Green manure organic material combined application method for improving soil fertility

A technology for improving soil and organic materials, which is applied in the direction of organic fertilizers, organic fertilizer preparation, and excretion of fertilizers. It can solve the problems of improving soil fertility without green manure and organic materials, and achieve the effects of increasing germination rate, improving effect, and improving fertility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

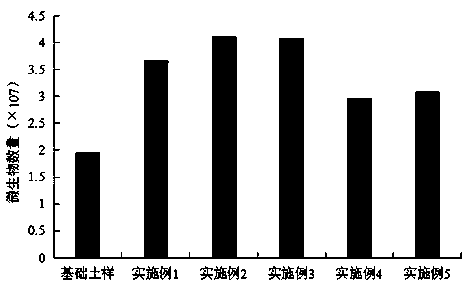

Examples

Embodiment 1

[0050] A method for compounding and applying green manure organic materials for improving soil fertility, comprising the steps of:

[0051] S1. Treatment of organic materials:

[0052] a. Put the crop stalks into the straw grinder for crushing treatment. The speed of the grinder is 600rpm, and the crushing process is 30min. Then, the crushed crop straws are immersed in the treatment solution. After 20kHz ultrasonic vibration treatment for 1h, the soaked crop Put the straw treatment liquid into the reactor, raise the temperature in the reactor to 100°C, raise the pressure in the reactor to 0.3MPa, maintain the temperature and pressure for 10 minutes, quickly release the pressure to normal pressure, filter out the crop straw and dry it After drying, the components and the corresponding weight percentages in the treatment liquid are: 0.2% sodium hydroxide, 2% ethylenediamine, 5% Tween, 0.6% decanoyl acetaldehyde, and the balance is deionized water;

[0053] b. Put decomposing ag...

Embodiment 2

[0062] A method for compounding and applying green manure organic materials for improving soil fertility, comprising the steps of:

[0063] S1. Treatment of organic materials:

[0064] a. Put the crop stalks into the straw grinder for crushing treatment. The speed of the grinder is 700rpm, and the crushing process is 35 minutes. Then the crushed crop straws are immersed in the treatment solution. Put the treatment solution of crop straw into the reactor, raise the temperature in the reactor to 110°C, raise the pressure in the reactor to 0.4MPa, maintain the temperature and pressure for 18 minutes, quickly release the pressure to normal pressure, and filter out the crop straw After drying, it is used for later use, wherein the components and corresponding weight percentages in the treatment liquid are: 0.25% sodium hydroxide, 2.5% ethylenediamine, 6% Tween, 0.7% decanoyl acetaldehyde, and the balance is deionized water ;

[0065] b. Put the decomposing agent, farm manure and ...

Embodiment 3

[0074] A method for compounding and applying green manure organic materials for improving soil fertility, comprising the steps of:

[0075] S1. Treatment of organic materials:

[0076] a. Put the crop stalks into the straw grinder for crushing treatment. The speed of the grinder is 800rpm, and the crushing process is 340min. Then, the crushed crop straws are immersed in the treatment solution, and after 50kHz ultrasonic vibration treatment for 2 hours, the soaked crops Put the straw treatment solution into the reactor, raise the temperature in the reactor to 120°C, raise the pressure in the reactor to 0.5MPa, maintain the temperature and pressure for 26 minutes, quickly release the pressure to normal pressure, filter out the crop straw and dry it. After drying, the components and the corresponding weight percentages in the treatment liquid are: 0.3% sodium hydroxide, 3% ethylenediamine, 7% Tween, 0.8% decanoyl acetaldehyde, and the balance is deionized water;

[0077] b. Put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com