Raw material manufacturing processing system for water permeable brick preparation

A processing system and raw material technology, applied in the field of raw material processing and processing systems for the preparation of permeable bricks, can solve the problems of increasing processing costs and waste of resources, and achieve the effects of improving utilization, increasing movement paths, and increasing drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

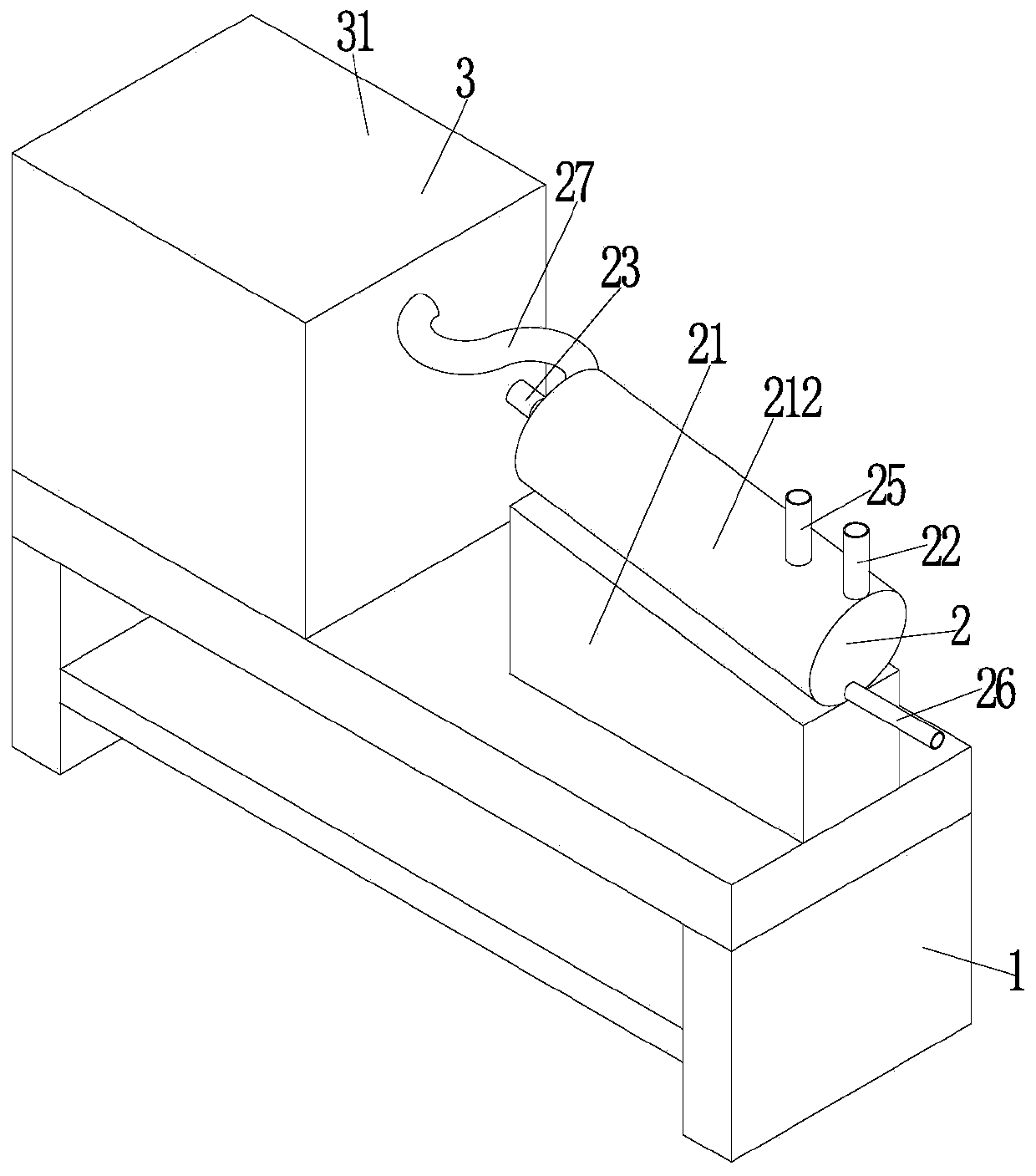

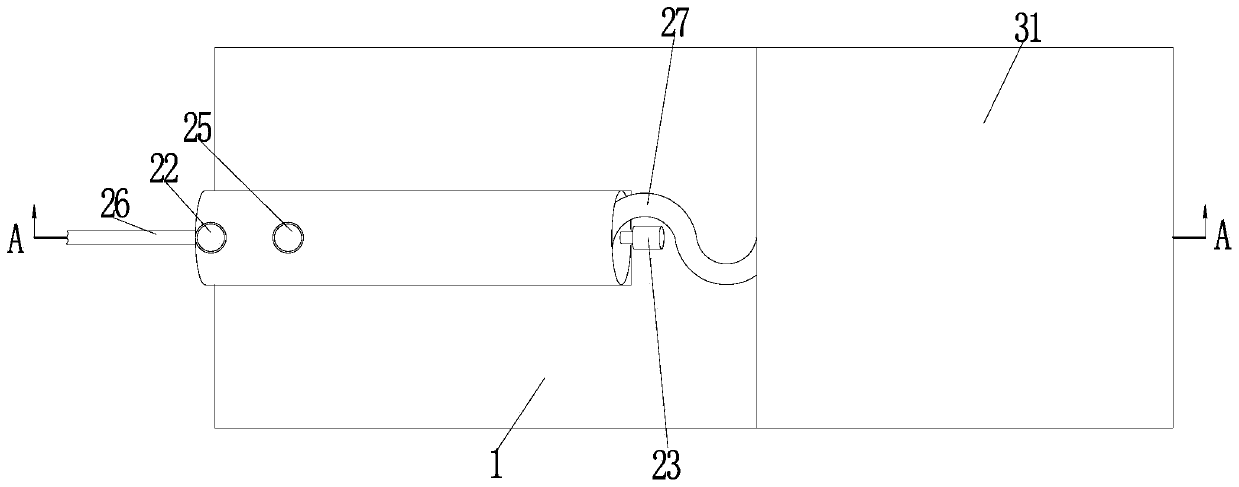

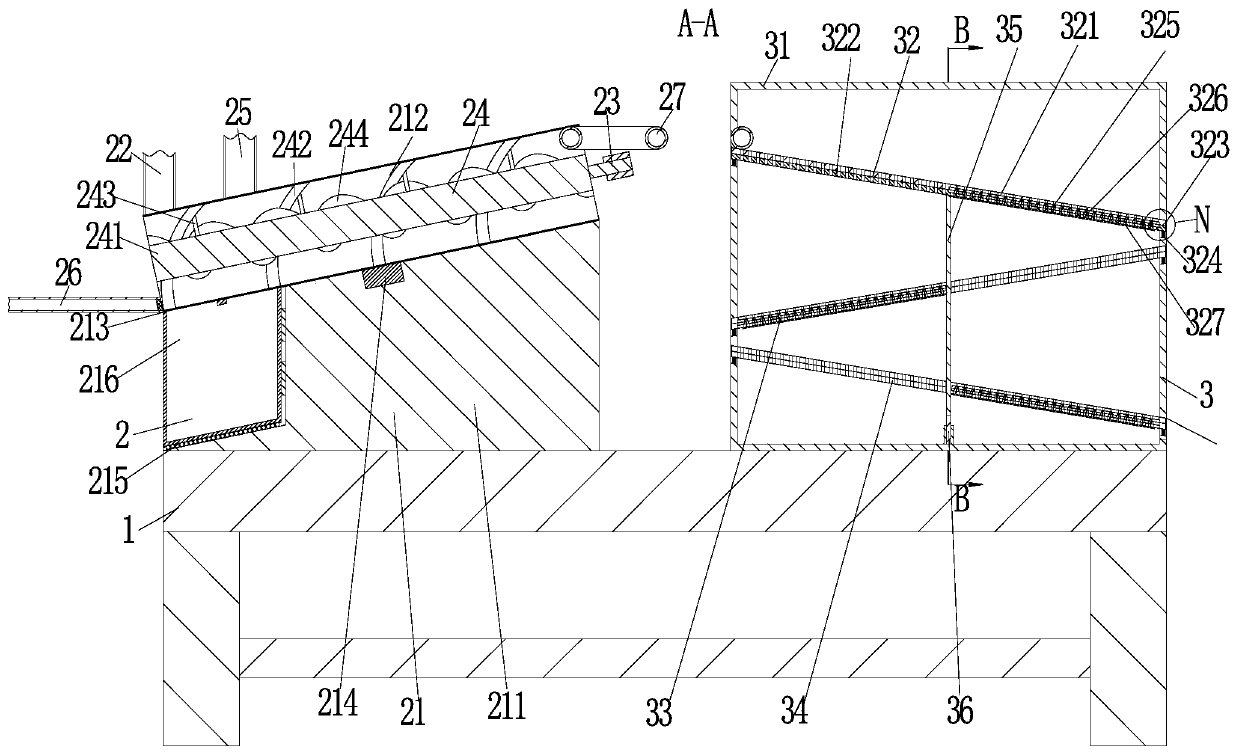

[0029] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 5 , to further elaborate the present invention.

[0030]A raw material processing system for preparing permeable bricks, comprising a workbench 1, a cleaning device 2 and a screening device 3, the cleaning device 2 is fixedly installed on the upper left side of the workbench 1, and the screening device 3 is installed on the right end of the cleaning device 2; The cleaning device 2 includes a cleaning frame 21, an input pipe 22, a motor 23, a screw frame 24, a water pipe 25, a water outlet pipe 26 and an output pipe 27. The upper end surface on the left side of the workbench 1 is fixed with a cleaning frame 21. The upper end of the side is equipped with an input pipe 22, and the right end of the cleaning rack 21 is fixed with a motor 23 through the motor 23 seat, and the output shaft of the left end...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap