Main and auxiliary cavity coupling type self-adaptive cyclone centrifugal degassing method and device

A degassing device, coupled technology, applied in the direction of a cyclone device, a device whose axial direction of the cyclone can be reversed, etc., can solve the problem of increased energy consumption, increased separation difficulty, and degassing efficiency not greater than 90%, etc. problems, to achieve the effect of improved degassing efficiency, advanced separation time, and rapid and sufficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

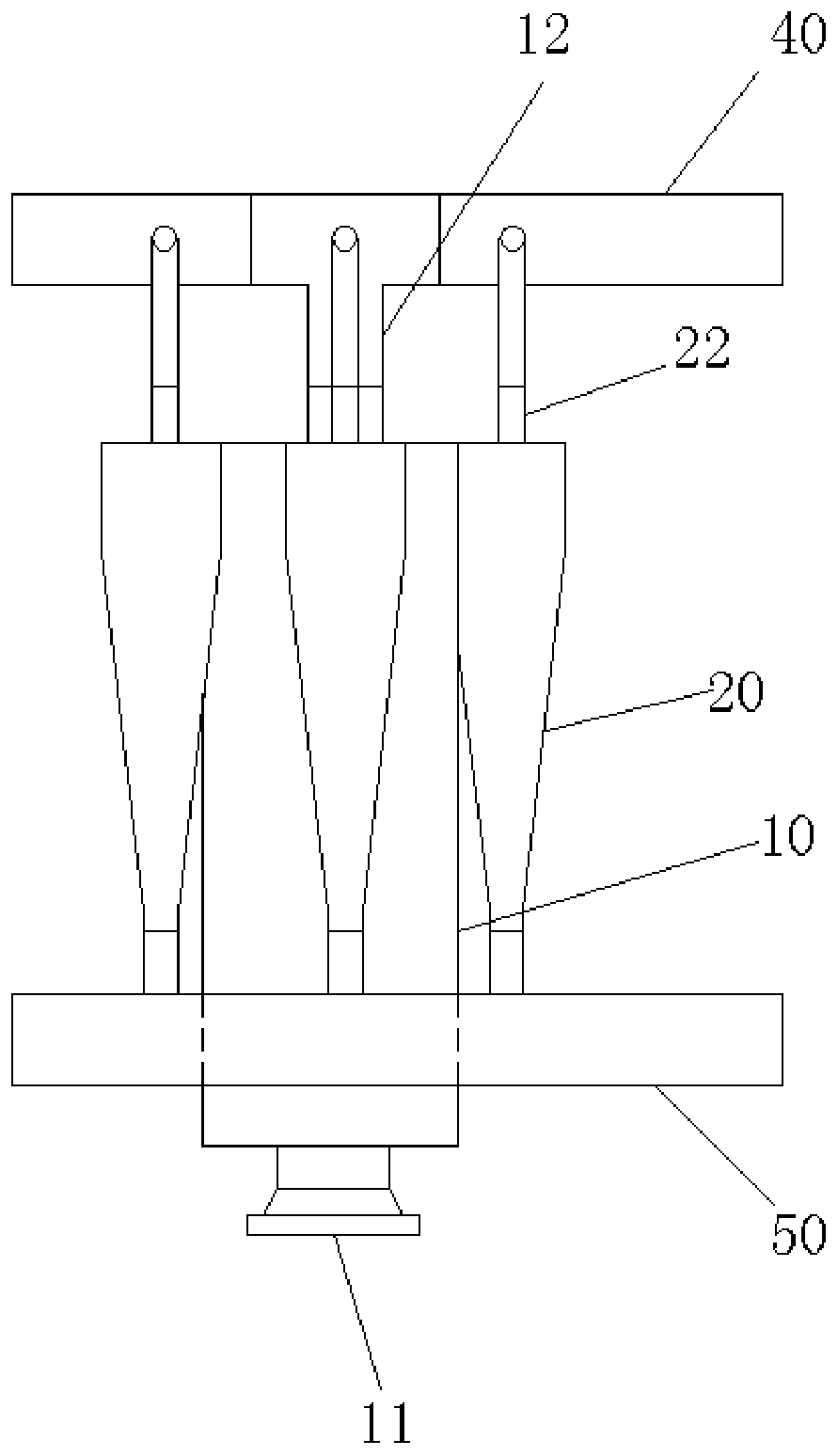

[0077] Such as Figure 1 to Figure 6 As shown, the main and auxiliary cavity coupled adaptive cyclone centrifugal degassing device of this embodiment has a basic structure including a main cyclone 10, five auxiliary cyclones 20, and connecting the main cyclone 10 and the auxiliary cyclone 5 coupling channels 30 of the device 20; wherein:

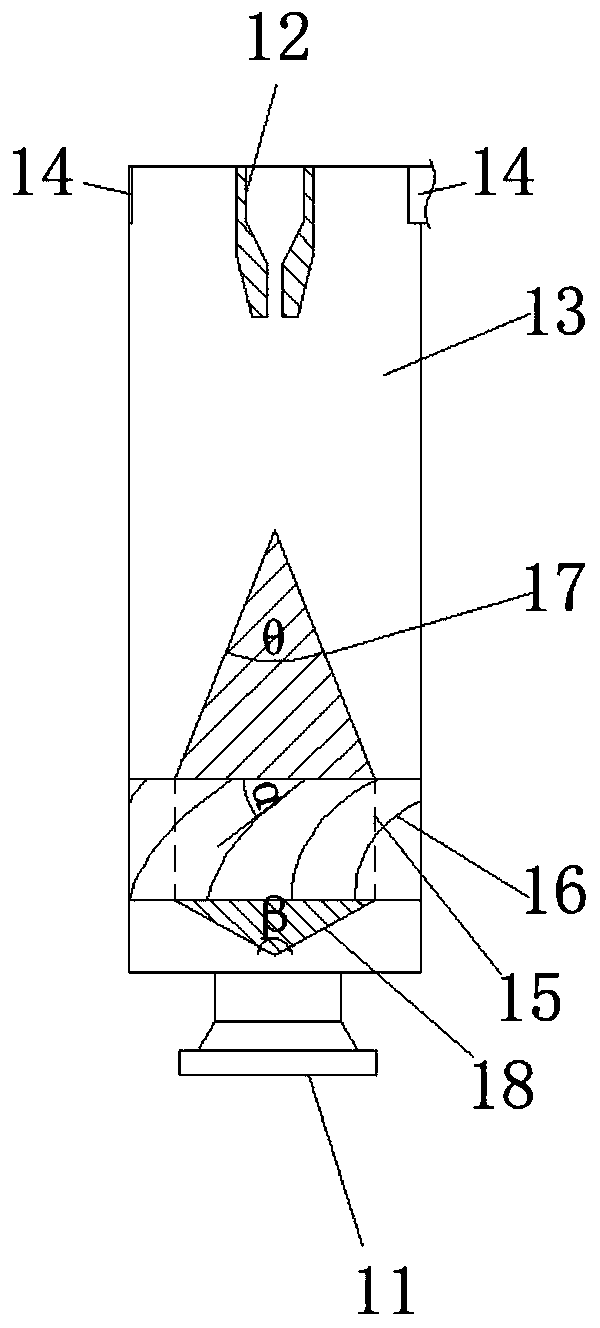

[0078] The main cyclone 10 is a cylindrical structure, the bottom of the main cyclone 10 is provided with an axial-flow type main cyclone inlet 11, the top is provided with an overflow pipe 12, and there is a main cyclone cavity 13 inside, A diversion structure is installed in the main swirl cavity 13, and five tangential liquid outlets 14 are arranged tangentially and uniformly on the side wall of the upper part of the main swirl 10;

