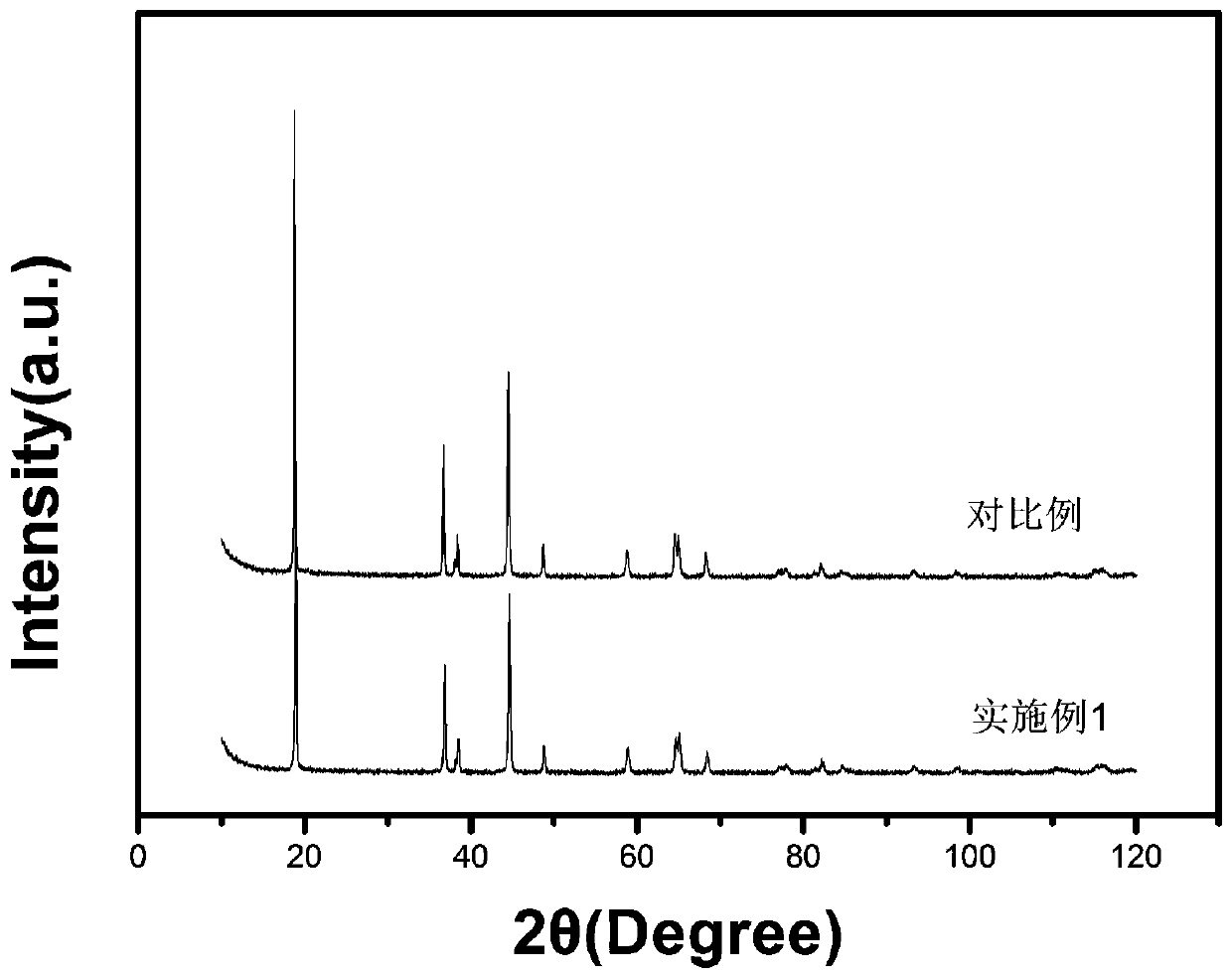

A technology of ternary materials and precursors, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of large differences in particle size distribution, which are not conducive to improving the rate performance of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

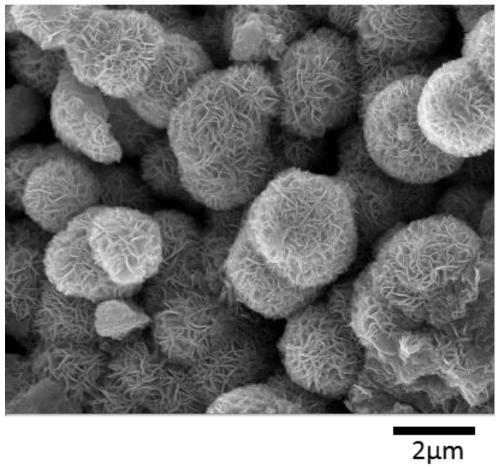

[0027] Add 0.3g of polyethylene glycol 4000 into 40ml of deionized water, stir magnetically for 30min until the solution is evenly mixed; then add 0.8mmol of nickel nitrate, 0.1mmol of cobalt nitrate and 0.1mmol of manganese nitrate into the solution, stir magnetically for 1h until clarification, turn to Put it into a 50ml reaction kettle, react at 150°C for 24h; filter and wash the reactant, and dry it in an oven at 60°C for 18h to obtain the flower-like structure Ni 0.8 mn 0.1 co 0.1 (OH) 2 Ternary material precursors. It looks like figure 1 Shown is a three-dimensional flower-like structure assembled from nanosheets.

Embodiment 2

[0033] Add 0.3g of polyethylene glycol 4000 into 40ml of deionized water, stir magnetically for 30min until the solution is evenly mixed; then add 0.333mmol of nickel nitrate, 0.333mmol of cobalt nitrate and 0.333mmol of manganese nitrate into the solution, stir magnetically for 1h until clarification, turn to into a 50ml reactor, and reacted at 180°C for 24h; the reactant was filtered and washed, and dried in an oven at 60°C for 18h to obtain a three-dimensional flower-like structure Ni 1 / 3 mn 1 / 3 co 1 / 3 (OH) 2 Ternary material precursors.

Embodiment 3

[0035] Add 0.4g of polyethylene glycol 4000 into 40ml of deionized water, stir magnetically for 30min until the solution is evenly mixed; then add 0.6mmol of nickel nitrate, 0.2mmol of cobalt nitrate and 0.2mmol of manganese nitrate into the solution, stir magnetically for 1h until clarification, turn to into a 50ml reactor, and reacted at 180°C for 24h; the reactant was filtered and washed, and dried in an oven at 60°C for 18h to obtain a three-dimensional flower-like structure Ni 0.6 mn 0.2 co 0.2 (OH) 2 Ternary material precursors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap