Thermolizing processing device for mechanical metal part

A technology for surface heat treatment and metal parts, applied in the field of heat treatment, can solve the problems of insufficient uniform heating area, affecting the heat treatment effect, and inability to adjust the lifting and lowering, to achieve uniform heating area, improve functionality and practical value, and improve the effect of heat treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

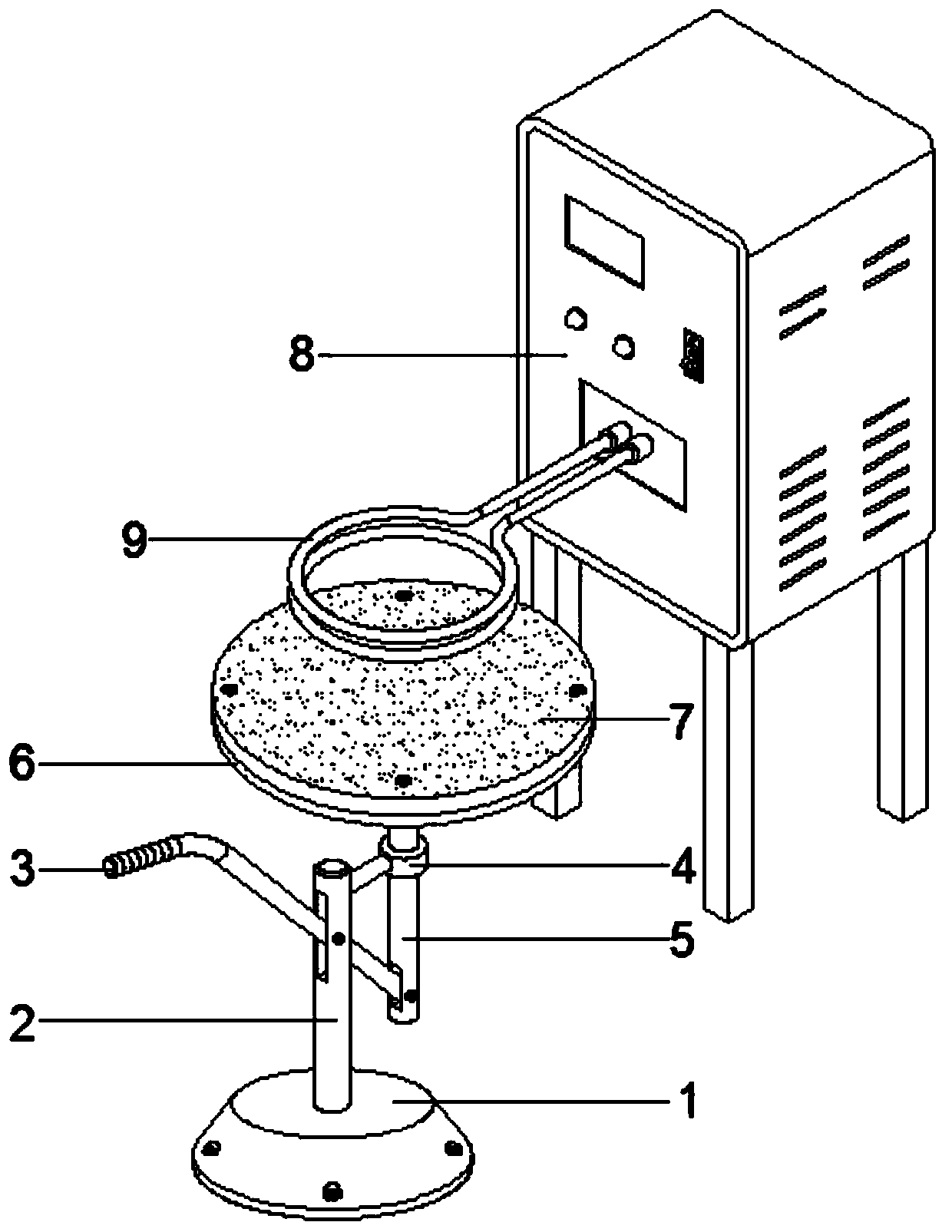

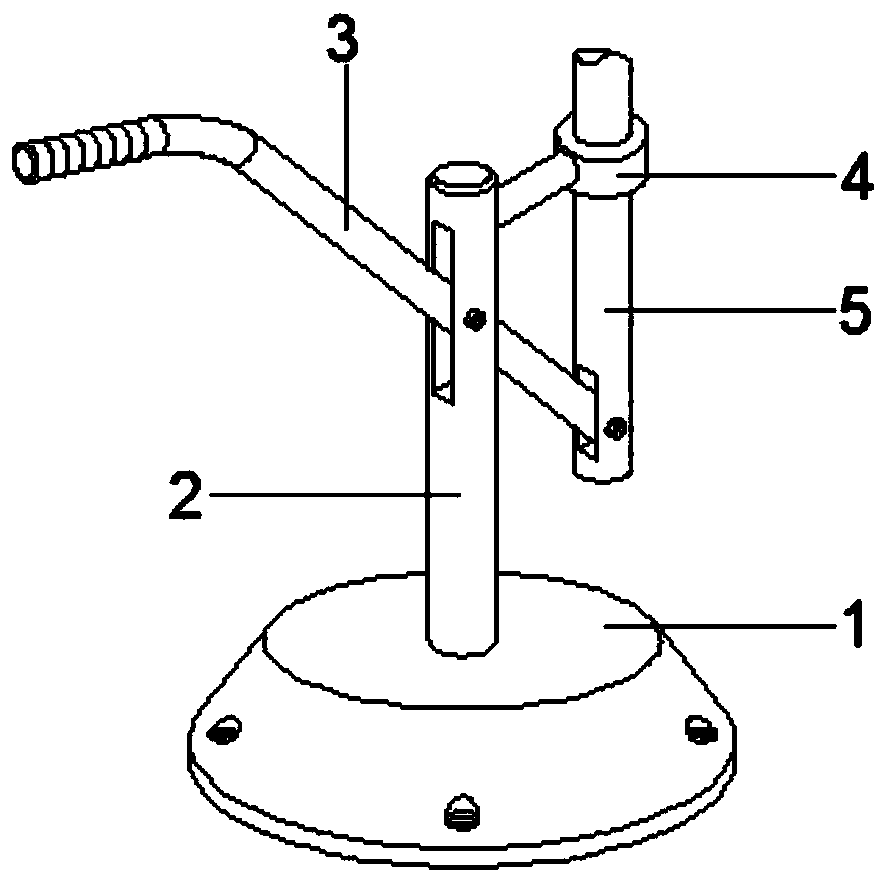

[0025] A surface heat treatment processing device for mechanical metal parts, comprising: a base 1, a column 2, a pressure rod 3, a sliding sleeve 4, a push rod 5, a fixed plate 6, a heat shield 7, a high-frequency heater 8, and a high-frequency coil 9; The upper part of the base 1 is provided with a column 2, and the base 1 and the column 2 are connected by welding; the pressure rod 3 is arranged in the middle of the column 2, and the pressure bar 3 and the column 2 are connected by a hinge; the sliding sleeve 4 is arranged on the column 2 on one side of the upper part, and the sliding sleeve 4 is connected with the column 2 by welding; the ejector rod 5 is arranged at one end of the pressure rod 3, and the ejector rod 5 and the pressure rod 3 are connected by a hinge; the fixed plate 6 is arranged on the top The top of the rod 5, and the fixed plate 6 is connected with the ejector rod 5 by welding; the heat insulating plate 7 is arranged on the upper part of the fixed plate 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com