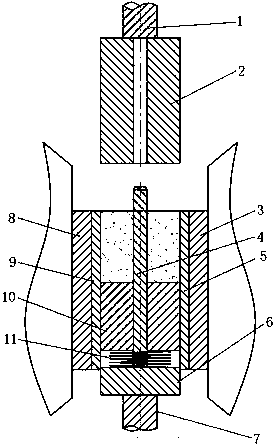

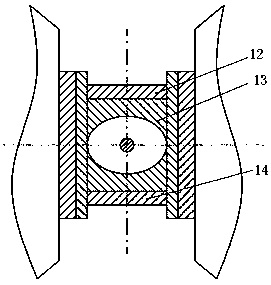

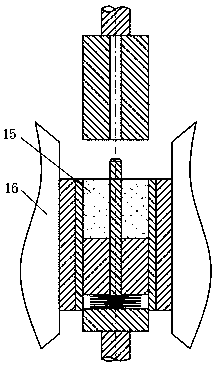

Forming die and method for preparing high-performance radial neodymium-iron-boron magnet

A technology for forming molds and radial rings, which is applied in metal processing equipment, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of material waste in the inner hole, low actual pass rate, and affect the concentricity of the inner hole, etc., to achieve Improve fluidity and eliminate the effect of orientation field difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) The industrial pure metal raw materials are weighed and proportioned according to the composition of the NdFeB alloy by weight percentage, and the composition mass percentage of the NdFeB alloy is (PrNd 1-x RE x ) a Fe bal Al b Cu c m d co e B f , where a=30%; where RE uses Dy element, x=0.025; b=0.4%; c=0.2%; e=1%, f=0.92%; where d=0.3%, M is Ti element 0.1% , Ga element 0.12%; R-Fe-B-M alloy coarse powder was obtained by cast sheet-hydrogen crushing process; 2) The prepared coarse powder was added to the polymer dispersant to homogenize and stir; 3) Step 2) prepared The obtained powder is jet milled to obtain a fine powder with a particle size of 2.4-8.5um; 4) The prepared fine powder is subjected to three-dimensional mixing and mixing treatment, and a spraying method is used during the three-dimensional mixing, and a mixed liquid additive is evenly added to improve the fine powder. Formability and fluidity; the monomer concentration of solvent oil is 50g / 1...

Embodiment 2

[0066] 1) The industrial pure metal raw materials are weighed and proportioned according to the composition of the NdFeB alloy by weight percentage, and the composition mass percentage of the NdFeB alloy is (PrNd 1-x RE x ) a Fe bal Al b Cu c m d co e B f , where a=30%; where RE uses Dy element, x=0.025; b=0.4%; c=0.2%; e=1%, f=0.92%; where d=0.3%, M is Ti element 0.1% , Ga element 0.12%; R-Fe-B-M alloy coarse powder was obtained by the casting-hydrogen crushing process; 2) The coarse powder obtained in step 1) was added to the polymer dispersant to homogenize and stir; 3) the step 2) The prepared powder is jet milled to obtain a fine powder with a particle size of 2.4-8.5um; 4) The fine powder obtained in step 3) is subjected to three-dimensional stirring and mixing treatment, and the three-dimensional stirring is performed by spraying, and the solvent is evenly added A liquid mixed additive composed of oil, dispersant, low molecular polymer antioxidant, release agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap