A metal pipe rapid correction processing equipment

A technology for metal pipes and processing equipment, applied in metal processing equipment, safety equipment, feeding devices, etc., can solve the problems of time-consuming operation, affecting the overall quality of the building, and consuming a lot of energy, and achieves excellent correction results, which is conducive to popularization and use. Improve the effect of calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

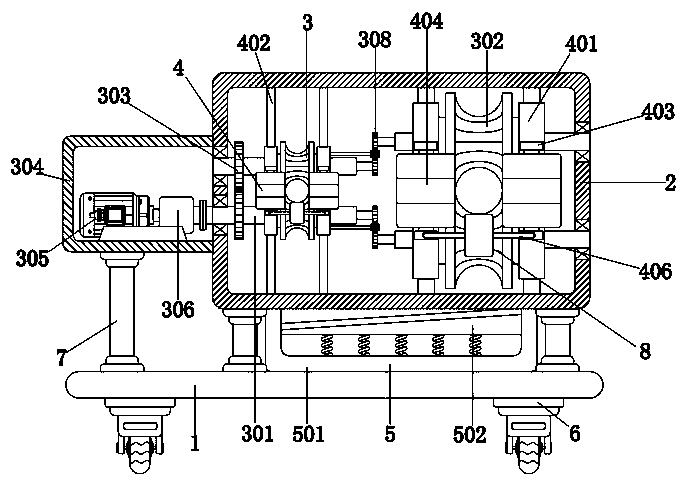

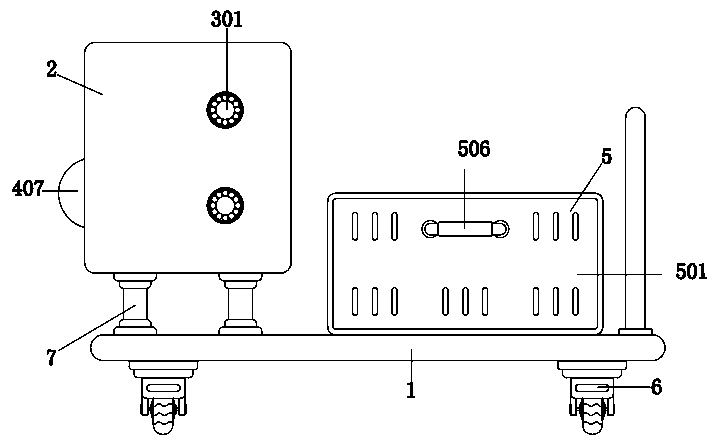

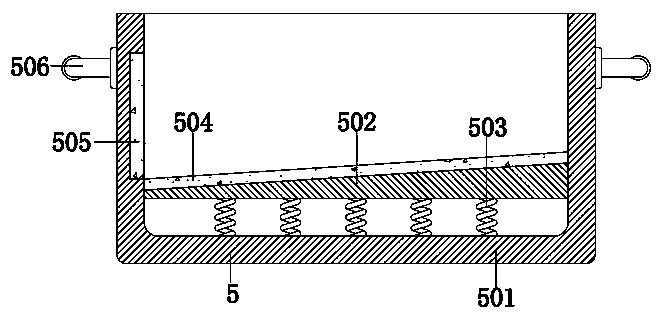

[0033]A metal pipe rapid straightening processing equipment, comprising a bottom plate 1, a box body 2 is arranged in front of the upper surface of the bottom plate 1, a straightening mechanism 3 is arranged inside the box body 2, universal wheels 6 are fixedly connected to the four corners of the bottom surface of the bottom plate 1, The universal wheel 6 is a universal wheel with a self-locking function, and the correction mechanism 3 includes a transverse shaft 301, a semicircular arc sheave 302, a first gear 303, a casing 304, a motor 305, a speed reducer 306, a base 307, The second gear 308, the tooth column 309 and the cross bar 310, a plurality of cross shafts 301 are respectively rotatably connected to the left and right sides of the inner wall of the box body 2, and the cross shaft 301 is connected to the case body 2 through ball bearings for rotation, and the outer wall of the cross shaft 301 The center is fixedly sleeved with a semi-arc sheave 302, and the upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com