Mini label printer

A printer and label technology, applied in typewriters, printing devices, printing, etc., can solve the problem of the large size of the label printer, inconvenient to carry it in a pocket, inconvenience for the printer to be stored in the pocket of clothing, and increase the thickness of the label printer, etc. problems, to achieve the effect of compact structure, reduced thickness, and reduced body size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

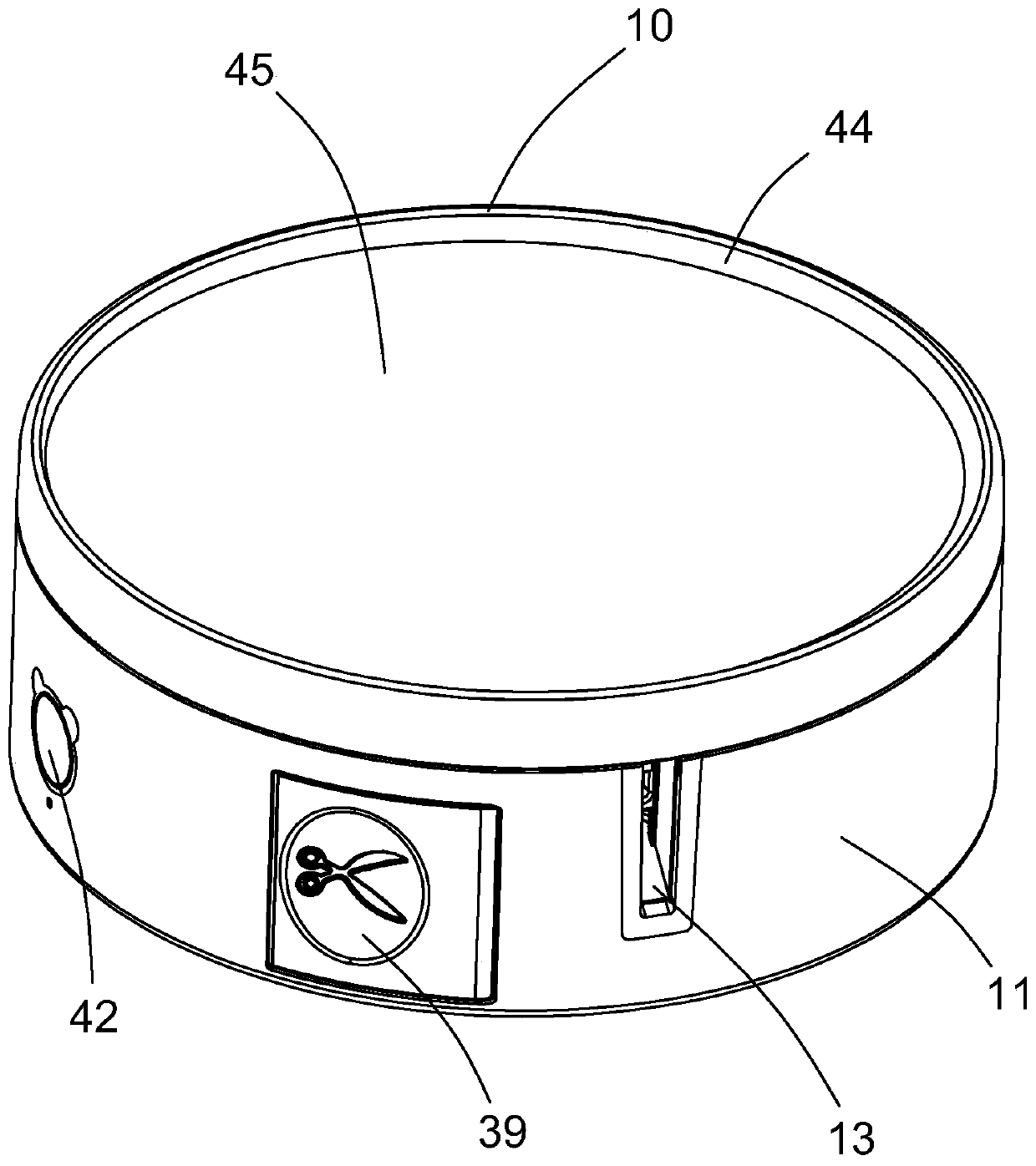

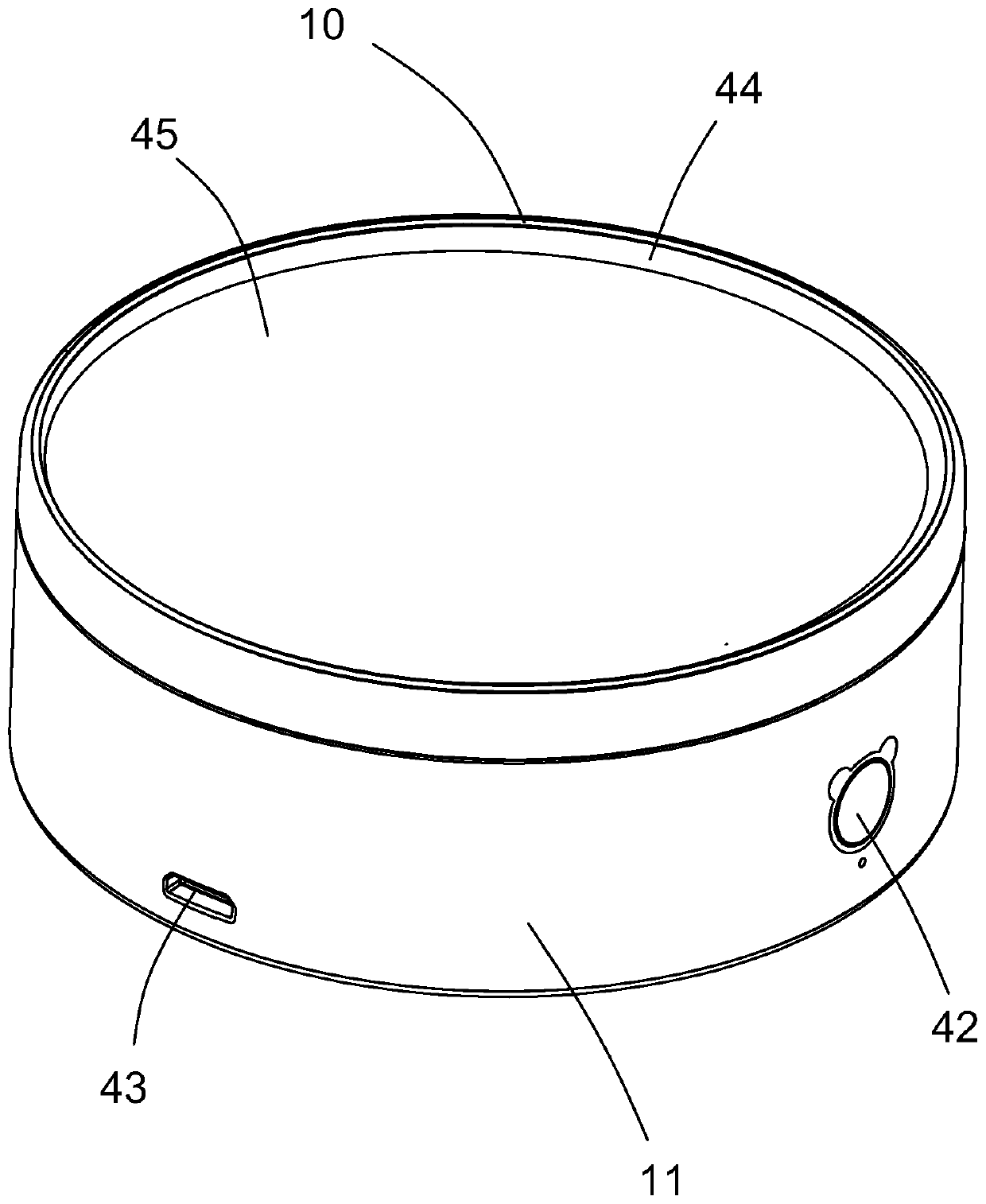

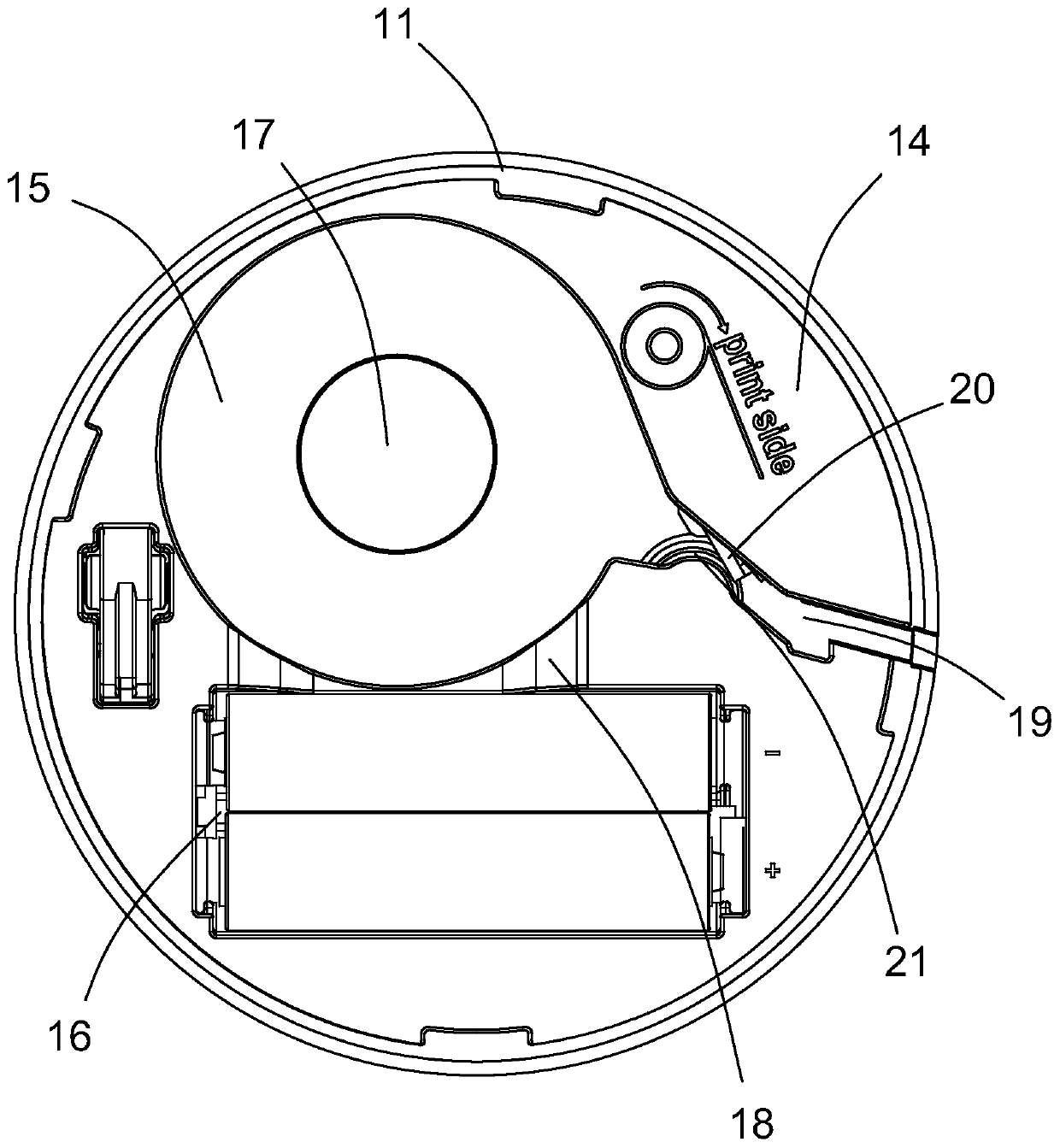

[0031] refer to Figure 1 to Figure 8 , the embodiment of the present invention discloses a mini label printer, including an upper casing 10 and a lower casing 11, and a groove 44 is opened downward on the upper end of the upper casing. The mounting plate 45, the mounting plate 45 may have a pattern itself, or the mounting plate is transparent and presents a pattern on the bottom surface of the groove, the upper shell 10 is detachably arranged on the lower shell 11, The lower end of the upper housing 10 is rotated and engaged with the card slot 12 provided at the upper end of the lower housing 11 through the clamping block, and the upper housing and the lower housing are respectively provided with the clamping block and the clamping slot. Snap marks for easier alignment of the snap entry, when the snap marks on the upper case and lower case are align...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap