Fabric surface defect detection method based on convolutional neural network

A convolutional neural network and defect detection technology, applied in the field of fabric surface defect detection, can solve the problems of time-consuming and labor-intensive execution process, and the accuracy and speed are difficult to meet the requirements, achieving high training efficiency, reducing classification difficulty, strong adaptability and robustness. awesome effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

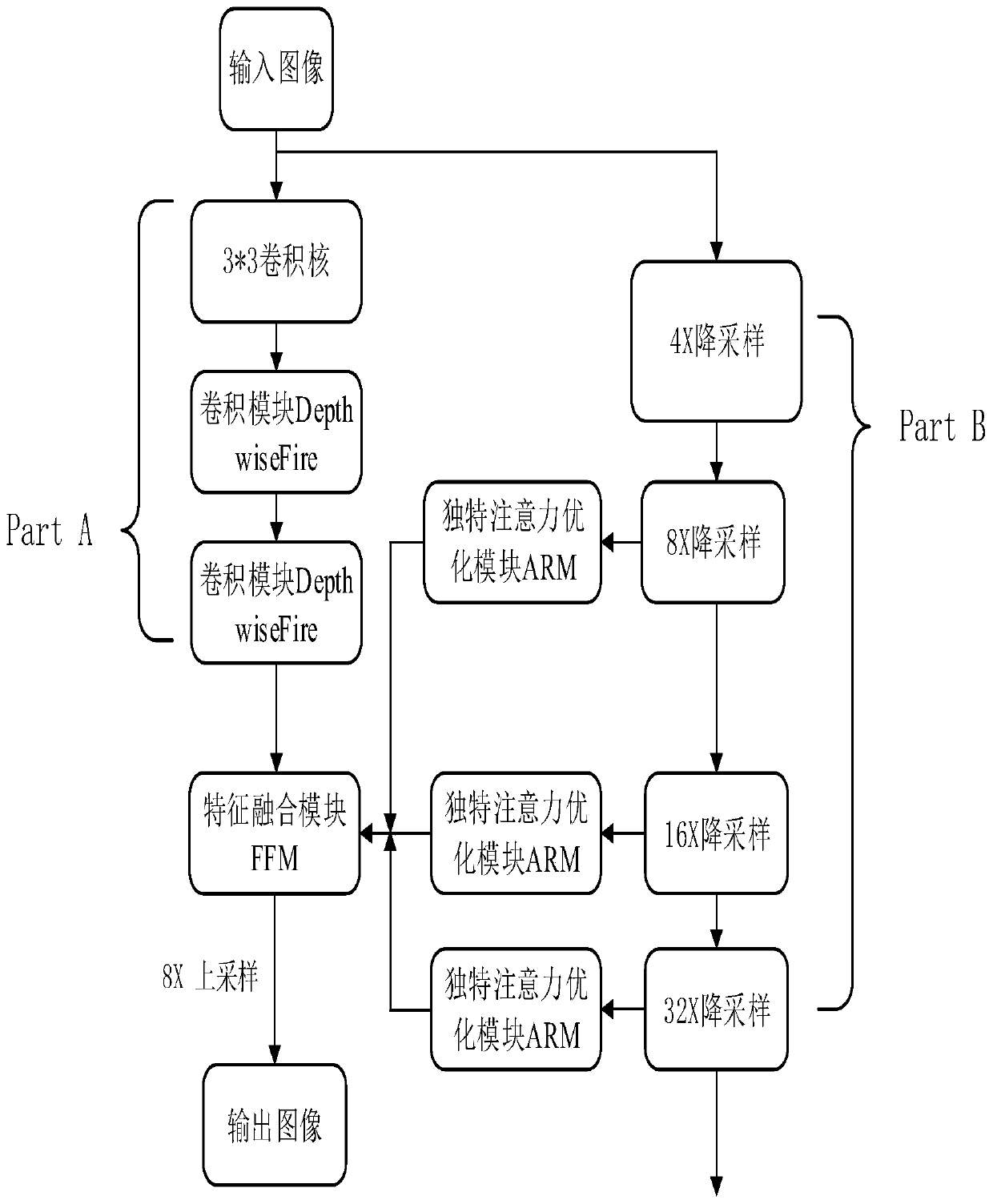

[0048] Embodiment 1: a kind of fabric surface defect detection method based on convolutional neural network of the present embodiment comprises the following steps:

