Remote control type hydraulic bracket communication system and method

A hydraulic support and communication system technology, applied in transmission systems, pillars/supports, digital transmission systems, etc., can solve problems such as no operation mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

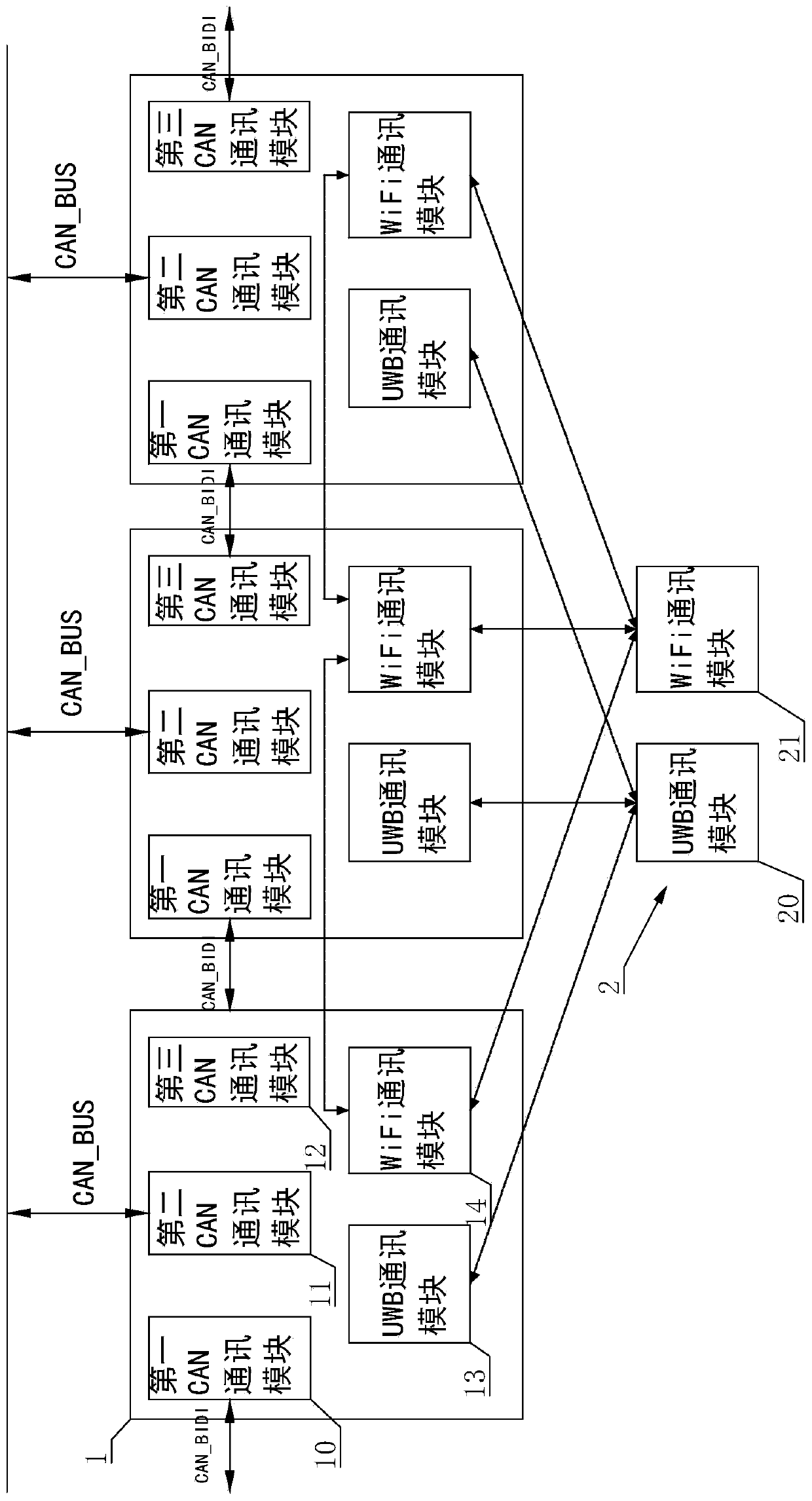

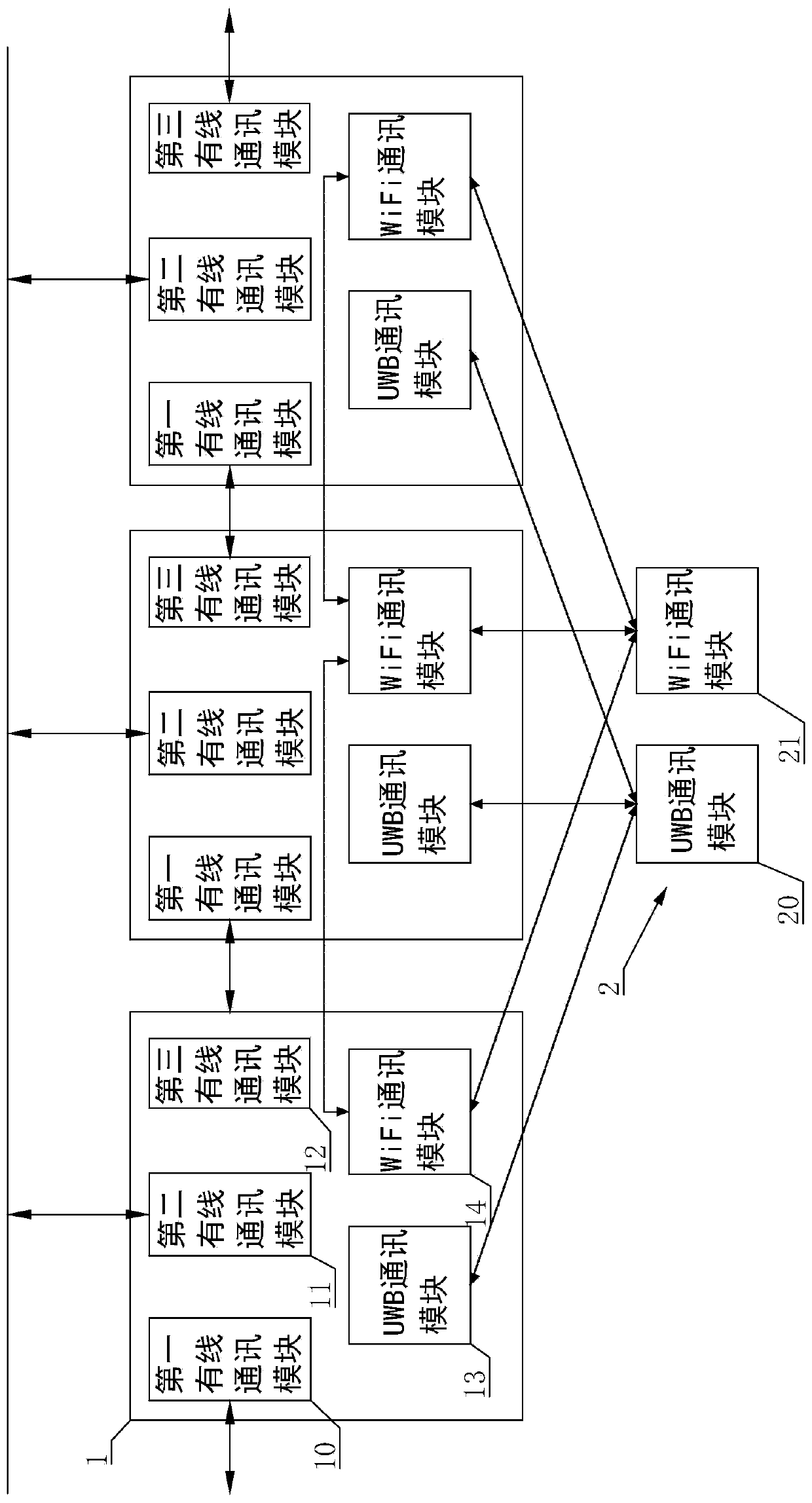

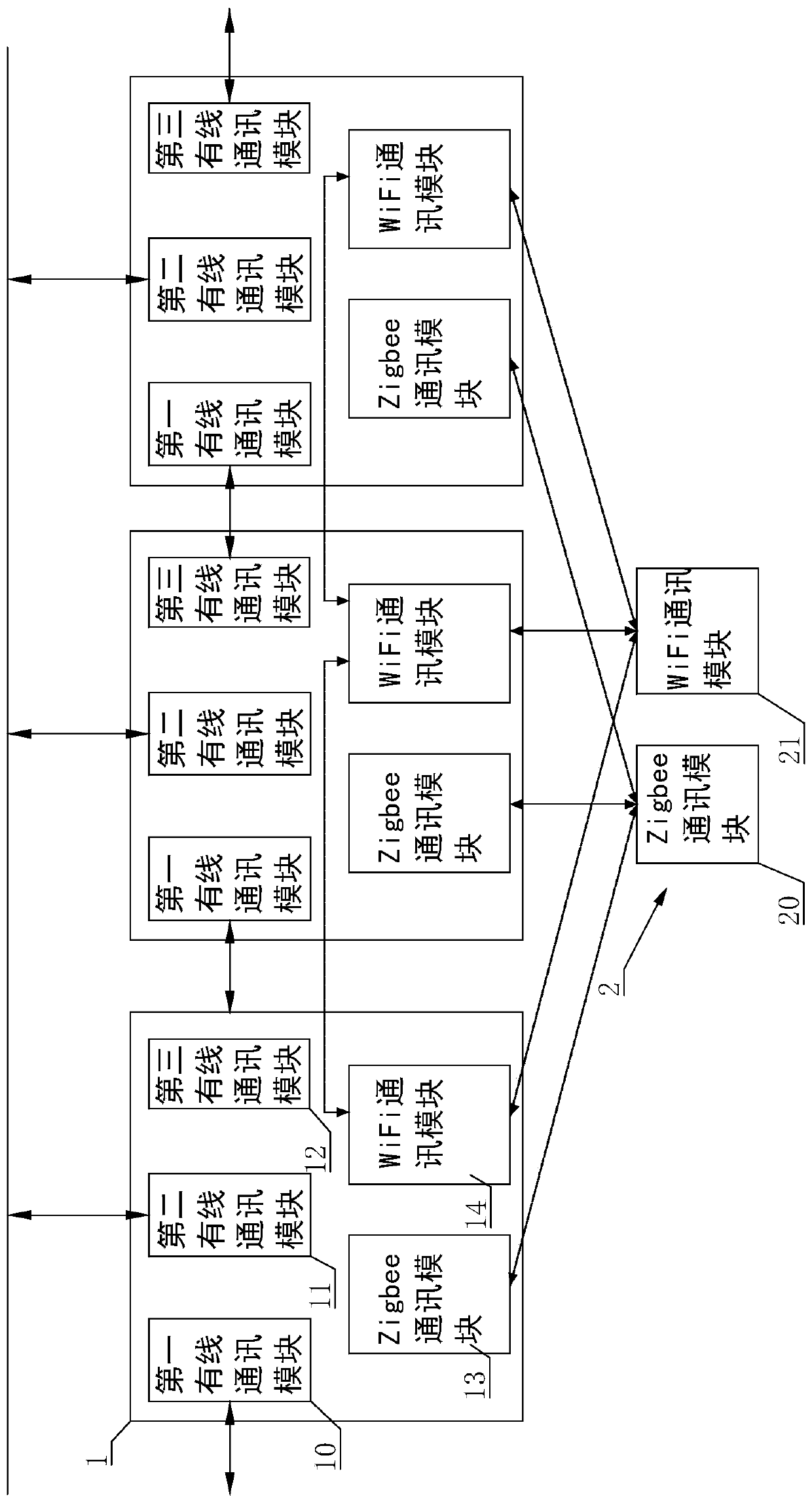

[0040] Such as Figure 1 to Figure 4 Commonly shown, a remote control type hydraulic support communication system includes multiple hydraulic supports, each hydraulic support is provided with a support controller, the support controller is provided with a first communication unit, and the first communication unit includes at least two wired Communication module and at least two wireless communication modules, each communication module of the first communication unit can carry out the communication between the support controllers on all hydraulic supports, forming multiple wired or wireless communication loops; the system also includes support remote control, support The remote controller is provided with a second communication unit. The second communication unit includes at least two wireless communication modules. The second communication unit and the first communication unit form at least two wireless communication loops for binding to establish a wireless connection to trans...

Embodiment 2

[0069] A remote-controlled hydraulic support communication method, based on the remote-controlled hydraulic support communication system in Embodiment 1;

[0070] Described method comprises the following steps:

[0071] Step 1. The support controllers on all hydraulic supports communicate through the wired communication module;

[0072] Step 2: The stand remote controller determines the stand controller closest to it, and binds with the stand controller within a preset time to establish a wireless connection;

[0073] Step 3: Enter the locked state under the control of the bound bracket controller;

[0074] Step 4. After binding, the bracket remote controller transmits data through the wireless communication circuit between the second communication unit and the first communication unit;

[0075] Step 5. The bound support controller transmits data to the selected support controller of the hydraulic support through the wired communication module. When the data transmission fai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com