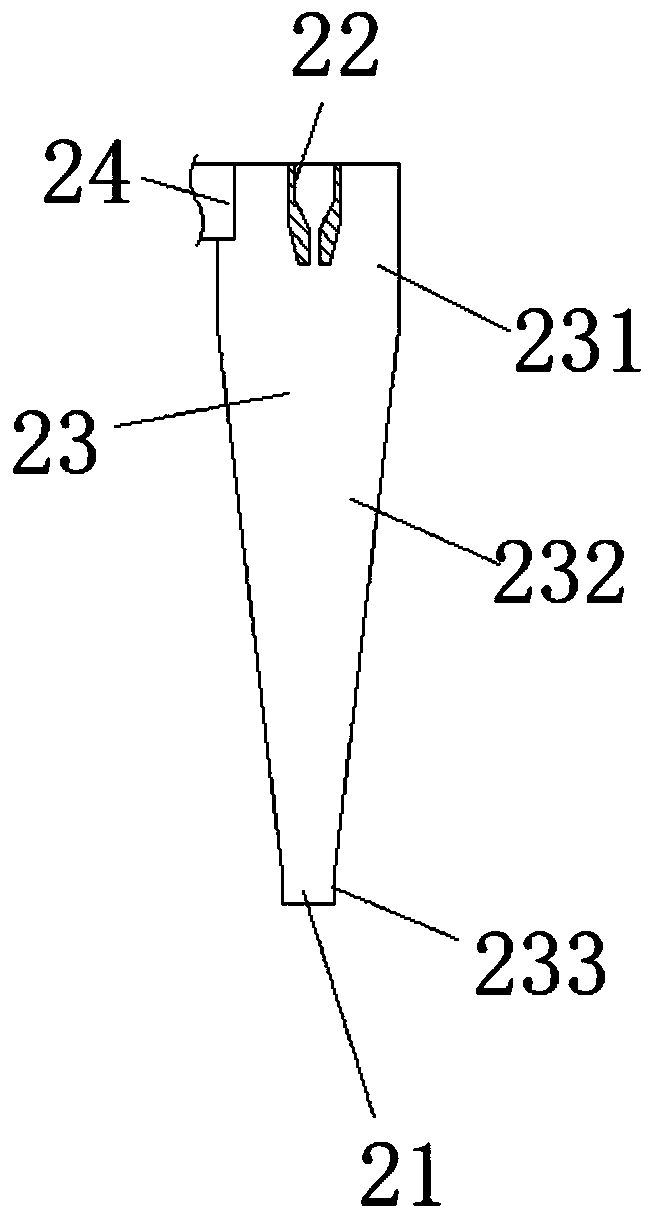

[0079] The secondary cyclone 20 is a column-conical structure, the bottom of the secondary cyclone 20 is provided with a secondary cyclone outlet 21, the top is provided with an overflow pipe 22, and there i...

Embodiment 2

[0097] Such as Figure 7 shown. The basic structure of the main-sub-chamber coupled self-adaptive cyclone centrifugal degasser in this embodiment is the same as that of Embodiment 1, the difference is that the rotation direction of the material in the secondary cyclone chamber is the same as that of the material in the main cyclone chamber. The rotation directions are opposite, and the number of the secondary swirlers 20 and the coupling channels 30 is four.

Embodiment 3

[0099] The basic structure of the main and auxiliary cavity coupled adaptive cyclone centrifugal degassing device of this embodiment is the same as that of Embodiment 1, the difference lies in the structure of the overflow pipe. in particular:

[0100] Such as Figure 8 As shown, the inner cavity of the overflow pipe (12,22) includes an upper cylindrical cavity (121,221), an upper conical cavity (122,222), a lower cylindrical cavity (123,223) and a lower conical cavity (124,224) connected in sequence; The apex angles of the upper conical cavity (122, 2212) and the lower conical cavity (124, 224) are the same, the apex of the upper conical cavity (122, 222) faces downward, and the apex of the lower conical cavity (124, 224) faces upward. The cone tip angle γ of the upper conical cavity (122, 222) and the lower conical cavity (124, 224) is 20-40°.

[0101] In this way, the cone top of the upper conical chamber (122, 2212) faces downwards, and gradually expands upward to form a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com