A composite brazing filler metal for superhard abrasive brazing, its preparation method, and brazing method

A technology of composite solder and superabrasives, applied in welding equipment, grinding/polishing equipment, grinding devices, etc., can solve the problems of low bond strength between diamond and matrix, easy shedding of diamond tools, and poor diamond grinding performance. Good and other problems, to achieve the effect of excellent grinding performance, good bonding strength, and excellent product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

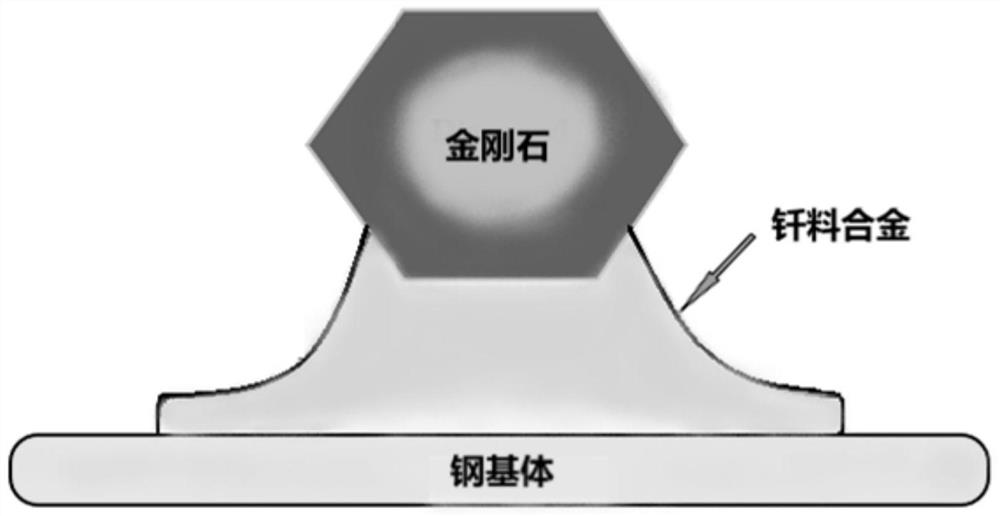

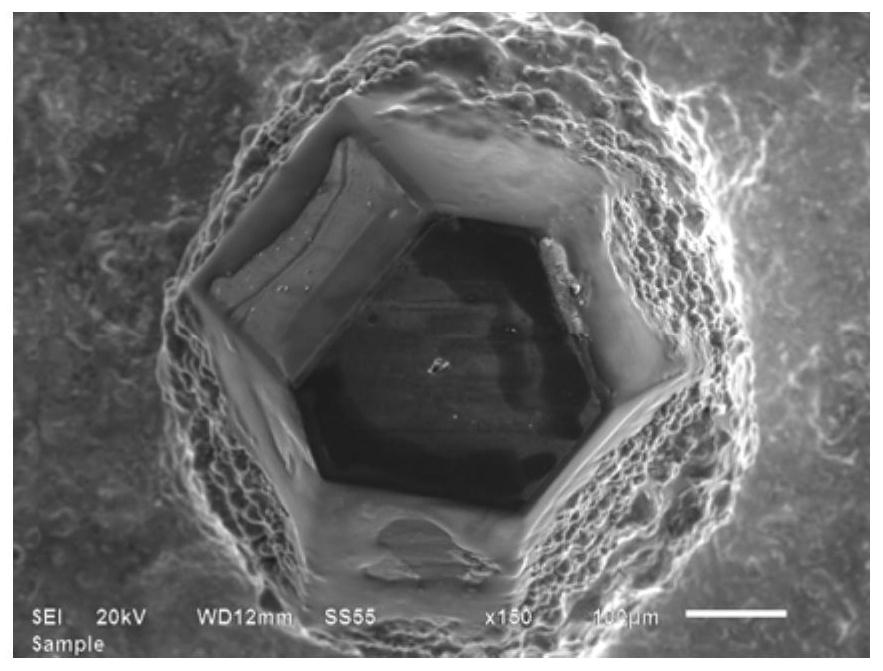

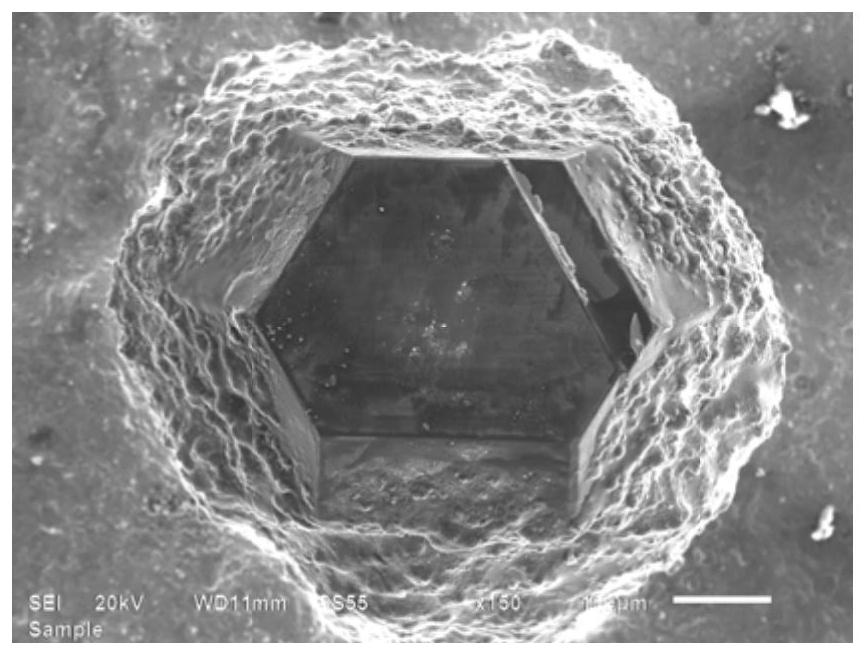

[0058] A composite brazing filler metal for superabrasive brazing in this embodiment includes a CuSnTi alloy phase and a WC-enhanced phase, wherein the CuSnTi alloy phase includes 70% Cu, 20% Sn, and 10% Ti, and the WC enhances The addition amount of the phase is 15% of the volume percentage of the CuSnTi alloy phase, the particle size of the WC reinforced phase powder in this example is 50 μm, and the superabrasive is diamond.

[0059] The composite brazing filler metal of this embodiment is used to connect diamond and Q460 steel into one body by brazing to make a diamond grinding tool. Specifically, the preparation method of the composite brazing filler metal and the brazing method of this embodiment The steps are:

[0060] (1) Uniformly mix 70% Cu powder, 20% Sn powder and 10% Ti powder by mass percentage to obtain CuSnTi alloy phase;

[0061] (2) After adding the WC reinforcing phase with a volume percentage of 15% of the CuSnTi alloy phase to the CuSnTi alloy phase, put ...

Embodiment 2

[0067] The composite brazing filler metal used for superabrasive brazing in this example is basically the same as that in Example 1. The difference is that in this example, the amount of WC reinforcing phase added is 10% of the volume percentage of the CuSnTi alloy phase, and the particle size of WC is 40 μm, and the rotational speed of the ball milling treatment was 200 r / min.

Embodiment 3

[0069]The composite brazing filler metal used for superabrasive brazing in this example is basically the same as that in Example 1, except that: in this example, the addition amount of the WC reinforcing phase is 20% of the volume percentage of the CuSnTi alloy phase, and the particle size of WC is 45 μm, and the rotational speed of the ball milling treatment was 300 r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com