A kind of preparation method and application of ginger oleoresin microcapsule

A technology of ginger oleoresin and microcapsules, which is applied in the field of daily chemicals, can solve problems that have not been well solved, and achieve the effect of simple preparation method and broad market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

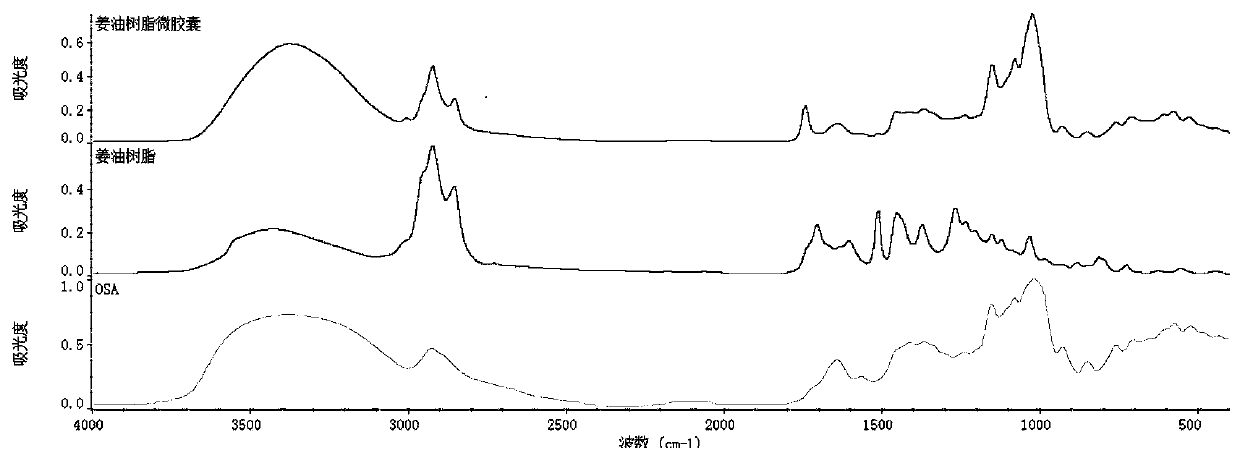

[0031] Embodiment 1 The preparation of ginger oleoresin microcapsules of the present invention

[0032] It includes the following steps: (1) dissolving OSA starch in water, hydrating for 12 hours, and overnight to make a uniform and stable wall material solution; (2) adding ginger oleoresin to soybean oil in a ratio of 1:1 to disperse 2 (3) mix soybean oil and OSA starch aqueous solution having ginger oleoresin by 1:5, stir 2min under the condition of 250rad / min to mix evenly with the mixer, under room temperature condition, use the homogenizer to Rotating speed, emulsification 5min, form pale yellow emulsion; (4) spray drying under the condition of 170 ℃ of inlet air temperature, 80 ℃ of outlet air temperature, feed speed 5ml / min, obtain the required ginger oleoresin microcapsules.

[0033] The embedding rate of ginger oleoresin microcapsules obtained in the experiment was 92%, and the yield was 85.97%.

Embodiment 2

[0034] Embodiment 2 The preparation of ginger oleoresin microcapsules of the present invention

[0035]It includes the following steps: (1) Dissolving OSA starch in water, hydrating for 5 hours, and overnight to make a uniform and stable wall material solution; (2) Adding ginger oleoresin to white oil in a ratio of 1:4 to disperse 3 (3) mix the white oil and the OSA starch aqueous solution that are dissolved with ginger oleoresin by 1:9, stir 2min to mix evenly under the condition of 250rad / min with the stirrer, under the room temperature condition, with the homogenizer with the speed of 20000r / min Rotating speed, emulsification 5min, form pale yellow emulsion; (4) spray drying under the condition of 170 ℃ of inlet air temperature, 80 ℃ of outlet air temperature, feed speed 5ml / min, obtain the required ginger oleoresin microcapsules.

[0036] The embedding rate of ginger oleoresin microcapsules obtained in the experiment was 85.5%, and the yield was 81%.

Embodiment 3

[0037] Embodiment 3 Preparation of ginger oleoresin microcapsules of the present invention

[0038] It includes the following steps: (1) Dissolving OSA starch in water, hydrating for 15 hours, and overnight to make a uniform and stable wall material solution; (2) Adding ginger oleoresin to white oil in a ratio of 1:4 to disperse 3 (3) mix the white oil and the OSA starch aqueous solution that are dissolved with ginger oleoresin by 1:9, stir 2min to mix evenly under the condition of 250rad / min with the stirrer, under the room temperature condition, with the homogenizer with the speed of 24000r / min Rotating speed, emulsification 3min, form pale yellow emulsion; (4) spray drying under the condition of 170 ℃ of inlet air temperature, 80 ℃ of outlet air temperature, feed speed 5ml / min, obtain the required ginger oleoresin microcapsules.

[0039] The embedding rate of ginger oleoresin microcapsules obtained in the experiment was 91.1%, and the yield was 84.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com