Grain processing device

A processing device and grain technology, which is applied in the direction of heating device, drying solid materials, dry goods processing, etc., can solve the problems of high labor intensity, hard to immerse the grain pile in water, and difficult to clean, so as to improve the utilization rate and improve the drying efficiency. Efficiency, the effect of improving cleaning efficiency and cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

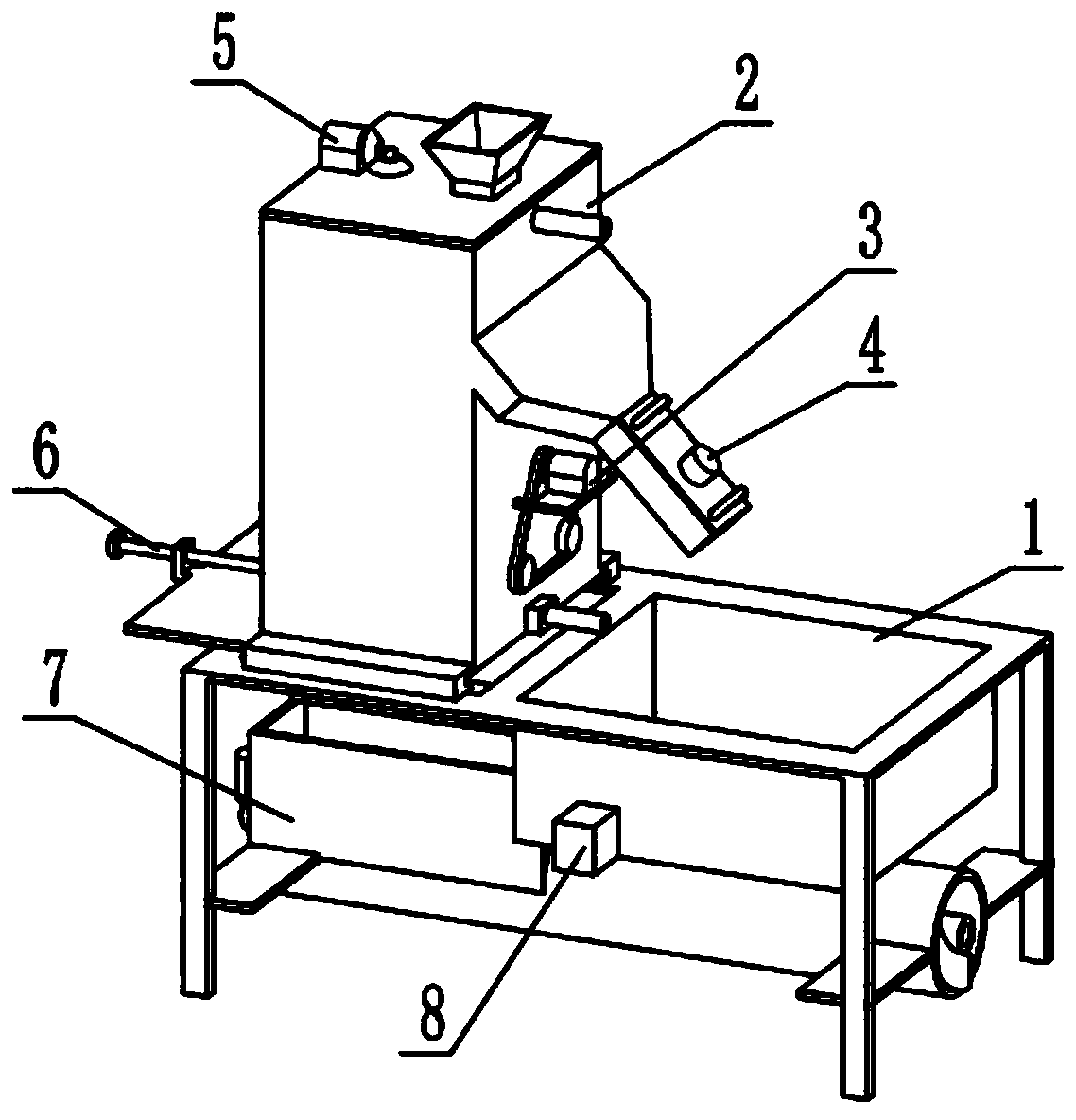

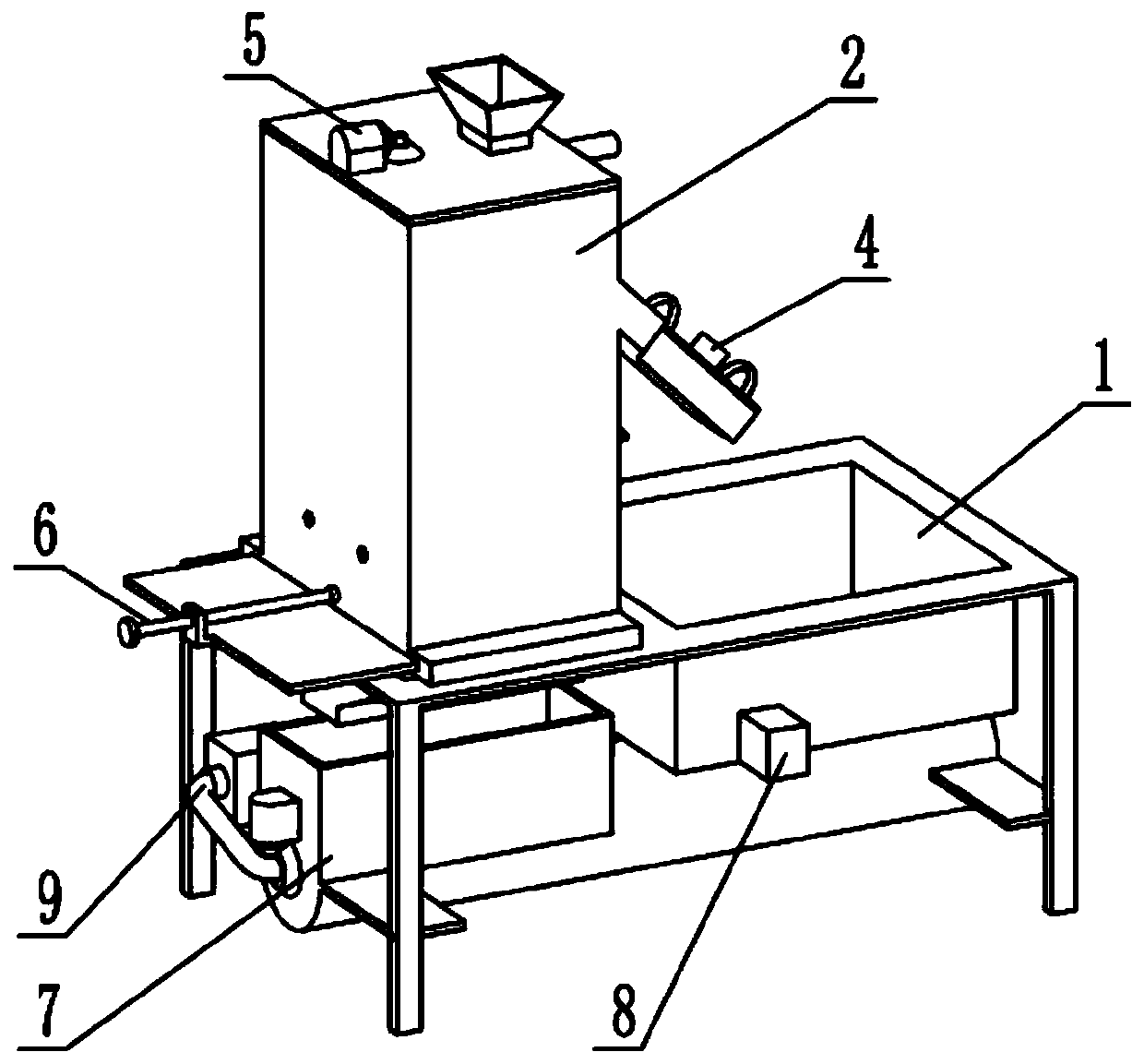

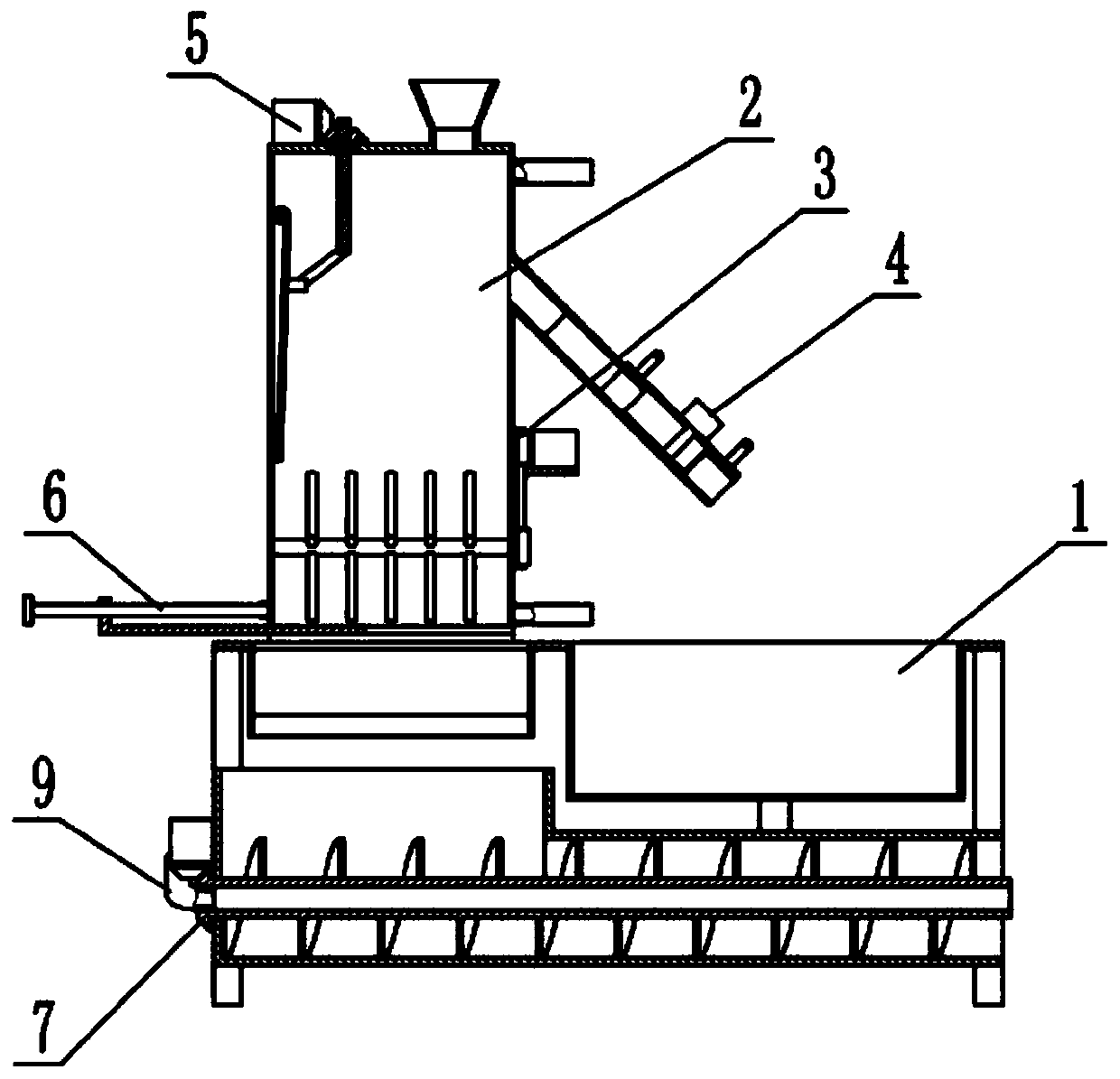

[0031] Such as Figure 1-13 As shown, a grain processing device includes a support frame 1, a cleaning container 2, a stirring mechanism 3, a filtering and collecting device 4, a baffle mechanism 5, a bottom sealing mechanism 6, a drying device 7, a water pump 8 and a blower 9. The cleaning container 2 is fixedly connected to the support frame 1, the stirring mechanism 3 is rotatably connected to the lower part of the cleaning container 2, the filter collection device 4 is connected to the cleaning container 2, and the baffle plate The mechanism 5 is connected to the upper part of the cleaning container 2, the bottom sealing mechanism 6 is connected to the lower end of the cleaning container 2, the drying device 7 is fixedly connected to the lower end of the support frame 1, and the water pump 8 is fixedly connected to On the support frame 1 and communicated with the cleaning container 2, the blower 9 is connected with the drying device 7;

[0032]When in use, the grain is fi...

specific Embodiment approach 2

[0034] Such as Figure 1-13 As shown, the support frame 1 includes a main board 1-1, a water tank 1-2, a support leg 1-3, a concentration board 1-4 and a drain pipe 1-5, and the four corners of the main board 1-1 are fixedly connected with supports The legs 1-3, the water tank 1-2 and the concentration plate 1-4 are all fixedly connected on the main board 1-1, the lower end of the water tank 1-2 is provided with a drain pipe 1-5, and the drain pipe 1-5 is provided with a valve and a water pump 8 is fixedly connected to the outside of the water tank 1-2 and communicated with the water tank 1-2;

[0035] The supporting legs 1-3 are used to support the device on the ground, the concentrating plate 1-4 is used to concentrate the falling grains in the container body 2-1 into the feeding port 7-3, and the water tank 1-2 is used for water storage. Drain pipe 1-5 is used for draining the water of water tank 1-2.

specific Embodiment approach 3

[0037] Such as Figure 1-13 As shown, the cleaning container 2 includes a container body 2-1, an upper cover plate 2-2, a hopper 2-3, a water inlet pipe 2-4, a miscellaneous discharge pipe 2-5, a fixed plate 2-6, Slideway base 2-7, drainage head 2-8, rotating seat 2-9 and fixed shaft 2-10, the upper end of containing box body 2-1 is fixedly connected with upper cover plate 2-2, upper cover plate 2-2 The feeding hopper 2-3 is fixedly connected, and the both sides of the lower end of the box body 2-1 are fixedly connected with a slideway base 2-7, and the two slideway bases 2-7 are fixedly connected on the main board 1-1, and the box body 2 -1 is located directly above the concentrating plate 1-4, the water inlet pipe 2-4 is fixedly connected to the upper end of the storage box 2-1, and the miscellaneous discharge pipe 2-5 is obliquely fixedly connected to the side of the storage box 2-1 for miscellaneous discharge The lower end of the pipe 2-5 is provided with a valve, the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com