Method for enzymatically producing bioethanol using cellulosic biomass as starting material

A technology of bioethanol and a production method, which is applied in the field of producing ethanol and can solve problems such as load increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

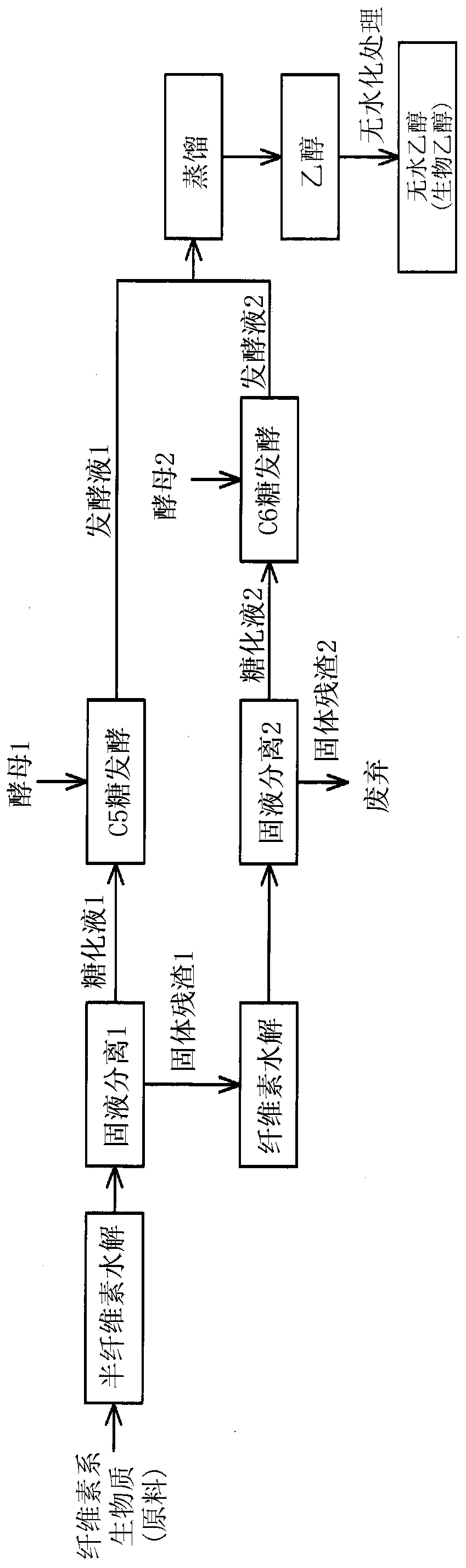

Method used

Image

Examples

Embodiment approach 1

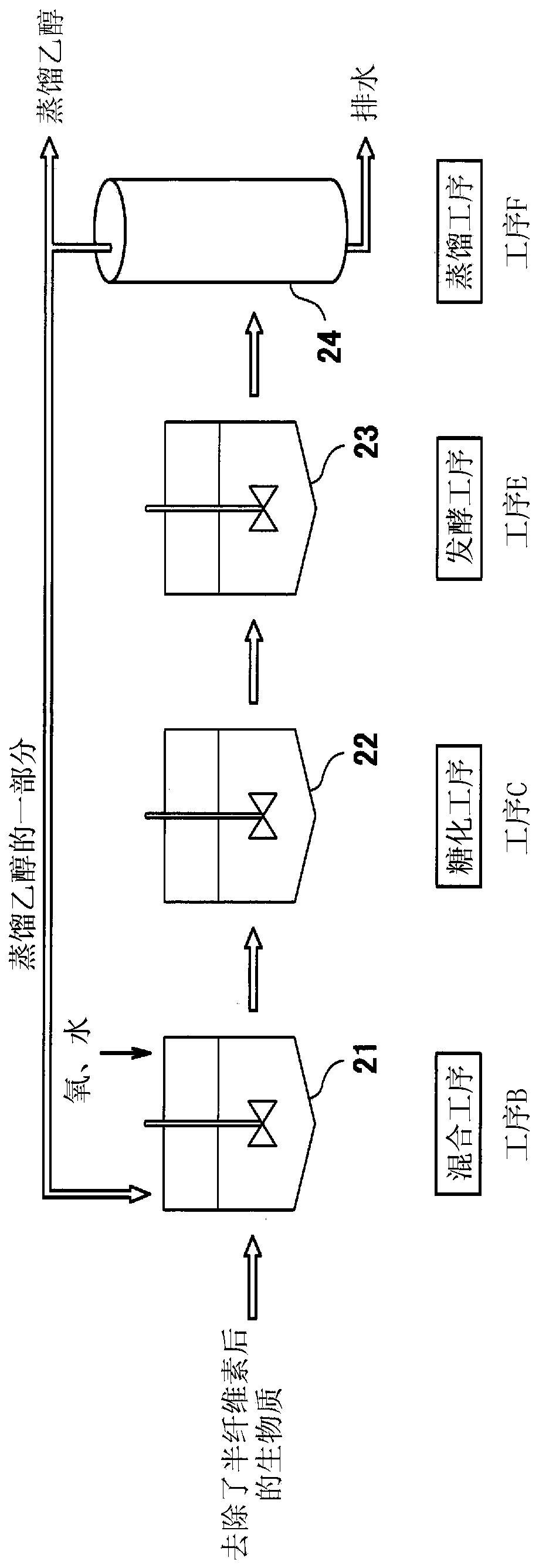

[0086] image 3 A diagram illustrating the ethanol production method of Embodiment 1 is shown. In the method for producing ethanol according to Embodiment 1, steps B to E are implemented in the mixing tank 21 , the saccharification tank 22 , and the fermentation tank 23 , respectively. In a steady state, a part of the distilled ethanol obtained from the distillation apparatus 24 is supplied to the tank 21 in which the step B is carried out. The added distilled ethanol is then recovered by the distillation unit 24 .

Embodiment approach 2

[0088] Figure 4 A figure explaining the ethanol production method of Embodiment 2 is shown. The ethanol production method of Embodiment 2 is the same as Embodiment 1 except that Step C (saccharification step) and Step E (fermentation step) are continuously performed in one tank (saccharification fermentation tank 32 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com