Metallurgical machinery equipment capable of automatically screening ore

A kind of mechanical equipment and automatic screen technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of weight mechanical burden, increased cost expenditure, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

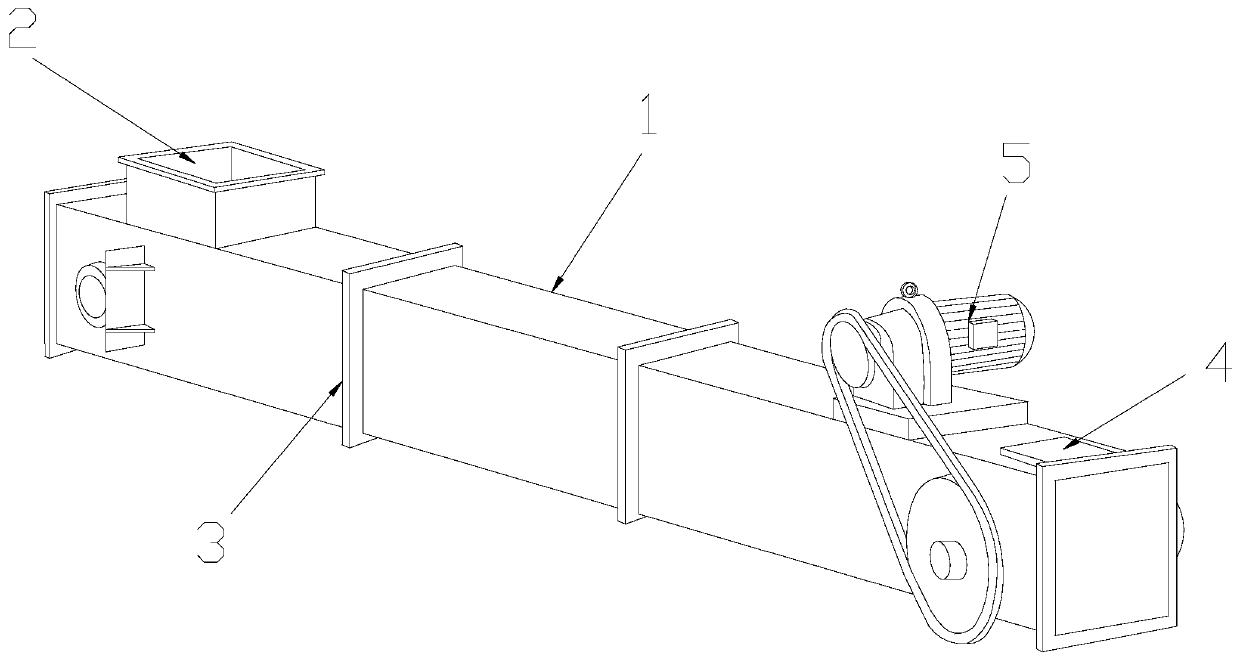

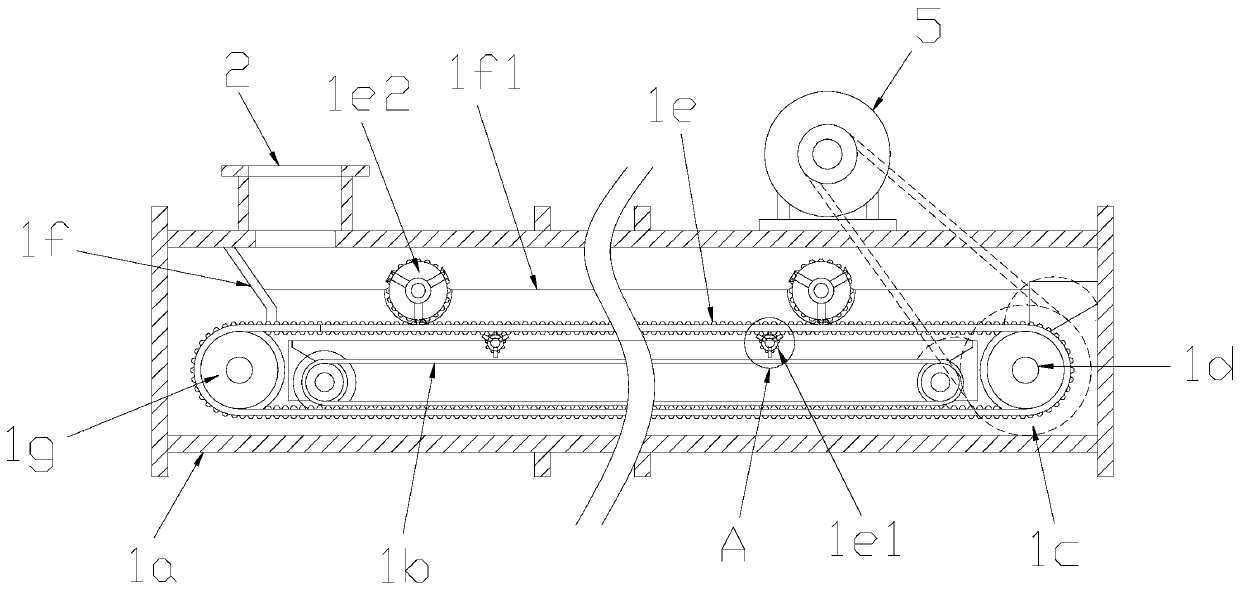

[0030] see Figure 1-Figure 6 , the present invention provides a metallurgical mechanical equipment that can automatically screen ore, and its structure includes a bulk material conveying equipment 1, a material inlet 2, a support frame 3, a maintenance cover 4, and a power unit 5. The top end of the bulk material conveying equipment 1 There is a material inlet 2 on the surface, and more than two support frames 3 are provided on the surface of the bulk material conveying equipment 1. The bulk material conveying equipment 1 and the support frames 3 are an integrated structure. A power unit 5 is provided on the top of the material conveying equipment 1, the bulk material conveying equipment 1 is connected to the power unit 5, a maintenance cover 4 is provided on the top of the bulk material conveying equipment 1, and the bulk material conveying equipment 1 and the maintenance cover 4 are connected by hinges;

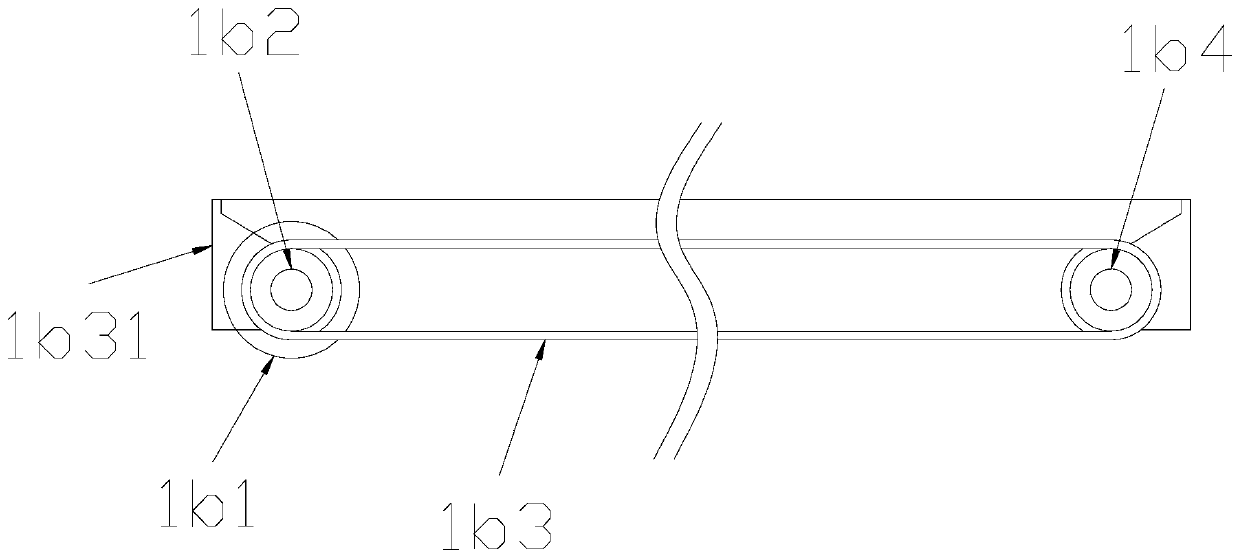

[0031] The bulk material conveying equipment 1 is composed of a body...

Embodiment 2

[0040] see Figure 1-Figure 7 , the present invention provides a metallurgical mechanical equipment that can automatically screen ore. The sweeping mechanism 1e2 is composed of a second gear plate 1e21, a second rotating shaft 1e22, a sweeping plate 1e23, and a shovel bar 1e24. The second rotating shaft There is a second gear disc 1e21 on the left and right ends of 1e22, the second rotating shaft 1e22 is connected with the second gear disc 1e21, the surface of the second rotating shaft 1e22 is provided with a sweeping plate 1e23, and the second rotating shaft 1e22 is provided with a sweeping plate 1e23. The rotating shaft 1e22 is fixedly connected to one end of the sweeping plate 1e23, and the other end of the sweeping plate 1e23 is provided with a shovel 1e24, and the sweeping plate 1e23 is glued to the shovel 1e24.

[0041] Two side leakage baffles 1f1 are arranged on the surface of the inclined material guide plate 1f, the inclined material guide plate 1f and the side leaka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com