[0049] S1. Collection and labeling of data sets: collect and mark images of several types of fabric surface defect sample sets, and collect one type of normal samples for labeling, and use the collected above sample images as a data set;

[0050] S2. GroundTruth for making defect sample images in the data set: divide all defect sample images in the data set into a training set and a verification set in a ratio of 8:2;

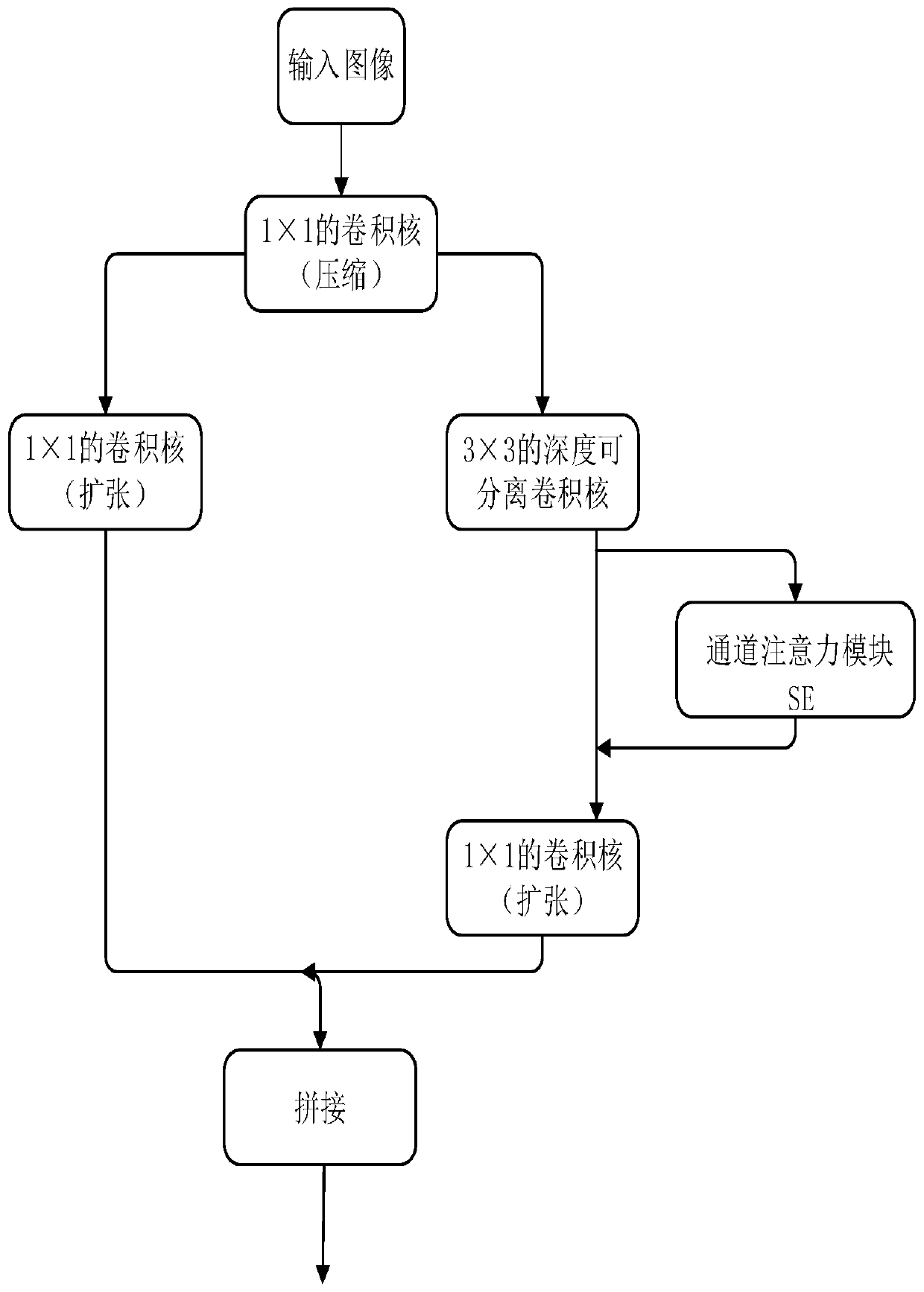

