Wafer Stripping Device

A technology for stripping devices and wafers, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of wasting human resources, affecting operation efficiency, increasing labor costs, etc., and achieves saving production resources, equipment and machinery relations Excellent, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

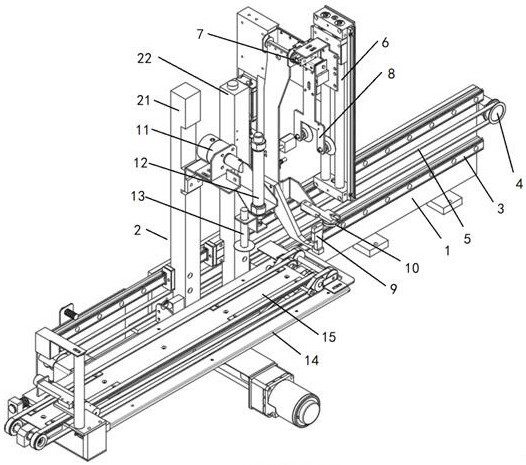

[0023] The invention discloses a wafer stripping device used in the wafer processing process, specifically as follows.

[0024] Such as figure 1 As shown, a wafer stripping device is fixedly connected to the external equipment frame 1, including a stripping actuator integrally movably arranged on the external equipment frame 1, used to complete the wafer stripping operation, and an integrally fixed connection On the external equipment frame 1 , it is used to complete the transfer execution mechanism for wafer delivery. The stripping actuator includes a wafer suction assembly and a wafer turning assembly. Under the cooperative operation of the wafer suction assembly and the wafer turning assembly, the wafers carried on the external wafer supporting mechanism (not shown in the figure) are peeled off one by one and moved to the on the transmission actuator.

[0025] The peeling actuator includes a mechanism support frame 2, and the external equipment frame 1 is fixedly provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com