Battery pack box body and battery pack with same

A battery pack and box technology, applied in the field of battery module processing, can solve the problems of restricting large-scale promotion and application, the effect of light weight is not obvious, and restricting promotion and application, so as to improve the ability to resist bottom impact damage and improve the resistance to ground Injury ability, safety performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

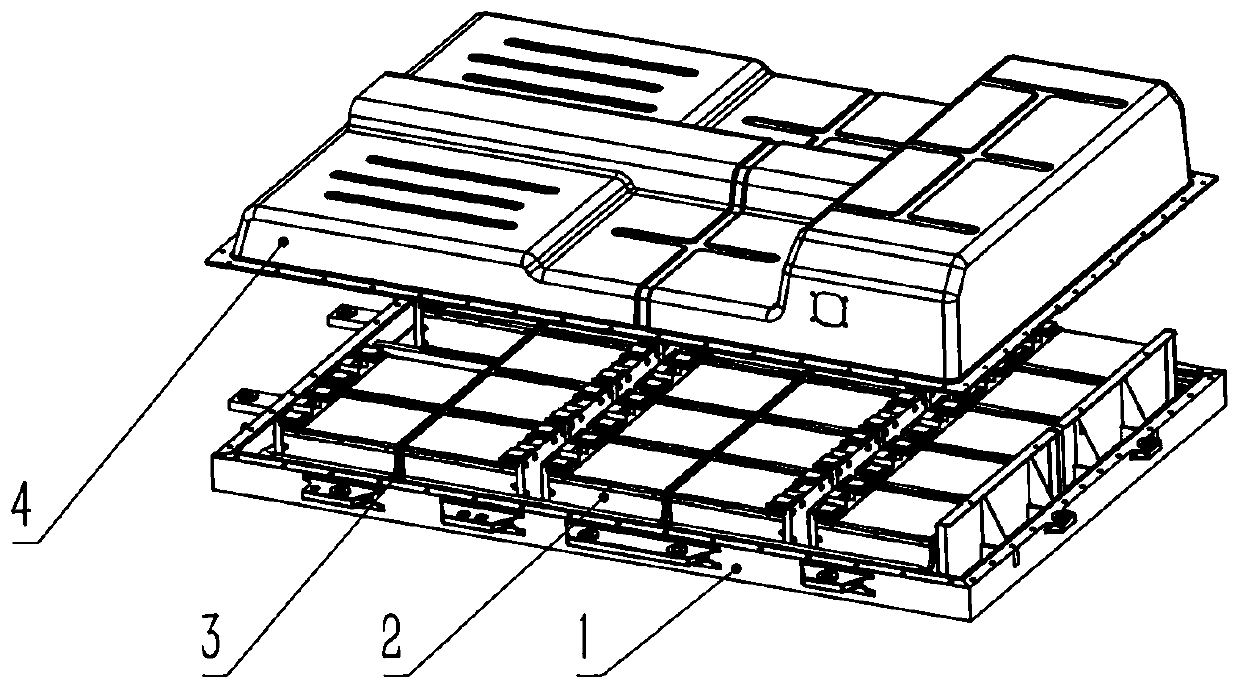

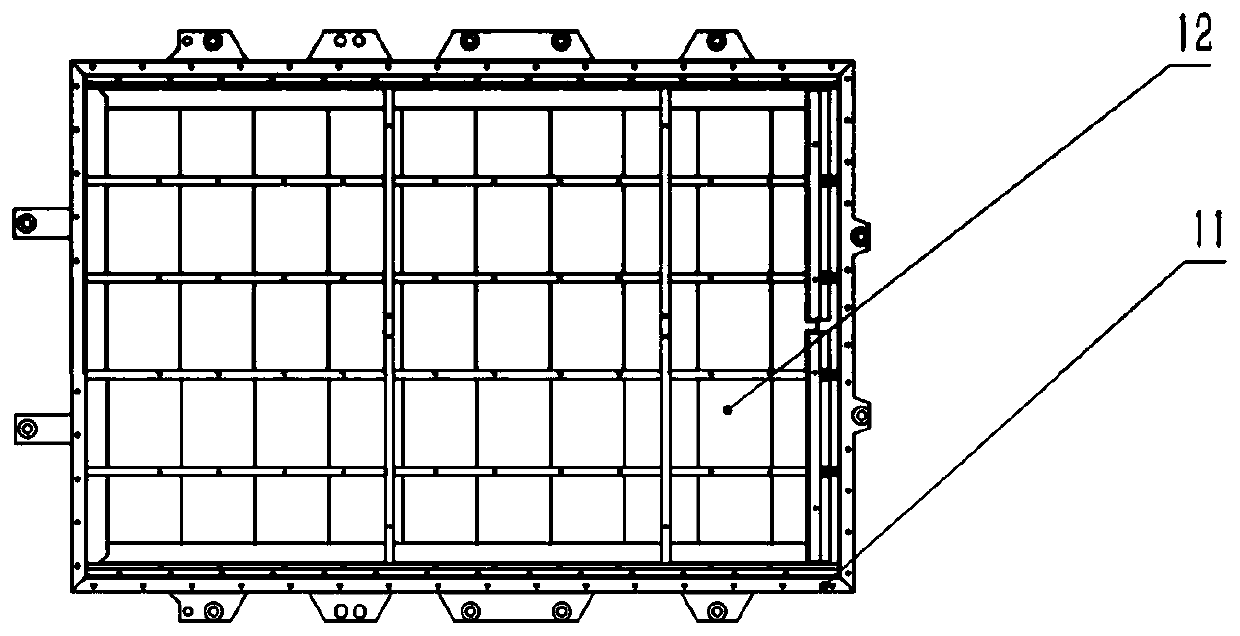

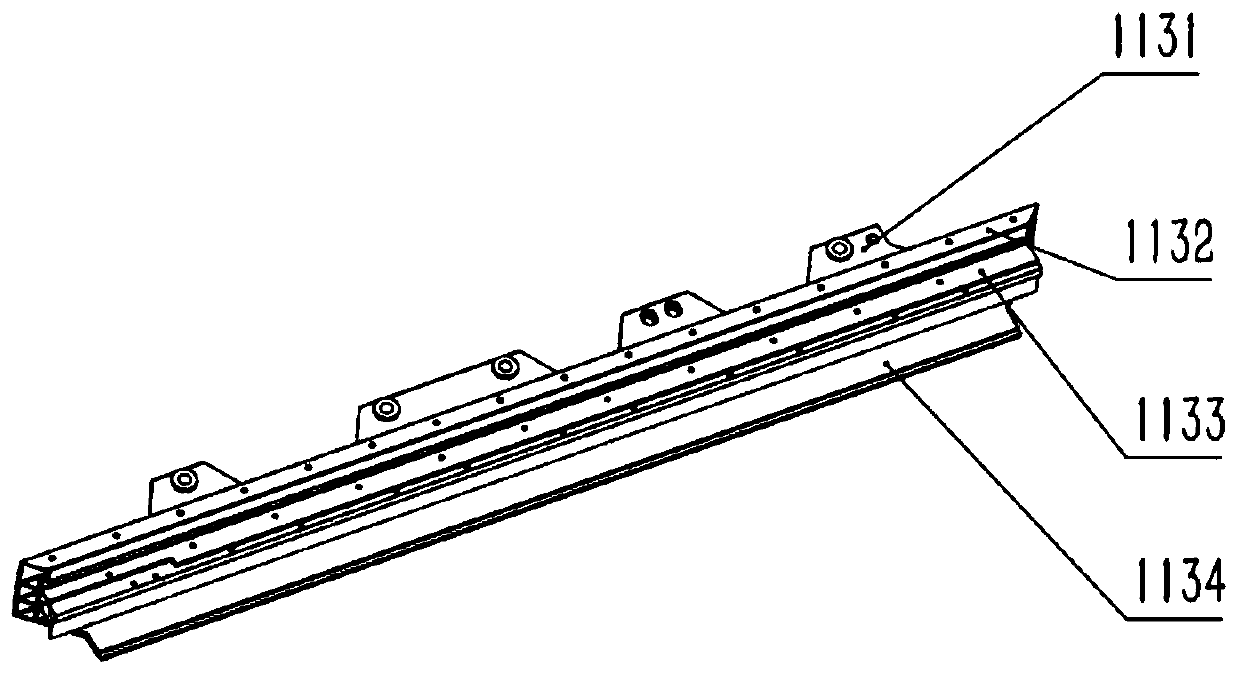

[0055] refer to Figures 1 to 25 As shown, a battery pack case of this embodiment includes a lower case 1, an upper cover 4 disposed on the upper end of the lower case 1, a mounting portion disposed on the periphery of the lower case 1, and a mounting portion arranged on the lower case 1. The battery accommodating cavity between the upper cover 4, the lower box 1 includes a frame 11 and a spliced bottom plate 12 arranged in the frame 11, and the frame 11 includes a first main beam 1122 and a second main beam 1132 arranged vertically ; The inside of the first main beam 1122 is provided with a first connection part that matches the spliced bottom plate 12; the inside of the second main beam 1132 is provided with a second connection part that matches the spliced bottom plate 12, and the installation part includes hanging ears 1123 and hardpoint 1131.

[0056] The box body is composed of an upper cover 4 and a lower box body 1. The lower box body 1 is composed of a frame 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com