Mobile wall wiring structure

A wiring structure and mobile technology, applied in the direction of electrical components, etc., can solve the problems that the wall is not easy to handle, the installation depth of the junction box is inconsistent, and the beauty of the wall is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

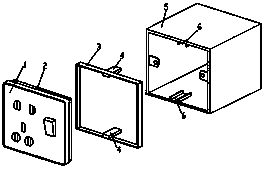

[0011] Embodiment 1: A mobile wall wiring structure, including a wall inner box 5 and an outer box frame 3; The inner side and the inner side below the wall inner box 5 are respectively provided with guide rails 6; 3. Inserting strips 4 adapted to guide rails 6 are respectively provided on the inner side of the bottom. The construction process of the adjustable wall junction bottom box is as follows: First, the wall inner box 5 is reinforced on the shear wall or column steel bars, and then the mold is closed to ensure that the edge of the wall inner box 5 is firmly attached to the formwork. After the concrete is poured and the formwork is removed, the residue around the inner box 5 of the wall is cleaned. If the concrete structure meets the requirements, then proceed directly to the later decoration construction, and then use the common wire box panel in the market for installation. If there is deviation in the concrete structure, when the wall or column surface needs to be ...

Embodiment 2

[0012] Embodiment 2: A mobile wall wiring structure, including a wall inner box 5 and an outer box frame 3; The inner side and the inner side below the wall inner box 5 are respectively provided with guide rails 6; 3. Inserting strips 4 adapted to guide rails 6 are respectively provided on the inner side of the bottom. The guide rails 6 are respectively arranged on the inner middle part above the wall inner box 5 and the inner middle part below the wall inner box 5; Medial middle. The construction process of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com