Critical liquid-carrying flow calculation method considering droplet deformation and multi-parameter influence

A liquid-carrying flow rate and calculation method technology, which is applied in the field of reasonable production allocation of gas reservoirs, can solve problems such as deviations in the judgment of liquid accumulation in gas wells, changes in key parameters, and inability to accurately reflect the normal liquid-carrying production capacity of gas wells, etc., so as to achieve convenient reference , Calculate the effect of accurate and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

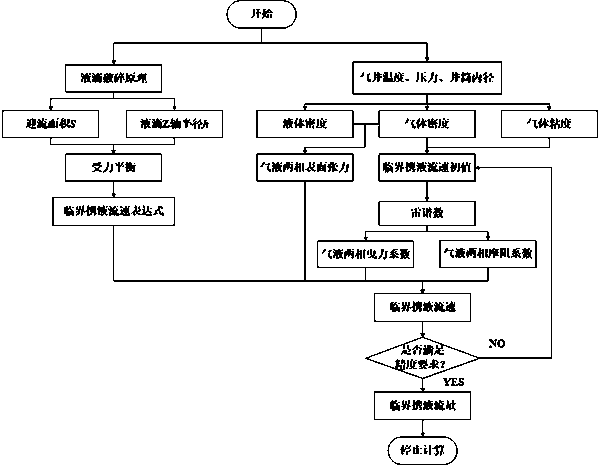

[0015] Such as figure 1 Shown is the flow chart of calculation of the critical liquid-carrying flow of the present invention, and the present invention adopts the following steps:

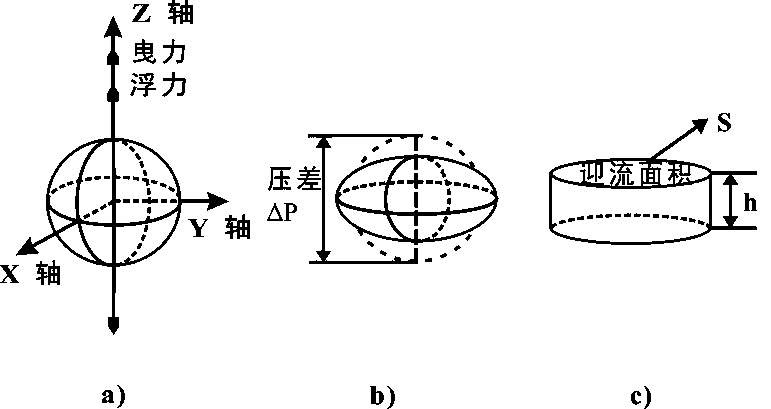

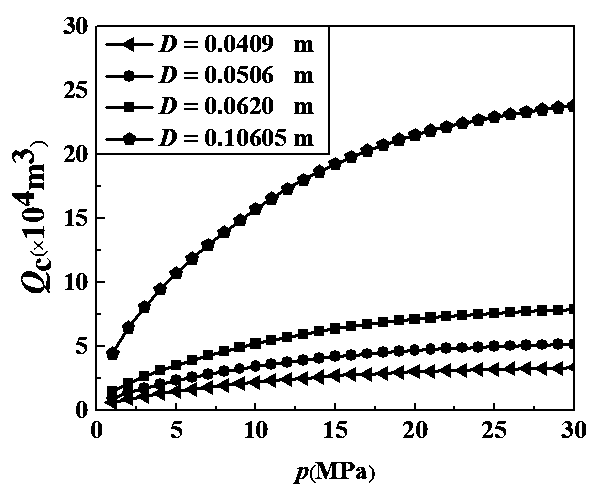

[0016] Firstly, the physical model of the droplet in the wellbore is established, based on the principle of droplet breakage microscopically, that is, the droplet is kept in an ellipsoidal shape without being broken by surface tension and gas phase turbulent force, and the maximum size parameter of the ellipsoidal droplet is calculated; then, Macroscopically, based on the balance of gravity, drag force and buoyancy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com