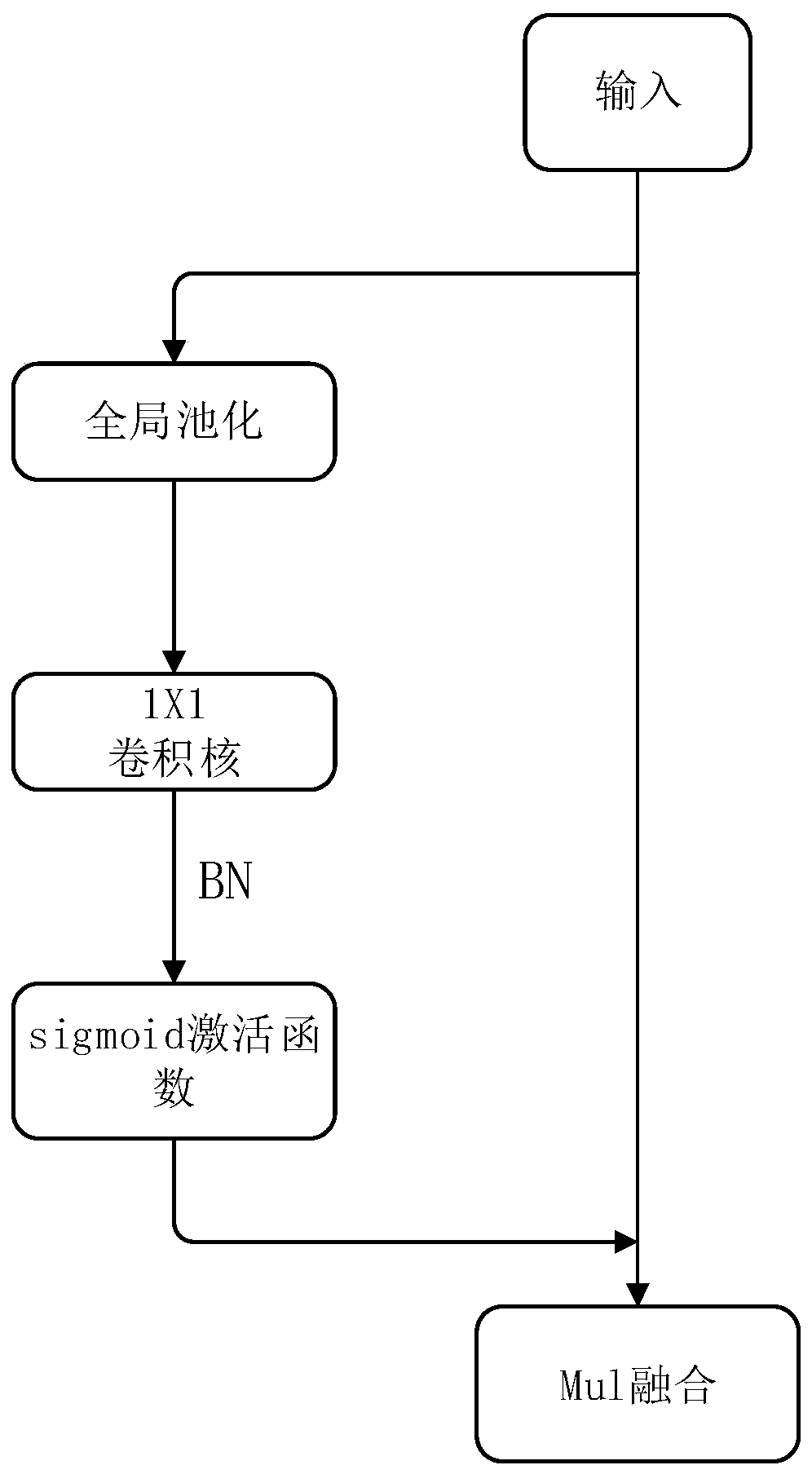

[0051] S3, building a convolutional neural network model;

[0052] S4, training the convolutional neural network model to obtain the optimal model;

[0053] S5. Collect the defect image of the fabric online, input the image of the fabric to be detected into the above-mentioned trained convolutional neural network model for image segmentation, and realize online automatic detection through the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com