High-strength composite flexible channel structure

A high-strength, channel technology, applied in the field of field channels, can solve the problems of low strength, deformation, affecting the aesthetics of channels, etc., and achieve the effect of simple and reasonable structure, convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

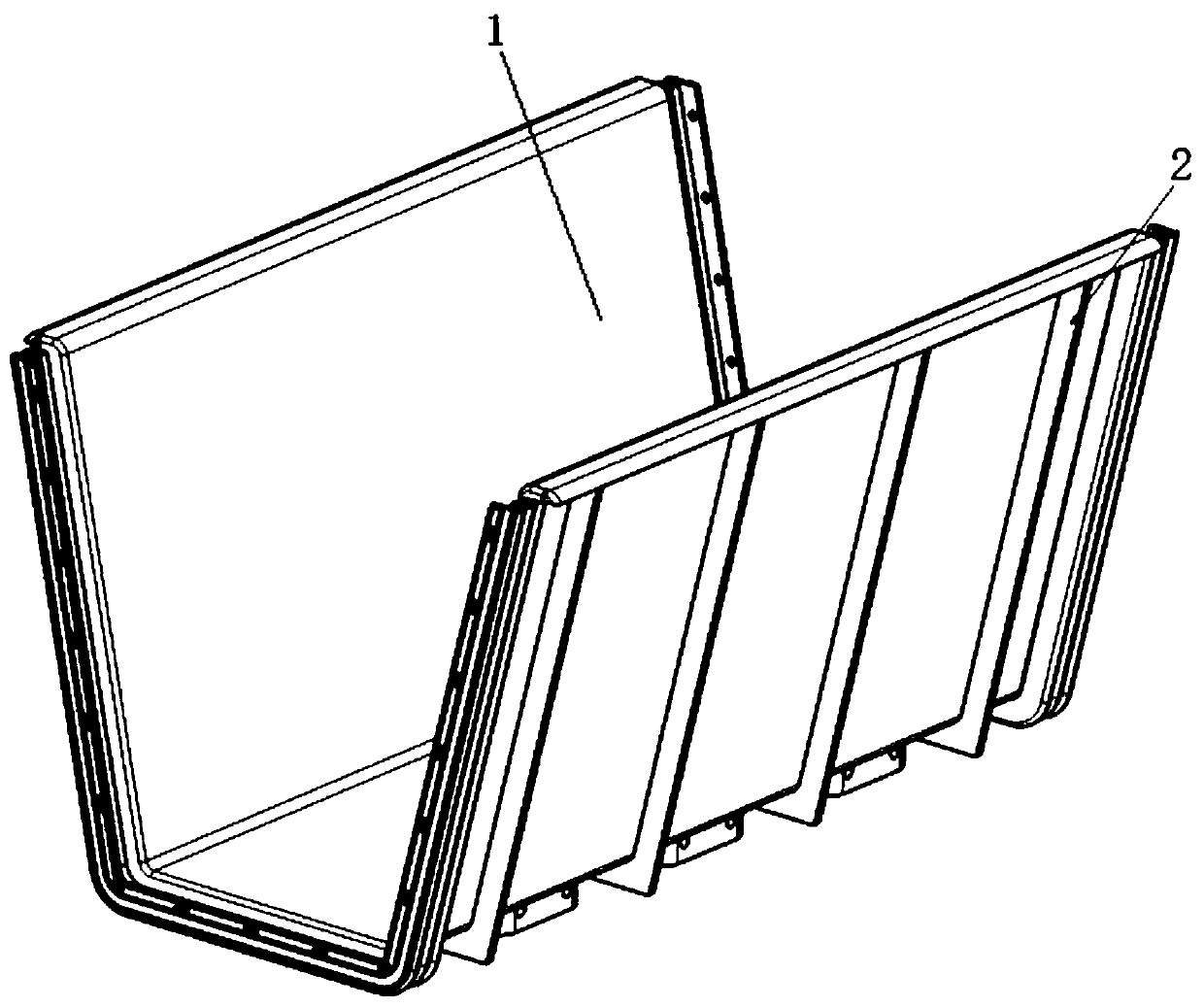

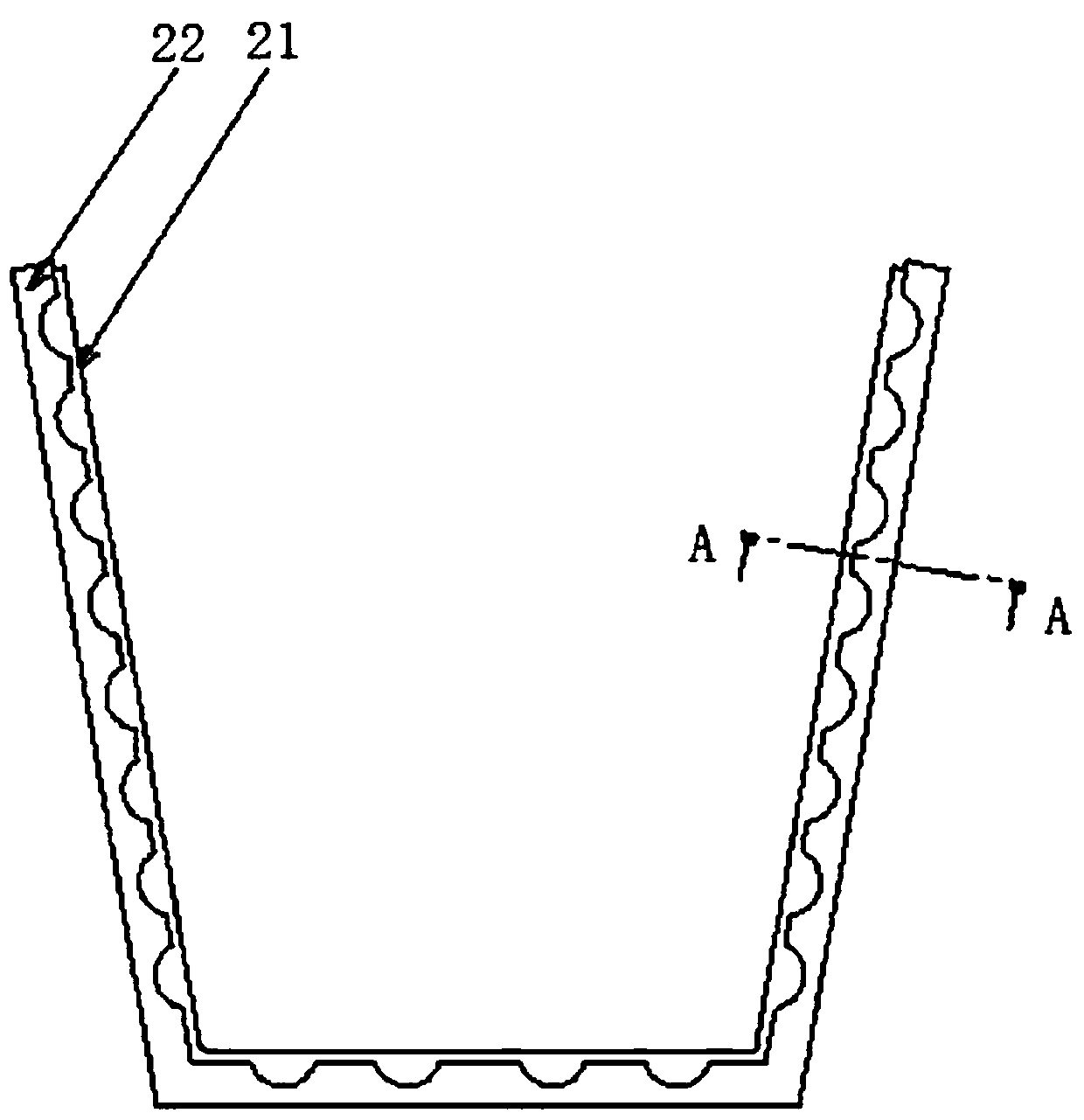

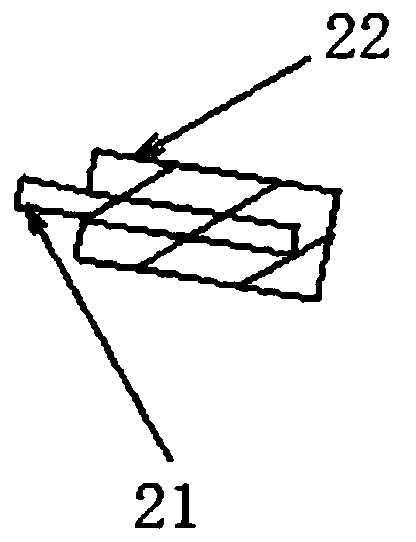

[0028] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a high-strength composite flexible channel structure provided by the embodiment of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the structure includes a flexible channel main body 1 and a channel skeleton component 2, the flexible channel main body 1 and the channel skeleton component 2 are combined to form an integral structure; the inner side of the flexible channel main body 1 is used to form a water flow channel, and the The channel skeleton assembly 2 is used to ensure that the cross-sectional shape of the flexible channel body 1 remains unchanged when the flexible channel body 1 is subjected to an external force. The flexible channel main body 1 and the channel skeleton component 2 are compounded by any one of compound injection molding process and molding process to form an integral structure. In the structure provided by the present applicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com