Thermistor sintered body and temperature sensor element

A technology of thermistors and heat-sensitive elements, which is applied in the direction of resistors, electrical elements, and thermometers using electric/magnetic elements that are directly sensitive to heat, and can solve problems such as inability to detect temperature correctly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] Next, the thermistor sintered body of the present invention will be described based on examples.

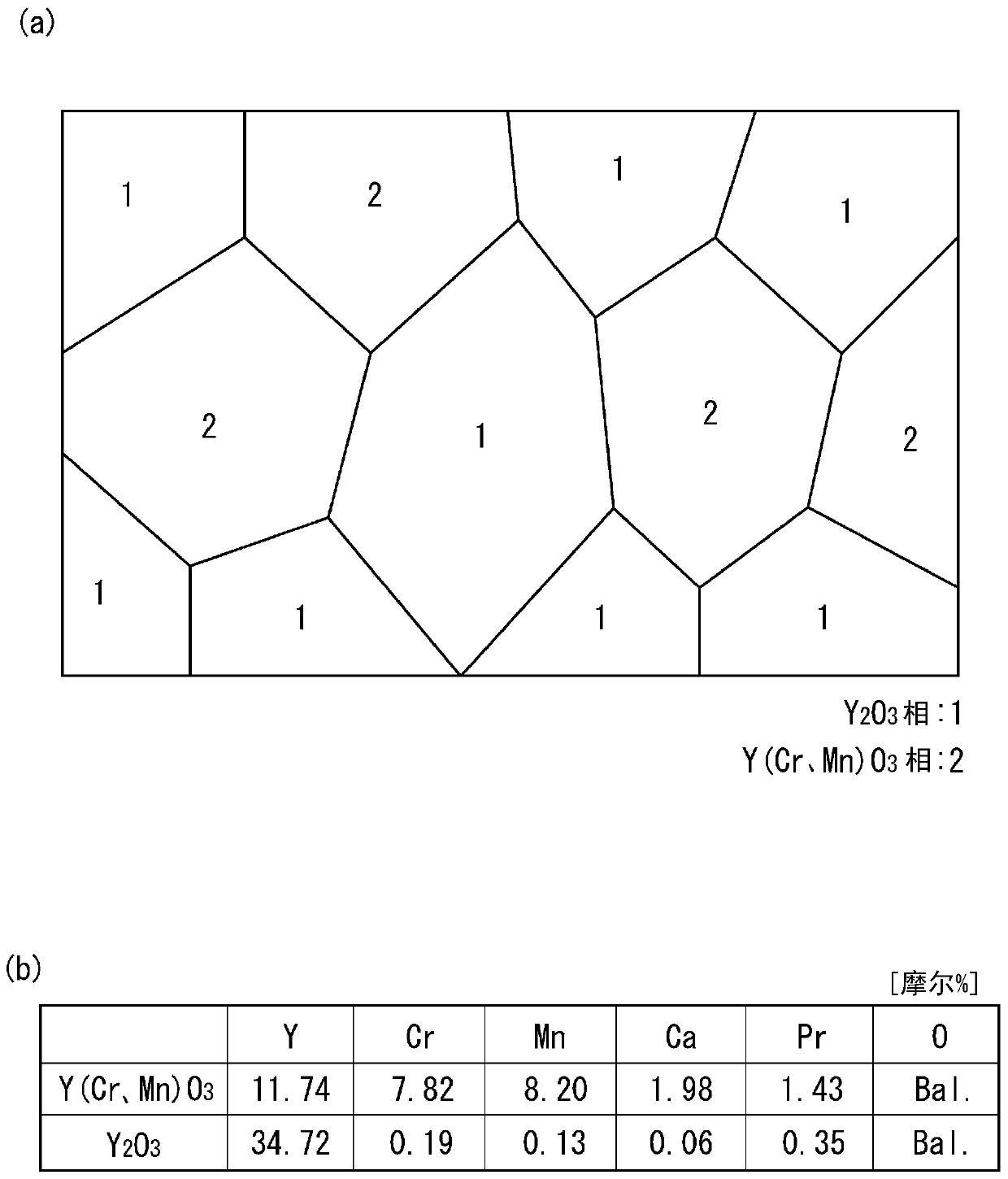

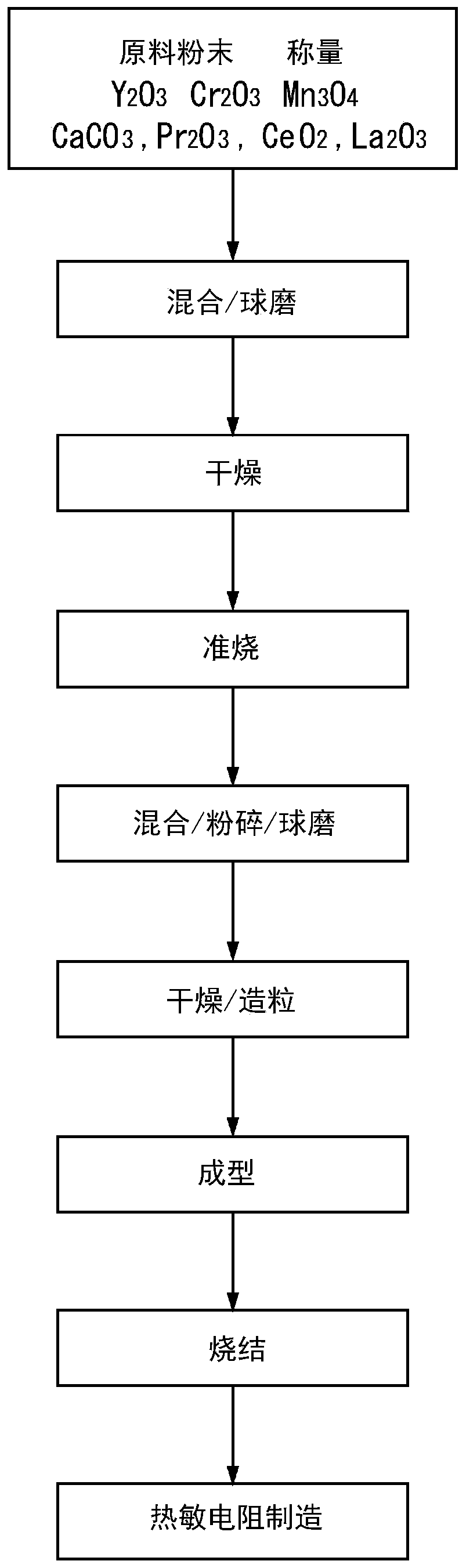

[0107] Prepare the raw material powder with the following average particle size, according to the above-mentioned production process, produced the powder with Figure 5 Thermistor sintered bodies of various compositions shown in . These thermistor sintered body in Y(Cr, Mn)O 3 Both Cr and Mn are contained in a phase. In this table, No.1 represents the basic composition in this example that does not contain rare earths other than Y, Nos.2 to 5 are samples containing Pr, Nos.6 to 9 are samples containing Y, and Nos. Nos. 10 to 13 are samples containing La, and Nos. 14 to 17 are samples containing Ce.

[0108] For the sample, pre-firing was set at 1000° C. for 24 hours, and sintering was set at 1500° C. for 24 hours, and both were performed in the air.

[0109] Y 2 o 3 Powder: 0.1μm Pr 2 o 3 Powder: 0.1μm La 2 o 3 Powder: 0.1μm

[0110] CeO 2 Powder: 0.1μm Cr 2 o...

Embodiment 2

[0116] Next, make a Figure 7 Thermistor sintered bodies of various compositions shown in . The raw material powder used and the manufacturing process are the same as in Example 1. exist Figure 7 Among them, Group A and Group B contain Y(Cr, Mn)O as in Example 1. 3 Phase is the thermistor sintered body as the subphase, but the basic chemical composition other than Pr is different from that of Example 1. In addition, in Figure 7 Among them, Group C contains YCrO 3 phase as the secondary phase of the thermistor sintered body.

[0117] For each of the obtained sintered bodies, the B constant was determined in the same manner as in Example 1. show the result in Figure 8 (group A), Figure 9 (Group B) and Figure 10 (Group C).

[0118] Such as Figure 8 and Figure 9 As shown in , containing Pr and Y(Cr,Mn)O 3 The thermistor sintered body whose phase constitutes the secondary phase has a small change in the B constant with respect to the amount of increase in the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com